A Jump Ahead

Germany’s Revolutionary Select-Fire FG42 Rifle

Should’ve Electrified Post-War Arms Development.

But Didn’t SMG Faithfully Reproduces This Strange,

Landmark Rifle Fame Passed By

On appearance alone, the FG42 belongs atop the list of “unique and unforgettable” arms. Once you handle one, you’ll never forget it either—even just the semi-auto version from SMG Guns of Decatur, Texas. Firing a full-auto original must truly be the pinnacle of shooting fun.

Originally designed in 1942 by Rheinmettal as a select-fire, gas-operated battle rifle in Germany’s standard 7.92x57mm infantry cartridge, too few FG42’s saw battle to make a difference, and the original is a top-tier WWII collectible. SMG’s semi-auto recreation lets us experience this unique rifle for a fraction of the cost of the few surviving Class III originals.

Rather than stamped-and-welded sheet metal, the SMG receiver is machined from 4140 steel, and its bolt from 9310, a steel known for its core hardness and high fatigue resistance. Both are heat-treated. The machined trigger housing sports faux weld lines in homage to its stamped-and-welded forebear. The Green Mountain barrel is 500mm long (19.65 inches), chambered in 7.92×57 (also called 8mm Mauser and 8×57) or .308 Win.

The German field manual lists the last FG42 (reproduced by SMG) as weighing 10 pounds, 14 ounces. The SMG rifle weighs 11 pounds, 13 ounces. Add a 1-pound, 14-ounce loaded magazine, an optic, and weight is just over 15 pounds. Even so, it doesn’t feel heavy in the conventional sense—although after a few sessions with the FG, an M1 Garand felt light by comparison!

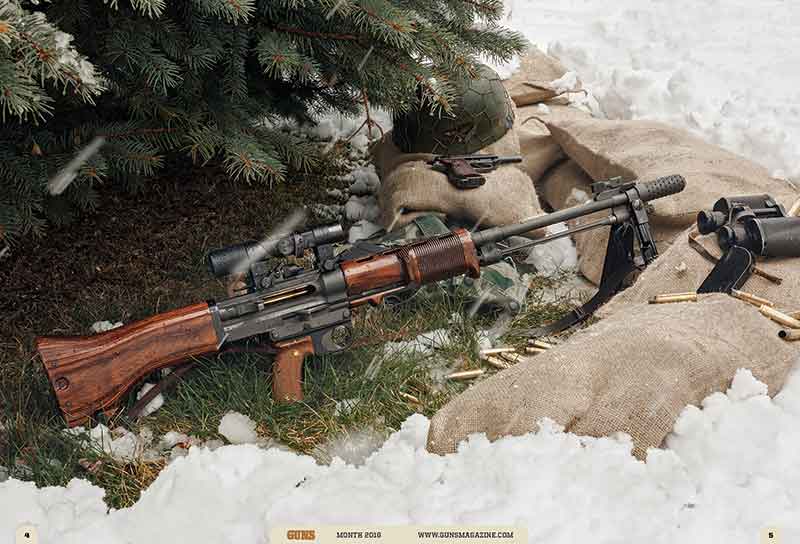

Fallschirmjäger were issued some unique gear including a long knee-length jump smock here in Splinter-B camo,

a sturdy “mushroom cap” helmet covered in chicken wire, stick grenades, often a binocular and an “around the

neck bandolier” holding eight 20-round magazines (loops on the back secured the bandolier to the belt) for a

15+ pound combat load of ammo. A Luger 9mm pistol was standard issue, too.

Otherworldly Aesthetics

The FG42’s handling qualities are as unusual as its looks. Shorter overall than a Model 94 Winchester carbine, the balance point at the center is cluttered by the charging lever and raised hand protection on the forearm. There is no way to carry it comfortably in your right hand. But left hand carry is comfortable—and the magazine isn’t in the way (although you can feel a full mag hanging out there). Slung, the loaded weight is obvious due to the slender 7/8-inch leather sling—a contraption in itself with the strange carabiner front and boxy, detachable rear swivel. It carries well on the right shoulder with the magazine in muzzle up or down, but the charging handle and case deflector dig into your side slung on the left—just another of many unusual asymmetries.

An oft-heard complaint is the heavy side-feed magazine unbalances your aim, but that’s a little too simplistic. The FG42 mounts and holds rock-steady due to the shape of the forearm and the pistol grip when you’re aiming it like the 13-pound full-power rifle it is. Relax your hands and the gun immediately lists to port, so fatigue or laziness are factors—and combine to adversely affect accuracy offhand or from the bench.

You feel the “tilt” when firing. Then, “portside tilt” is a side effect of the bolt rotating left to unlock. The torque is amplified with a full magazine. But maintain a firm, consistent hold, and the gun rights itself.

