Stingin' Hot Hornet

Synopsis: Winchester introduced the .22 Winchester Center Fire (WCF) in 1885. Europeans began experimenting with smokeless loads in .22 WCF cases before the First World War. Employees at Frankford Arsenal began such experiments after the war. Winchester introduced such loads, under the .22 Hornet name, in 1930.

Thereafter, the Hornet has held the dual dichotic distinction of being a chambering in which practically every serious rifleman longs to own at least one rifle, while being a good contender for the cartridge using the worst case ever standardized. Despite this limitation, I appreciate what the Hornet can do. Equally, I appreciate the CZ 527 as an ideal Hornet platform. So, I asked myself: “How about a CZ Custom Shop Hornet?”

The .22 K-Hornet, an old pre-WWII wildcat, is superior to the standard Hornet and I can shoot standard Hornet ammunition in a K-Hornet with no loss of accuracy or velocity—enlargement of the cartridge case as the round fires allows that portion of the charge not ignited by the primer to reorient, and, as that happens, more granules ignite sooner, which offsets the increase in chamber volume. Most importantly, in a gun with appropriate striker energy, when loaded using an appropriate (mild) primer, the case shoulder of the K-Hornet will hold headspace. K-Hornet accuracy is usually better, and—with neck sizing—K-Hornet cases last longer.

Besides the standard handloading issues affecting load pressure, the K-Hornet introduces a unique problem. Unlike other wildcat chamberings, no standard K-Hornet design exists. Kilborne, the inventor, made his reamers. When one wore out, he made a new one. No two were closely similar in any dimension; and, he ran those reamers a different distance into each chamber he converted from standard Hornet to K-Hornet, so no two Kilborne-made K-Hornet chambers are even closely similar. Therefore, it would be a miracle if any K-Hornet chambered with a different reamer than the one used to chamber this rifle had similar usable case capacity. The resulting chamber volume variation can result in significant differences in pressure from one chamber to the next. Use extra caution whenever working with any K-Hornet.

Never use any load described in this article in any rear-locking action or in any action that does not support the entire case head. If in doubt, abstain!

When I discovered CZ-USA had a custom shop, I had an idea. I have long wanted a long-barreled K-Hornet. I could build one around the CZ 527 action, or I could have the CZ Custom Shop build one for me.

At the 2015 SHOT Show, I discussed this with Jason Morton of CZ-USA. I asked if the folks in the custom shop could use my 22 K-Hornet reamer. He said, “Yes.” I asked if they could install a 0.224-inch groove diameter, 1:14-twist barrel. He said, “Yes.” I asked if they could install a 28-inch long barrel. He said, “Yes.” I described my budget to see if I could afford it. He said, “Yes.”

Shooting the Custom-Shop CZ 527, 22 K-Hornet is a genuinely pleasurable

experience. Velocityresults from the long, 28-inch barrel surpassed McPherson’s

wildest expectations. Accuracy results were as good as hoped and subsequent

load development has shown ever-better accuracy results. Cost of this US Optics

3.5-17X exceeds the cost of this rifle by several times. This top-end scope is far

more glass than McPherson would ever need on this rifle, but just exactly how much

quality is too much? It’s simply not possible to over-glass any quality rifle. This

excellent Nightforce spotting scope allowed his spotter to dope the wind.

So, I placed my order and tried to wait patiently. My good experiences with CZ rifles left me anxious to get to the range with this one. Soon, I was asking myself, “When is it going to get here already?!”

I am left handed, and while CZ offers left-handed models, the stock choice is extremely limited. When shooting from a benchrest I find right-handed bolt-action rifles are perfectly handy. So, I ordered a right-hand 527 with the varmint stock.

I have tweaked the triggers on several 527 rifles. A dependable 4-ounce let-off with the trigger set is feasible. Let-off of the un-set trigger is about 1-1/2 pounds, which is certainly fine on its own.

I wanted the chamber cut with my Manson Precision, K-Hornet reamer because Manson designed and made the reamer (according to my instructions) to minimize case working during full-length resizing with my Hornady die. Hence, full-length resized cases will almost perfectly fit the chamber.

In addition, I designed the reamer to create a chamber that fits the loaded round well and with a short throat and benchrest leade. My goal was to maximize case life and accuracy.

In a typical Hornet chamber, cut with a conventional reamer, chamber neck diameter is at least 0.006-inch larger than neck diameter of a typical round. In this chamber, chamber neck diameter is only 0.002- to 0.003-inch larger than the case neck diameter (depending upon vagaries of individual case neck thickness).

