The Fixer

Perplexing Pistol Problems Resolved

A few years back I got a call from my good friend Jim Martin — a single-action sixgunsmith in Arizona. He’d called to tell me he had a .44 Special New Frontier for sale belonging to one of his customers.

The Right Bullet

My interest was immediately piqued by both the caliber and the particular sixgun. Jim told me he had totally tuned the action and did a trigger job, however, the customer said he wanted to sell it because it wouldn’t shoot. Jim then mentioned the $600 price and he didn’t have to go any further as I said immediately, “I’ll take it!” I didn’t take any convincing. Any Colt New Frontier — especially one chambered in .44 Special at this price — was not to be allowed to slip by because I firmly believe the right handloads can solve most problems. Not all, mind you, but most.

After I said I’d buy it, Jim explained what the problems were — his customer had complained the gun shot (1) too low and (2) not very well. I took this as a challenge.

When the gun arrived, one look told me what the problem was. The rear sight was raised very high, which told me the previous owner had been using lighter weight bullets — probably 200 grain. This also indicated he’d been using bullets of the wrong diameter. I surmised his loads were handloads with .44-40 bullets sized to .427. I used plug gauges to measure the chamber throats and found them to be a uniform .433, so I loaded up some .431 diameter bullets, screwed the rear sight all the way down and was rewarded with a most accurate shooting sixgun. All it took was the right bullets.

The Right Load

Several years ago I had a 2nd Generation Colt New Frontier that had started life chambered in .357 Magnum. I came up with a 4-3/4″ .45 Colt barrel and had the original cylinder re-chambered tightly to .45 Colt. Everything was right but it would not shoot to my satisfaction so I tried several handload combinations without much success.

Finally, however, I hit on the right one. This little .45 Colt would shoot one-hole groups at 25 yards using the Lyman #454424 Keith bullet over 20.0 grains of H4227. My problem was solved simply by handloading. Another time a fellow wanted to meet with me as he had three S&W .44 Magnums in three different barrel lengths that he said wouldn’t shoot. It didn’t take me long to figure out his handloads were the problem and I was able to point him in the right direction.

Mountain Gun Mystery

Recently I ran into another interesting problem. I have a pair of virtually identical pre-lock S&W .45 Colt 4″ stainless Mountain Guns. Both were fitted with Skeeter Skelton Stocks by BluMagnum — one Cocobolo with a lot of grain and the other plain dark walnut. I shot the Cocobolo gun first and was rewarded with some very excellent groups, however, when I shot the walnut gun, my friend Denis asked if I was shooting .45 Colt loads or .410s! The groups were 4″ and larger.

The Search Begins

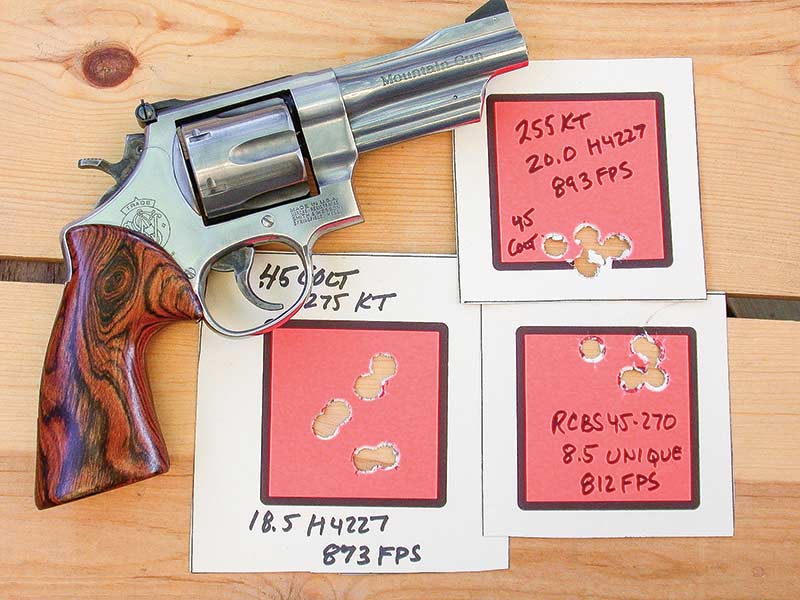

I measured chamber throats on both guns and found them to be a uniform .451, so I figured just trying different loads would solve the problem. Several loads were assembled using bullets from .451 up to .454.

Using the RCBS #45-255 KT sized to .454 over 6.0 grains of Red Dot (and also 6.0 grains of Clays) saw the Cocobolo .45 averaged well under 1-1/2″ while the walnut gun came in over 3″.