Magazine Solution

Rather than fabricating magazines, SMG uses surplus 8mm magazines from the Czech BRNO-designed ZB26/30 LMG (the original 8mm version of Britain’s BREN gun). SMG provides a pair of magazines serial numbered to the gun, and I purchased several more from Sarco and one with a Waffenamt from IMA-USA. If you’re worried about finite supply, SMG offers the FG42 in .308 Winchester using M1A magazines. (The .308 solves the nagging problem of malfunctions induced by surplus mags suffering from spring fatigue, too.)

The magazine catch also holds the twin dustcovers closed. The magazine follower holds open the bolt on the last shot, and there is no other bolt hold-open device. It’s best to restrain the charging handle before removing the magazine. This makes removing the mag easier and stops the heavy bolt from slamming home.

These folding sights are an old-school take on today’s AR Back Up Iron

Sight concept. The front sight sits in a protected ring and folds back.

The bayonet is numbered to the gun and is a reproduction of the FG42

bayonet, not a shortened MAS 36 usually found on SMG repros. The

bipod is a weak point. To pare weight, it is flimsy stamped metal,

doesn’t lock open and may collapse if you lean into the gun prone.

Operation Armstrong

Cocking effort is easy once the bolt is cammed out of battery, but you need some muscle to jolt the bolt. Cocking leverage is poor as you can only get two fingers on the short, narrow, curved charging lever. Since it reciprocates on firing, a larger lever isn’t the answer. I made a wooden “cheater bar” to ease charging.

The protrusions on the odd-looking handguard keep your offhand positioned safely away from the reciprocating lever and excess hot gases venting in front of the fore-end.

The rifle can’t be charged unless the safety is in the “Fire” position. To apply the safety, swing the lever 90 degrees up and to the rear. It isn’t very natural, but it is completely natural for the firing hand to sweep the lever down to “Fire.”

Fallschirmjäger were issued some unique gear including a long knee-length

jump smock here in Splinter-B camo. Clockwise from the stick grenades

(note the grenade’s cap unscrews so the fuse lanyard can be pulled) are

the FG42’s “around the neck bandolier” holding eight 20-round magazines

(loops on the back secured the bandolier to the belt) for a 15+ pound combat

load of ammo, the ZF4 scope atop its box worn on the waistbelt or slung,

“mushroom cap” helmet with chicken wire to hole twigs and camo what

not, 6X binocular, and generally a Luger 9mm in a holster was standard issue,

although by the end of the war any handgun was used. The belt had a blackened

metal belt buckle. The all-cotton jump smock was white on the inside and could

double as snow camo reversed. The sleeves had internal wrist closures, the

armpits were vented and the lower part snapped around the pants.

Trigger Qualities

A mechanism born of a machine gun begets a heavy trigger pull. Although SMG modified the trigger to give a better pull, there’s just no way to make it lighter. The heavy gas piston’s forward movement is stopped by the sear of the trigger mechanism, and these parts are sturdily built. The centerline of the firing pin is about 1-1/4 inches above the sear. The gas piston holds the firing pin on a yoke within the rotating bolt. This yoke also acts as the bolt cam to unlock and rotate the bolt.

The entire bolt and gas piston assembly—weighing 1 pound, 10.9 ounces—is in movement during the loading cycle. The bolt rotates closed and locked assisted by an internal spring behind the firing pin. The gas piston (holding the firing pin) is held back about 5/8-inch by the trigger mechanism. When the trigger breaks, the gas piston assembly flies forward powered by the recoil spring with an assist from the firing pin/bolt spring. It doesn’t travel far, but in essence, it’s as if the firing pin weighs 1 pound, 2.5 ounces (the weight of the firing pin and gas piston—the bolt itself is closed and locked). So 1/10th of the rifle’s weight moves violently in discharging the rifle. You can really feel this huge mass fly in dry fire. But use snap caps—A-Zoom makes ’em. The FG should never be dry fired.

The trigger has a little bit of grittiness before it turns into a long, heavy, smooth pull which lets go without warning. Combine this with the shock of the piston flying forward and accurate shooting requires solid technique. Hold the gun firmly with both hands, get into a rhythm, and the gun delivers fine groups. Poor technique and groups grow.

After shooting more than 300 rounds, I measured the trigger pull at a whopping 10 pounds, although I guessed it to be around 6 or 7. (There’s method to my madness in that I’ll always remember the pull as lighter than it measures. Pavlovian, but effective.)

The rifle comes with fully adjustable front and rear sights. Progenitor of modern “back up iron sights,” both fold down per the original, and SMG improved the rear by adding optional windage. The elevation adjusts by pressing down on the aperture and turning the drum. When the aperture is released, it pops into place at the selected range indicated by a number etched on the drum. A screwdriver is necessary to adjust the windage. There is no windage scale, but the roll pin holding the windage screw on the left side can be used as an ersatz increment. The hooded front gives a crisp sight picture. It must be disassembled to fine-tune the elevation, and has small parts, so be aware.