Therefore, neck working with each loading and firing cycle is far less, cases will last longer without neck annealing, and the chambered bullet is held closer to the center of the chamber, which improves accuracy.

Similarly, in a standard chamber, neck length is a whopping 0.065-inch longer than length of a maximum-length case neck. In this chamber, the neck is only 0.015-inch longer than a maximum-length case neck. Therefore, the bullet enters the chamber throat with less unsupported movement and less deformation.

Finally, the conventional Hornet leade does not match the modern benchrest leade design. The benchrest leade allows the bullet to enter the rifling more squarely and with less deformation, which should improve accuracy.

I never full-length resize Hornet cases used in the same gun. I neck-size using a modified Lee Collet die. This die fits the K-Hornet case and leaves short portions of the case neck unsized, at the mouth and at the shoulder, which eases bullet seating and reduces the chance of damaging these rather delicate cases. With periodic neck annealing, when using this die, case life is essentially unlimited.

A 0.224-inch barrel works with standard .22-caliber bullets. A 1:14-twist will stabilize 35- and 36-grain frangible bullets and conventional bullets up to 50 grains, but the 1:16-twist standard for the Hornet will not.

Compared to a standard 22-inch barrel, a 28-inch barrel has two advantages. First, it gives about 150 fps more velocity. Second, it reduces noise to the shooter (to about 1/4, since the muzzle is farther from your ear and muzzle pressure is lower), and it reduces downrange noise about half due to less muzzle pressure.

In the Hornet, no other propellant compares to Lil’ Gun. To avoid lot-to-lot variation issues, I obtained a lifetime supply of same-lot Lil’ Gun. Federal 100 and Remington 6-1/2 primers work perfectly with Lil’ Gun. I’ve been using Remington cases, which have the greatest usable capacity, and the ones I started with. Winchester cases have less capacity but are generally better. European cases have even less capacity but are usually of much better quality.

For best accuracy, I load modern bullets at close to 1.85-inch overall length—near 0.020-inch off the rifling in my chamber. I modify the CZ magazine to handle such rounds.

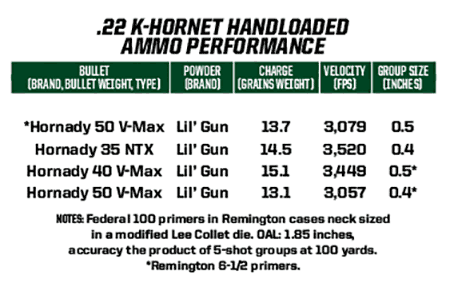

Loads in the following table showed normal pressure. Tested loads using Remington 6-1/2 primers in new Remington cases showed less primer flattening than the same type of primers in Remington factory .22 Hornet loads, which suggests pressure of the handloads was probably less. However, this is probably a misleading reflection of a lot-to-lot difference in functional rim thickness (headspace), a lot-to-lot difference in cup hardness, or some other factor or factors. Such differences often result in misleading differences in fired primer appearance.

Using naked bullets rather than moly coated increases pressure. For Remington cases, start 2-1/2 grains less than the maximum suggested here. In Winchester cases, 3 grains less, and for European cases, 3-1/2 grains less. Overall, the 6-1/2 primer gives better ballistic uniformity. Use only these primers, and if primer piercing occurs, progressively shorten the striker-spring.

Factory Hornet loads such as the Hornady with a 35-grain V-Max are among premium factory

offerings. Remington offers 45-grain softpoint and hollowpoint loads, and Winchester offer

a 45-grain softpoint and a 46-grain hollowpoint. European Hornet ammunition, when available,

tends to be superior, with regard to case quality and accuracy, however, at least some European

loads fall far short of matching the ballistics of domestic Hornet ammunition.

With the K-Hornet in the CZ 527 American with a 21.9-inch barrel and my best handloads, I have made many clean kills on prairie rats out to about 350 yards. The velocity advantage of the 28-inch barrel increases effective range by 10 percent. That, my friends, makes this Hornet entirely useful for most varminting on most days. I will never overheat this barrel. Wearing it out will be a lifetime goal, not a dreaded inevitability!

We live in the Golden Age of varminting. Consider this: These 40-grain K-Hornet loads shoot flatter with less wind drift than any factory .222 Remington load made in the old days using 50-grain tipped bullets.

Certainly, with the best modern components and when loaded to reasonable pressure, .222 ballistics far outclass anything the K-Hornet will ever do. However, for such an increase in performance, you pay a significant price because .222 loads cost more, make more noise, heat the barrel more, wear the barrel out faster, and generate more recoil. All of this for, perhaps 50 yards greater useful range.

