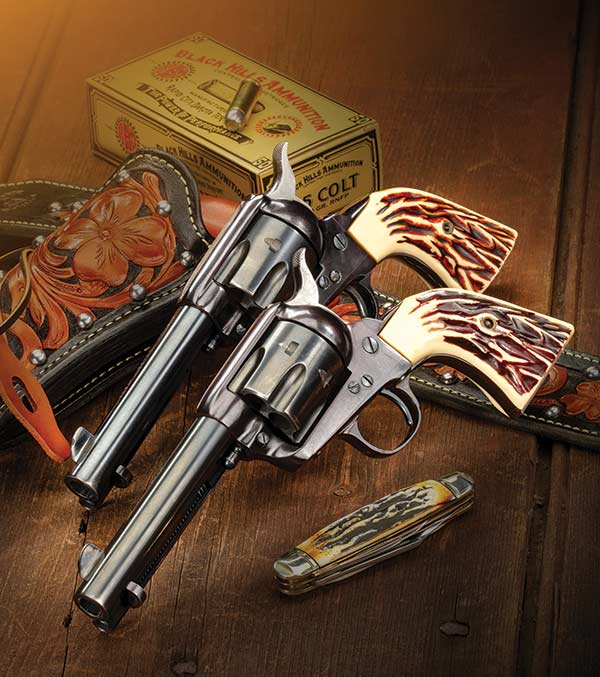

However, this handloader did not realize the insufficient neck tension represented not only a mechanical problem but also a potential hazard. So, he drove the protruding bullets back into the cases, cocked the hammer and pulled the trigger. The cylinder and frame disintegrated. Poof! A very expensive custom revolver sacrificed as a valuable handloading lesson in so many microseconds.

The primer blast moved the bullet into the barrel before propellant ignition occurred, because neck tension was inadequate. Then the compressed chunk of propellant behind the bullet ignited. As the Krupp Commission proved in 1888, ignition of a charge resting entirely at one end of an unfilled chamber always generates a standing pressure wave within the chamber. In this instance, pressure at the peak of this wave progressively increased until it exceeded the strength of the cylinder. For lack of a better term, we erroneously call this process a detonation.

Never assume any die set leaves the case with adequate neck tension. Historically, manufacturers commonly shipped dies with oversized expanders, as in this instance.

Another handloader tested a self-concocted load in his .300 Weatherby Magnum. He believed the relatively mild CCI-BR2 primer might give better accuracy than he had gotten with the recommended, and relatively powerful, Federal 215 in his first version of the load. He tested his BR2 loads when it was 32 degrees F (I happened to be at the range). He was using a hard-to-ignite, single-base propellant. The charge did not come close to filling the case. His was a perfect recipe for a detonation. On his second shot, the charge failed to ignite.

Case dissection showed the primer blast had compressed the charge into the front of the case and fused many granules. Almost certainly, if the propellant mass had subsequently ignited, it would have destroyed the gun through detonation. Follow the recipe and never assume any component substitution is safe.

My testing at the Accurate Arms ballistics laboratory proved even when a detonation is unlikely, primer substitutions often alter pressure widely—and unpredictably. For example, in the .30-06 with a normal charge of A4350 in otherwise identical loads, pressure using various rifle primers varied by 17 percent (54,500 psi to 63,900 psi).

Worse, how primer substitutions will alter pressure is entirely unpredictable. For example, in some handgun loads, use of a standard primer instead of a magnum primer will double pressure. Therefore, when someone tells you they can predict how a primer substitution will alter a load, stop listening: They have just demonstrated they do not know what they are talking about.

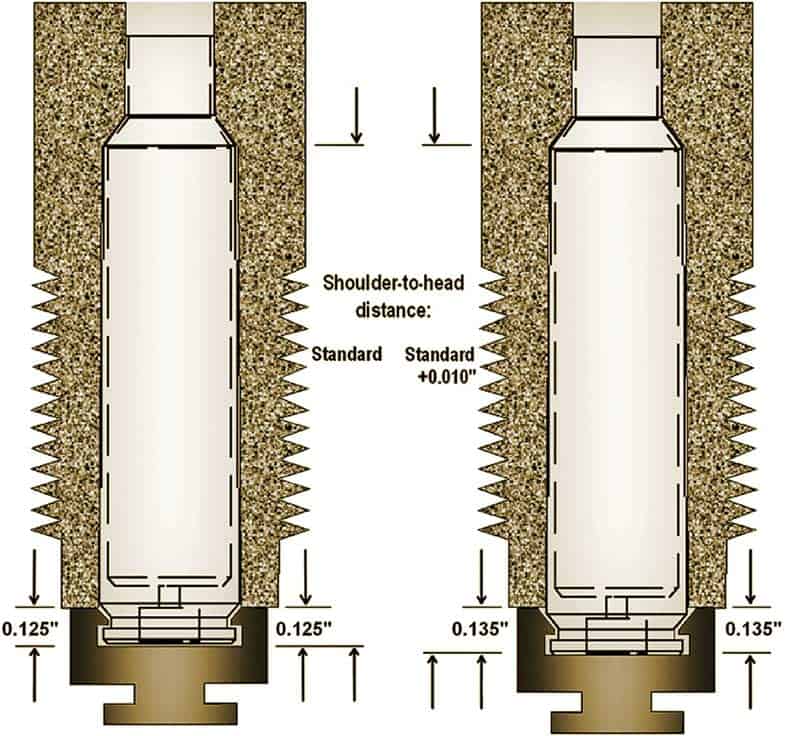

Improper primer seating is the most common primer-related problem in handloads. The face of a properly seated primer always rests noticeably below the head of the case. Inadequately seated primers result in misfires and squibs and can lead to a detonation.

Consider bullet substitutions. Bullets of the same weight and basic type vary both in length and in core and jacket toughness—these variations matter—longer bullets tend to generate more pressure (bullet occupies more of the case), harder bullets tend to generate less pressure (reduced obturation results in reduced bullet-to-bore friction). For example, in standard-length .270 Winchester loads using identical charges of A4350 and the CCI-BR2, pressure with various 150-grain hunting bullets varied by 32 percent (54,700 psi to 72,400 psi). The former would be a very mild .270 load, the latter is in the pressure range for a .270 proof load.

Ballistician Bill Falin did similar tests with the .35 Whelen. The charge of A2015 needed to generate maximum pressure with various 250-grain spitzer bullets varied by 8 grains.

To avoid using the wrong propellant or returning unused propellant to the wrong container, never have more than one propellant type within reach during any loading session. To avoid using the wrong charge:

• Always double-check the scale setting to verify you are using the intended charge (as a nascent handloader, circa 1968, I had to pull bullets from 20 .244 Remington loads after discovering I had the scale set 5 grains off what I intended).

• Always verify you are using the intended data (handloaders have destroyed dozens of .300 Winchester Magnum rifles when they inadvertently used .300 Weatherby Magnum data; any similar mistake can be similarly disastrous).