The ZF4 scope bears Meopta’s (then Opticotechna GmbH, Werk Prerau)

WWII code “dow” to the right of the turret. The scope should have an “L”

for Luftwaffe centered on the scope body below the turret. The magazine

well is protected by twin spring-loaded doors held closed by the mag catch.

The safety, shown in “fire” position swings back and up 45 degrees to “safe.”

The heavily constructed ZB26/30 magazines hold the bolt open on the last

shot via two large lugs on the back of the follower.

Optic

Two quick-detachable scope mounts were created for this model originally. Rheinmetall’s racy 1-piece mount is called the “swallowtail.” Contrary to specification, primary maker Krieghoff invented 2-piece mounts only working on their rifles. Of today’s repros, the 1-piece mount only works with SMG’s standard fixed-windage rear sight, and the 2-piece rings with either rear sight. Both mounts are reproduced by machinist Estes Adams. On the 2-piece rings, the key is to lock down the rear lever first, then the front. The system holds zero well.

The standard scope for the late-model FG42 rifles is the ZF4 3.5X (commonly seen atop the Walther K43 semi-auto rifle). Numrich Gun Parts has the remainder of 1,000 ZF4 scopes made by Meopta of Czechoslovakia for a German distributor in 2009, and I chose one of these. Meopta is the descendent of optics maker Opticotechna GmbH, Werk Prerau, and this scope wears their WWII German code “dow.” Numrich also imports a Chinese repro ZF4 scope with primary scope maker Voigtländer’s “ddx” code.

Zeroing the scope was frustrating due to the primitive 75-year-old technology. Elevation is adjusted mechanically while windage optically. Remove the top turret cap and a plate held by three tiny screws to reveal the internal windage screw. When turning this screw left or right, a cam tilts the internal lens, and the crosshair stays centered. Upon passing either end of the adjusting cam’s travel, the lens recenters itself rather than just coming to a stop—only obvious when using a boresight (and will drive you batty if you don’t). Once set, the windage can be fine-tuned by turning the top turret under the protective cap, but the adjustment is limited to +/-5 MOA and “clicks” are approximately 1 MOA.

The elevation adjustment is also under a plate held by three tiny screws and allows you to zero the reticle for 100m so the turret setting stays on “1.” Turning the turret adjusts elevation in 50m clicks up to 800m. The crosshair visibly moves up or down in the field of view during adjustment. Since there are no reference “clicks” when turning these internal windage and elevation adjustments, a boresight is crucial. I suspect German factory armorers had a variety of ring parts they could mix and match to align the scope, as many were numbered to the gun.

When you have one scope, one mount, and one gun, you (or your gunsmith) have to make them work, so be advised. The scope’s adjustments are very limited, and I wrote about shimming the scope in the August ’16 issue. Meopta and ringmaker Adams have made faithful reproductions, warts and all.

First Shots

When first shooting, turn the 3-position gas valve to low, and fire one shot. If the bolt locks open on the mag follower, you’re good to load. If not, open the gas valve one turn. Watch the ejection pattern over the first several hundred rounds as the gun breaks in. Turn the gas valve down if the brass starts showing bad dents, or rounds get crushed feeding.

As to recoil, the FG42 shoots softly. Recoil is mitigated by gun weight, buttstock buffer and muzzlebrake. Muzzle climb is negligible thanks to the brake and the straight axis from bore-to-shoulder. Normally a gun without some muzzle heaviness will aim a bit squirrelly, but the FG42 holds rock steady.

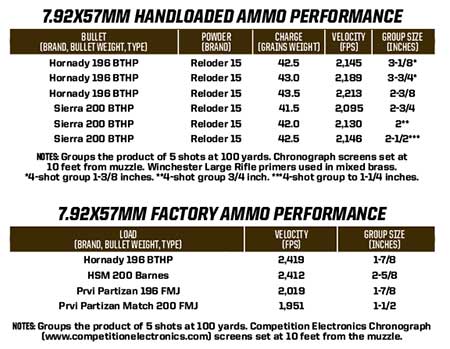

Accuracy

The ammo mix included Hornady Vintage Match (a series of loads revitalizing many classic military rifles), a Hunting Shack hunting load with Barnes bullet, Prvi Partizan FMJ and Prvi Match. All bullets weigh between 196 and 200 grains. The Prvi Match load gave a best group of 1-1/2 inches at 100 yards. My best 5-shot group with the standard Prvi FMJ was 1-7/8 inches.

Hornady delivered several 5-shot groups of 1-7/8 inches with both irons and optic. Both Hornady and HSM ammo shot 9 inches high, however. The HSM, topped with a 200-grain Barnes bullet, delivered a 2-1/2-inch group, with 3 of the 5 shots inside an inch. The point-of-impact difference isn’t surprising since both “H” loads are 400 fps faster than either “P” load (both of which shot 4 inches over point-of-aim). All in all, the gun will group if the loose nut behind the trigger stays tight! Take a cavalier attitude to shooting and groups grow to 3-4 inch range.