An assortment of bullets sized to .451, including the RCBS #45-270 and the Lyman #454424 over 6.0 grains of Red Dot and 6.0 grains of Clays shot even better in the Cocobolo .45 — groups averaging just under 1″. The walnut-stocked .45 remained a lost cause. The Cocobolo Colt Mountain Gun shot everything well and the walnut-gripped .45 continued to shoot poorly. Handloading didn’t solve the problem — so now what?

Forcing Cone, Muzzle Crown?

Friend Denis happened to have the tools needed to re-cut the forcing cone, so it’s the first thing we tried. I really thought this would solve the problem. It didn’t! Now what? Looking at the muzzle under magnification, it appeared there were some very tiny nicks. I didn’t see how this could be a problem but it was something we could try to fix by re-cutting the crown. My local gunsmith at Buckhorn Gun re-cut the muzzle crown. Now I was sure this would be the answer. After all, we now had a custom forcing cone and a custom muzzle crown. It would have to shoot — but it didn’t! Now what?

A Little Factory Help

The next thought was there was something wrong with the barrel. As several of us looked as best we could, it appeared there was something in the bore, just behind the front sight. It appeared to be about a quarter circle on the right side and an even smaller mark on the left side. These were not readily apparent but shouldn’t have been there. So Buckhorn called S&W to explain the problem and they were told to send it back to the factory. So off it went.

After a couple weeks they called back to say they did not have any of the slim “pencil-style” stainless barrels available, but they did have a 4″ heavy under-lug barrel they could install and they gave the folks at Buckhorn the price. Had this been a factory defect they would’ve probably fixed it for nothing. I had purchased this gun at Buckhorn so the owner offered to refund my money. I said I would rather just get it fixed so he agreed to go 50-50 on the barrel price, which I thought was very fair.

The turnaround time was even faster than S&W had promised and they not only installed the new barrel but also a new set of S&W wood target stocks. These are very good looking and quite comfortable — the best to come from Smith & Wesson since they dropped the Diamond Coke Bottle grips 50 years ago.

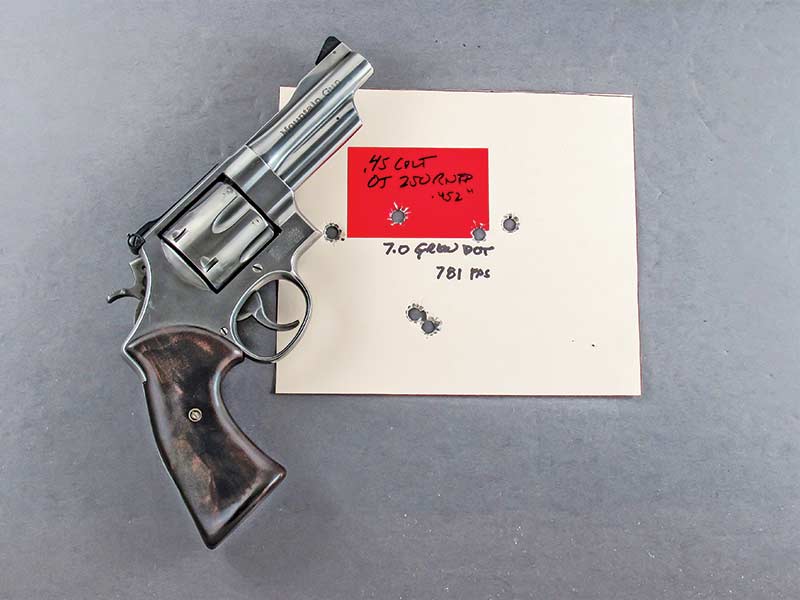

My two .45 stainless steel 4″ S&W sixguns are no longer a matched pair but with the new barrel, groups are even tighter from the full-lug gun than the Cocobolo. My first two groups out of the now heavy barreled .45 gave me groups of 5/8 and 7/8″ for 5 shots at 20 yards. The same load consisting of the Oregon Trail 250-gr. RNFP over 7.0 grains of Green Dot had given 3-1/2″ groups with the old barrel. Success!

A Bulging Culprit

Now this gun has been fixed and shoots well it raises a question — what happened to this barrel to cause this problem? Obviously, the former owner had done something to mess up the barrel which we now know had a bulge. He probably stuck a bullet in the barrel and then sent another one behind it. Denis — who has sensitive fingers — could feel the bulge on the outside of the original returned barrel once he knew what he was looking for.

All of this raises an ethics question. If I have a gun that doesn’t shoot, I am not going to try to pawn it off on someone else. Whoever previously owned this gun sold it to Buckhorn without telling them of the problem.

The gun looks fine, has a smooth action and locks up tight, so the boys at Buckhorn would have no reason to look for a problem. I found the problem by shooting, shooting, and more shooting. Normally I’ve found shooters are way above average when it comes to ethics. This particular shooter was — apparently — an exception.