A flyer or did Jeff honk one shot? Shooting Sierra 200-grain MatchKings,

four shots are in 3/4 inch with the 5th pulling out the group to 2 inches.

With a 10-pound trigger and the 1-pound gas piston flying prior to

discharge, it’s hard to tell. (If you’re careful, you can peel Shoot-N-C

targets off the paper and save them on the original backing.)

Handloads

SMG voids the warranty if reloads or surplus ammo is used. Since the 7.92×57 has been loaded by so many countries to widely varying pressures, some are far too hot for all but a solid bolt action. (See the sidebar on how the Germans mitigated this problem.) But handloading offers solid benefits. I failed correcting the optic with additional shims for elevation in addition to windage, yet achieved the elevation correction through handloading. Another goal was to match the load to the gas system so ejection was neither sluggish or too abrupt. The “just right” spot would eject the case about a yard forward with minimal case dents.

Since my brass was mixed Hornady and Prvi, I checked the internal capacity to see if they would need segregation. Filled with water, the Hornady and Prvi cases weighed within 2/10 of a grain, so I felt I could mix them safely. Before primers would seat in the Prvi cases, however, the primer pocket needed a couple of turns of the case neck uniformer. In another odd turn, the Prvi cases were already near maximum case length, and needed trimming after one reloading. The Hornady cases have yet to require trimming after three loadings.

I didn’t work up loads in the conventional way, since the starting load probably wouldn’t cycle the action, and the FG mangles brass badly if the load is too light. I planned to work on a load cycling the action well first, then fine tune it for accuracy.

So I chose a load 10 percent below maximum as my starting load. Alliant Reloder 15 is one of the powders with a medium burning rate I felt would work well in a gas gun (it was on the shelf at the gun store and I was allowed to buy more than one).

Sized in RCBS dies, my first loads with Hornady and Sierra bullets over Alliant Rl-15 ran about 2,200 fps. With the gas valve on “low” the cases got crushed on ejection, and on “medium” the action cycled too abruptly.

My reloading technique may sound weird, but I was loading to the gas system first. So, one grain down, loads cycled sluggishly on the medium gas valve setting, gave good accuracy and shot to point-of-aim. Going up 1/2 grain, the gun cycled smoothly and accuracy was better. The brass came out with minimal body dents in a nice puddle 1-yard away, so the rifle ran happier. Bullets impacted just a couple of inches over the front sight, and I’m happier. Shooting a 4-shot 3/4-inch group with the Sierra bullet was pretty exciting, even if the 5th shot pulled out the group to 2 inches. Going up another 1/2 grain and the group began to grow again, so my load with the Sierra bullet remains at 42.0 grains.

The Hornady bullet’s groups were shrinking as the charge went up, but I went no further because the next couple of increments would likely require the gas valve turned down a notch, and the bullet’s impact would likely rise. With this story’s deadline looming, winter around the corner, and other projects to finish, I had to shelve fine tuning the Hornady load until next spring.

On the fun front, I am able to regularly hit the Washoe County Range’s 14×14-inch square gong at 300 yards 6 to 7 times out of 10 with iron sights. When using the optic, the rifle shoots softly enough it comes out of recoil in time to see the bullet strike at 300. I seem to achieve the same hit probability using irons or optic, oddly enough.

The Germans valued optics and the FG42 spec called for such capability

from the start. This Meopta-made 3.5X ZF4 is fitted in repro quick-detach

rings and carried in a wooden box (bottom left). Plans in 1944 called for

1 in 10 rifles to be fitted with an optic. A sunshade (atop the box) was

provided and snapped on to the front, and a rubber eyepiece went over the

ocular. A binocular was an important accessory to marksmen and this “bmk”

6x30 with a ranging graticule is typical. The “bmk” code stands for Srb &

Stys, Fabrik praeziser Messinstrumente, Prag. The sling’s code “ewx” is

for Franz u. Karl Voegels, Lederwarenfabrik, Cologne.

Drawbacks

Like the original, accuracy is not this rifle’s signature attribute. Since it is sturdily built with a high-quality barrel, decent accuracy can be coaxed from it.

It’s heavy and needs a lot of muscle to operate. The action is “fussy” and its cycling tantrums destroy ammo or brass if not adjusted correctly.

Safety requires extra attention. The rifle can’t be charged with the safety “on.” The bolt has no hold open and it is difficult to visually inspect the chamber from either side. The magazine holds the bolt open, and common range rules say “action open and mag removed during cease fire.” I use a dowel through the ejection port to show “clear.” The bipod is flimsy, doesn’t lock open and prone to spontaneous folding if you lean into the gun.

The price is high (so were originals). The US Aberdeen Proving Ground report from 1944 concludes, “The FG42 has been produced with apparently little thought as to the difficulty and cost involved in manufacture. The cost of a weapon of this kind manufactured in the United States would be excessive.” (1)

This 100-yard group of 4-1/2 x 4-1/2 inches is one 20-round magazine fired at 1 shot per second. Note the

fore-end chip. During break in, it appears a spent case not fully ejected was accelerated by the charging

handle and the mouth of the case acted like a chisel. Luck was with Jeff as the Washoe County Rangemaster

allowed him to search his former shooting position a week later. Jeff found the chip intact and glued it back.

Prvi Partizan Match (above) delivered the best 5-shot, 100-yard group of 1-1/2 inches. Trigger management

and consistent sight alignment deliver rewards. After a sight correction, these 3 shots, are centered and all

6 in 3 inches at 100 yards (below). Why 6 shots? Jeff had 6 rounds left after monkeying with the sights.

Groups like this are typical when your shooting technique lapses.

What Might Have Been

The FG42 solved the transition from bolt-action to semi-auto to select-fire battle rifle, yet a rifle evolution was already passing by. The German Army’s StG44 revolutionized post-war military small arms. Unappreciated in the West, the StG44 and its pioneering intermediate cartridge was enthusiastically embraced by our Communist foes evolving into the 7.62x39mm AK-47.

The fielding of a successor select-fire, major-caliber battle rifle in the postwar West failed when designers ignored the FG42’s basic strong points as identified in the Aberdeen Proving Ground report. Warfighters would have been ably served by a perfected optics-ready, select-fire battle rifle as controllable and light recoiling as the FG42—working proof the concept was feasible. We’d probably still be using it. (Stoner devotees would say one was created, but that’s another story!)

The SMG FG42 is as temperamental and expensive as a German sports car! As long as you understand and are willing to work with what is essentially a high-quality reproduction of nascent WWII technology—including the optic and mount—the SMG FG42 provides today’s firearm student a time capsule back to a unique, little-known battle rifle.

And, after firing more than 1,000 rounds, I guarantee you it’s really a hoot to shoot!

Gas pains! Never underestimate the power the FG’s 1 pound, 10.9-ounce bolt and gas piston mechanism transmits to a case

during cycling! Too little gas (left) and the bolt doesn’t open far enough to fully eject, smashing the cases into the receiver

upon its return. Just right (middle left) and ammo feeds flawlessly, ejecting about a yard forward with none or minor dents.

A little too much gas and cases get slapped hard by the case deflector (middle right) and fly about a foot or more past

the 1-yard mark. Too much gas causes the bolt to reciprocate too quickly (right) and can mangle the round trying to feed.

Run the valve/ammo combination right and the FG purrs like a contented cat. Set wrong, it turns into a brass-eating lion.

SMG’s optional fully adjustable aperture sight is far more field-usable than today’s BUIS. Although there is no scale,

the roll pin through the retaining disc is useful keeping track adjusting windage. Different colored discs in amber,

gray or green to improve contrast were stored in the scope box’s slot (seen just behind the raised peep).

Further Readin

Death From Above, by Thomas B. Dugelby and R. Blake Stevens, ©2007, 228 pages, 278 illustrations, hardcover, $59.95, ISBN 0-88935-429-4, Collector Grade Publications, P.O. Box 1046, Corbourg, Ontario, Canada K9A 4W5, (905) 342-3434, www.collectorgrade.com

FG42

Maker: SMG Guns

1033 CR 4380,

Decatur TX 76234

www.smgguns.com

Action type: Rotating bolt, semi-auto

Caliber: 7.92×57 (tested), .308

Capacity: 20

Barrel length: 19.65 inches

Overall length: 38-1/4 inches

Weight Unloaded: 11 pounds, 13 ounces

Weight loaded with scope: 15 pounds, 3 ounces

Finish: Parkerized and blue

Sights: Fully adjustable folding front and rear

Stock: Wood laminate

Price: $4,995 (bayonet extra)

ZF4 dow

Maker (optic): Meopta

50 Davids Drive

Hauppauge, NY 11788

(631) 436-5900

www.meoptasportsoptics.com

Importer: Numrich Gun Parts

226 Williams Lane

West Hurley, NY 12491

(845) 679-4867

www.gunpartscorp.com

Maker (mounts): Estes Adams

www.gunbroker.com

(search: FG42, click on: “FG42 type II replacement parts”)

Magnification: 3.5X

Objective Diameter: 25mm

Eye Relief: 4 inches

Click Value: Elevation: 50m intervals 100m-800m

Windage: 1 MOA at 100 yards (approx)

Tube Diameter: 30mm

Weight (with rings): 18.6 ounces

Overall Length: 6 inches

Reticles: Post/Crosswire

Price: $499 (scope & accessories), $415 (rings)

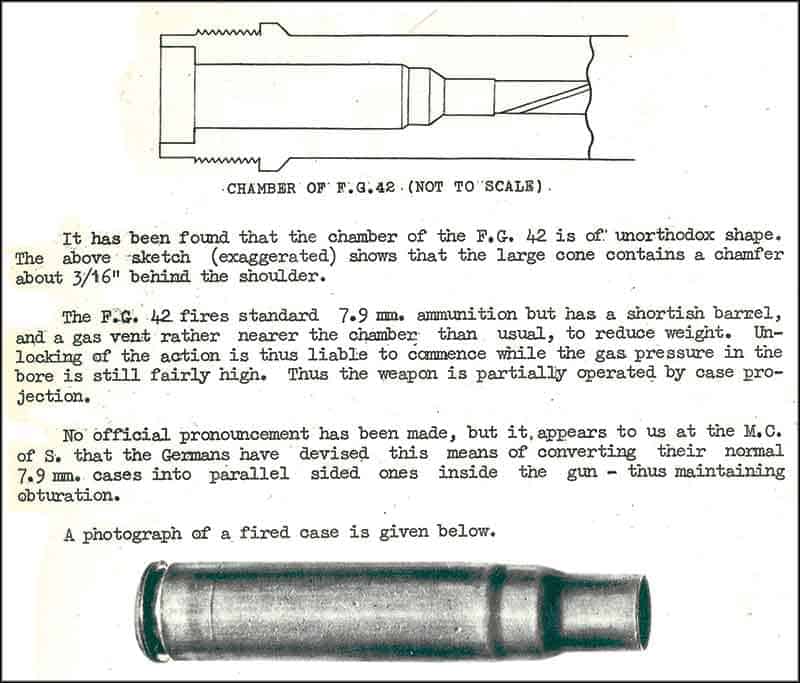

The signature achievement ensuring the FG42 could run widely variable ammunition is its unusual chamber shown in

The Small Arms Circular Vol. 1, No. 2 produced by the British Army Military College of Science in March 1945. Page 15 (shown)

attempts to explain this most interesting and little-known concept. Note the fired case. Handloaders should give thanks

SMG didn’t use a chamber like this! Photo courtesy R. Blake Stevens, Collector Grade Publications

Crucible Of Genius

The full power, 7.92x57mm select-fire FG42 was born of tactical failure. German Fallschirmjäger (paratroopers under the command of Hermann Göring and the Luftwaffe) dropped into the fight armed with pistols and submachine guns. Their rifles and belt-fed light machineguns dropped separately in canisters—fine for surprise attacks, but in the battle for Crete, the British and Greeks were waiting. Unable to return fire until their canisters were opened, the paras took heavy casualties.

Hitler then banned future airdrops, but the Luftwaffe forged ahead issuing Technical Demands for the Development of a Paratroop Rifle, Specification LC-6. The new “theory” declared Fallschirmjäger would defend themselves from the air with a select-fire rifle and effectively engage enemy troops from the get-go with precision levels ranging from an optic-sighted rifle to light machinegun. It was to weigh 10 pounds, thus a little heavier than the K98k and considerably less than the 25+ pounds of the MG34 LMG.

The concept of an intrepid Fallschirmjäger defending himself from the air is a bit far fetched. Not only is there enough to do during a drop without deploying a weapon, the weight of the arm and ammo is substantial. The weight of the rifle is 11-1/2 pounds loaded and the combat load of magazines—gun and ammo are both theoretically around the trooper’s neck—is 15+ pounds. I wonder how survivable such an arrangement would prove during an actual drop?

The concept of a full-power 10-pound select-fire rifle was considered impossible and declined by the major small-arms makers already at capacity production. Anyway, the army was quietly developing the StG44 in 7.92×33 and didn’t want scarce resources diverted.

Armsmakers Rheinmetall (Göring sat on its board of directors) and Krieghoff (whose design was rejected) took on the project. Rheinmetall engineer Louis Stange delivered a working prototype almost fully meeting the theorist’s dream gun in astoundingly short order—just three months.

Even skeptical army ordnance officers were impressed during the “shoot to destruction” test. Göring presented Hitler with one of the first 50 rifles and arranged a demonstration in December 1942. Hitler, who had earlier nixed the rifle, reversed himself and declared the new rifle the “Fallschirmjägergewehr Zweiundvierzig.” He opined it would become the standard infantry rifle after the war.

Unique Chamber

A weight of 10 pounds was a key parameter, and to pare weight, Stange moved the gas system closer to the chamber and machined away every extra ounce of steel, leaving little margin for safety. If chamber pressures were too high the rifle could unlock too early endangering the shooter and gun. Knowing ammo pressures were highly variable due to the vast number of manufacturers, Stange’s inventive double-neck chamber allowed the body of the case to form into a nearly straight cylinder. If the action unlocked too early, this double seal protected the shooter (and gun) from escaping high-pressure gas. Variations on this theme have been used to control unlocking since.

First combat use occurred in May of 1943 and German parachutists would use a few FG42’s in many actions. Describing the provenance of two featured in the book Death From Above, one early model was taken off a dead para at the Battle of the Bulge, and a late model (as SMG reproduces) was found after the Battle of Monte Cassino in Italy.

Allied bombing led to a scarcity of materials. While visually there are two basic models, between shortages and improvements enough design changes occurred that seven variants have been identified in Dugelby and Stevens’ book (the Germans ignored model classification entirely).

In January 1944 the FG42 was formally adopted. An optimistic order for 120,000 rifles (delivered at 10,000 per month) was given to Krieghoff (Rheinmetall didn’t have sufficient capacity). Scope maker Voigtländer was to provide 12,000 ZF4 scopes. The order included 1,000 armorer’s chests and 2 to 3 million magazines. But it was too late. Only 6,000 to 7,000 of all models were made before hostilities ceased.

Post War Test

Aberdeen Proving Ground held a shoot-to-destruction test noting salient capabilities of firing on full automatic from an open bolt, and semi-auto from a closed bolt; an effective muzzlebrake and a buffer in the buttstock; low bore center so recoil is directly inline with the shoulder and provision for an optical sight. While the concept of such an arm excited Western militaries, these recommendations were mostly ignored in the quest. The post-war full-power, select-fire rifle ultimately lead to our adoption of the 7.62×51 M14 and our allies the FN/FAL.

It’s no surprise the concept failed without keeping the FG’s key virtues intact. Two other points ignored were the side magazine to ensure the soldier stayed as low to the ground as possible, and the folding bipod. The FAL came close, but missed the mark. The M14 missed it almost entirely. Later, after these arms were fielded, designers then tried to shoehorn many of these lost features, all of which ended in failure for the most part. The FG’s design values weren’t completely lost on arms designers, as elements of it surface in our M60 machinegun.

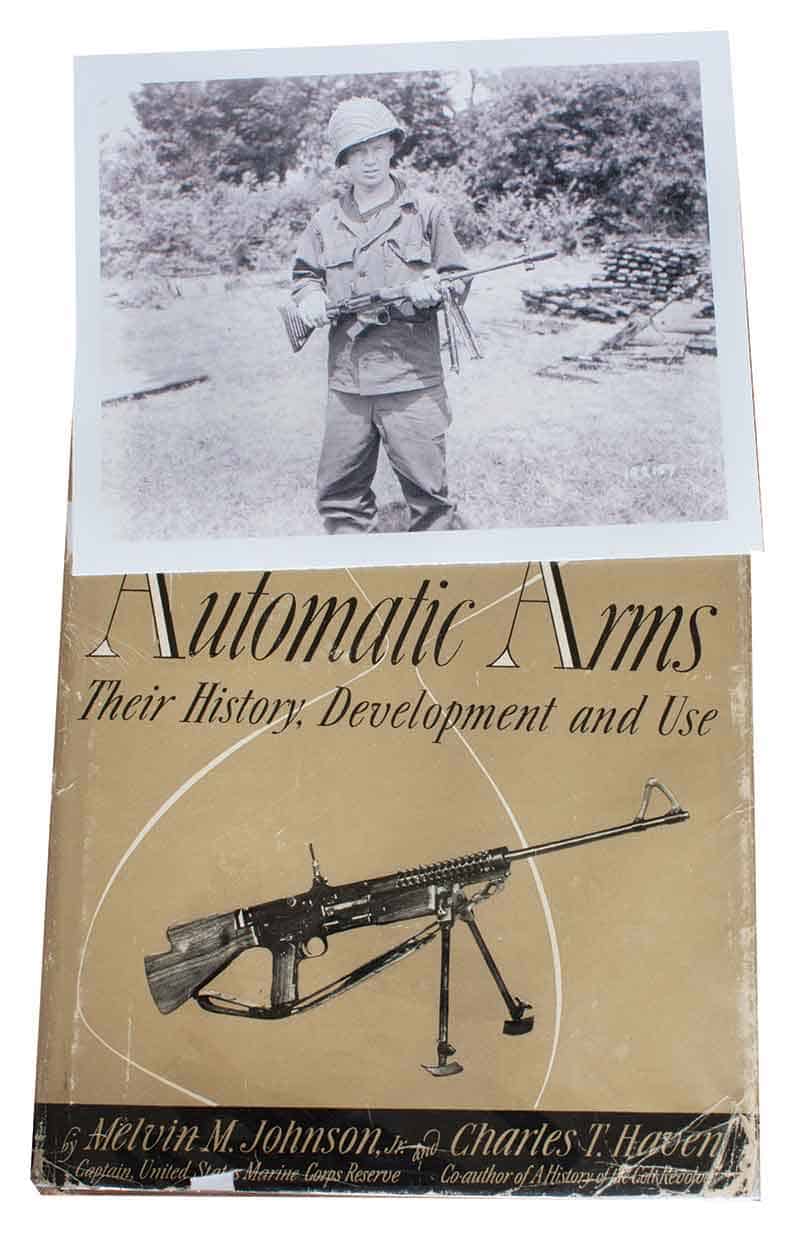

A US Army soldier near St. Lô, France in 1944 holds an early (and forlorn-looking) FG42 sans bayonet with mid-section

bipod similar to the Johnson LMG’s. German testing concluded mounting the bipod near the muzzle improved accuracy,

and the rakish pistol grip, designed for use from the air, was later replaced with a more conventional one. The photo

is atop the book by Melvin Johnson in which his LMG illustrated on the cover is detailed.

Spies Or Smarts?

Similarities between the M1941 Johnson Light Machine Gun and the FG42 are remarkable. While espionage is a romantic notion, Melvin Johnson and Charles Haven’s book Automatic Arms, Their History, Development and Use was published in late 1941 with schematics of many automatic weapons including the Johnson LMG and a description of its design. It could be a case of parallel development or perhaps our soon-to-be foes simply bought the book and Stange found inspiration inside.

Many of the Johnson LMG’s advantages were incorporated into the FG42 prototype, including the side-feed magazine capable of being topped off with stripper clips, a mid-barrel bipod folding forward, a folding rear sight (improved on logically by adding a folding front), straight-line recoil and firing from a closed bolt on semi auto and—most importantly—an open bolt on full auto.

It’s easy to imagine this book landing on Stange’s desk with the LC-6 spec. Even without a translation, a man of Stange’s skills would quickly see the M1941’s advantages. Here was a select-fire LMG at an unheard of light weight of 12+ pounds. One feat thought impossible in the LC-6—the weight-spec—was almost there. After all, all comparable full auto rifle-caliber arms weighed 18 pounds or more.

Did Stange pull ideas from the book? Eugene Stoner, familiar with Johnson’s M1941 LMG during his Marine Corps service, used it as a springboard in developing the ArmaLite AR-10. There’s no evidence Stoner, who served in the Pacific, ever saw an FG42 or the Aberdeen report during development of his rifle, but both Stange and Stoner logically evolved Johnson’s truly “Light” LMG concept into a select-fire battle rifle.

Whatever the case, Stange’s finished prototype was working when it usually takes substantially more time to develop an arm from scratch. Stange also borrowed ideas from many other arms. The heart of the action uses elements of WWI’s American Lewis gun (the earliest version even used the Lewis gun’s spiral spring), and the bayonet is similar to (but not interchangeable with) the French MAS 36. The FG42 was truly a hodgepodge of existing ideas, and one reason Stange was able to complete the prototype so quickly. Whether there is a connection to the Johnson is lost to history and the above mere supposition on my part.

Disassembly

Takedown of the FG42 for routine cleaning is simple and quick. The hard part is cleaning from the breech end due to the depth of the chamber inside the receiver. Use a long 44-inch rod and be prepared to fish out a patch or two from inside the action.

Pull the charging lever back. The charging lever can be removed to the

left at its rearmost travel. A button inside the gas piston tube engages

a recess in the charging lever, trapping it. If the lever will not come out,

tap the back of the receiver bottom with a wood or rubber mallet to

dislodge it. It will not need much force. With the lever out, remove bolt

and gas piston out the back of the receiver. The bolt will rotate and slide forward.

A pin through the rear of the bolt holds the firing pin spring. Remove this pin

by depressing the internal spring with a small screwdriver, and drift out the pin.

The spring and plunger come out the back. The gas-piston and its yoke come

straight down, freeing the firing pin to come out the rear. The bolt is shown with

its parts in order. To make barrel cleaning easier, lift the muzzlebrake latch and

unscrew the muzzle brake.

Gas Valve Disassembly

Alliant Powder

2299 Snake River Avenue

Lewiston, ID 83501

(800) 379-1732

www.alliantpowder.com

Hornady

P.O. Box 1848

Grand Island, NE 68802

(308) 382-1390

www.hornady.com

International Military Antiques, Inc.

P.O. Box 256

Millington, NJ 07946

(908) 903-1200

www.ima-usa.com

Hunting Shack, Inc.

4406 Rathbun Lane

Stevensville, MT 59870

(800) 856-2857

www.hsmammunition.com

A-Zoom (Lyman Products)

475 Smith Street

Middletown, CT 06457

(860) 632-2020

www.lymanproducts.com

Prvi Partizan, TR&Z USA Trading

2499 Main St

Stratford, CT 06615

(203) 375-8544

www.trzusa.com

RCBS

605 Oro Dam Blvd

Oroville, CA 95965

(800) 553-5000

www.rcbs.com

Sarco, Inc.

50 Hilton St

Easton, PA 18042

(610) 250-3960

www.sarcoinc.com

Sierra Bullets

1400 West Henry Street

Sedalia, MO 65301

(888) 223-3006

www.sierrabullets.com

World War Supply

P.O. Box 72

Ada, MI 49301

(616) 682-6039

www.worldwarsupply.com