The .222 took the varminting world by storm in the late 1950’s. The K-Hornet loads described in this article, using modern components and exceeding SAAMI Hornet length (and probably exceeding SAAMI maximum pressure), are far more effective than original .222 loads were.

Consider ammunition cost. At $25 per pound, typical Hornet loads use about 12 grains of propellant (4.3¢), .221 Fireball loads about 18 grains (6.4¢), .222 Remington loads about 21 grains (7.5¢), .223 Remington loads about 24 grains (8.6¢), and .22-250 Remington loads, about 40 grains (14.3¢).

While K-Hornet cases might not last as long as these other cases, Hornet cases are much less expensive. With careful handling during handloading and good case maintenance, case cost for the K-Hornet is likely to be less than for the .222 family and much less than for the .22-250.

As to barrel cost, before you see a significant accuracy loss, a K-Hornet barrel should last more than 15,000 rounds (new barrel cost per shot: 3.3¢), a .221, perhaps 10,000 (5¢) a .222 likely 7,500 rounds (6.7¢), a 223, maybe 5,000 (10¢) and, a .22-250, about 2,000 (25¢). We’re assuming here a cost of not less than $500 to replace a high-end barrel, and we’re talking about the life where accuracy is greatest.

Over a few days of serious varminting, savings with the K-Hornet will add up. Over a season of serious varminting the difference will cover a bunch of K-Hornet handloads. Over a few decades of serious varminting, the difference will cover the cost of this custom rifle and a large pile of Hornet ammunition.

Other issues, which are more important to me, include being able to see the hits and misses far better than with any bigger .22-caliber cartridge. I never have to worry about barrel heating (as long as I have targets, I can keep shooting). I don’t disturb other targets or neighbors as easily nor do I need to clean the bore during any varmint hunt. Maybe best of all, I don’t beat myself up with muzzle blast.

Hornady offers the best factory Hornet varminting load topped with the 35-grain V-Max

(above, left) at about 3,250 fps (in McPherson’s 28-inch barrel). It works well for

shots to about 250 yards. The more efficient 40-grain V-Max at 3,450 fps in the K-Hornet

(middle right) is far more effective and increases useful Hornet range to well beyond

350 yards, which is probably farther than most of us should expect to routinely make

solid hits. Even with an occasional shooter-induced flier, McPherson had no trouble

finding several loads that routinely placed five bullets inside 1/2-inch at 100 yards.

Both the .22-250 (left) and the .223 (middle left) rather dwarf any version of the

K-Hornet (middle right). Nevertheless, with best loads using modern components the

Hornet (right) is entirely adequate for perhaps 90 percent of all varminting.

Significant Hornet and especially K-Hornet advantages, when compared to larger

cartridges are, in no particular order: less noise, less recoil, less barrel

heating, longer barrel life, and lower cost.

A final point, while I do enjoy load tinkering, sometimes simple is better. K-Hornet loading is simple: Neck size and decap fired cases, seat Remington 6-1/2 primers, dump your worked-up charge of Lil’ Gun, and seat bullets (almost any 35- to 40-grain bullet will do!) to about 1.85-inch overall length. The resulting load will likely be accurate enough for most varminting needs—simple and simply great.

Hornet cases are a bit fragile and require more than average handling care while reloading. Using my modified Lee Collet die, the RCBS APS priming tool, and the RCBS Gold Medal seating die, reloading is fast and simple and I very rarely lose a case to damage.

Obviously, no K-Hornet load will ever provide the spectacular terminal performance of the .22-250. Indeed, spectacular kills beyond about 250 yards are rare. So, if you can’t enjoy varmint hunting sans extreme terminal acrobatics after a solid hit, even at longer distances, the K-Hornet is a poor choice.

While I find custom case conversions to be a fascinating process, simplicity has advantages. My entire process for fireforming K-Hornet cases is to fire factory ammo or load new cases with a full-power charge and fireform those. In both instances, I prefer to do this while varmint hunting.

When fireforming, best results occur when using the maximum safe and feasible pressure for the case and gun. Conservation of energy and momentum require the faster the case stretches to fill the chamber, the more uniformly it must stretch. Conversely, the slower it stretches, the less uniformly it can stretch. As such, thin zones are likely to excessively stretch and rupture.

Conclusions

A rifle from the CZ Custom Shop is an affordable way for the serious shooter to take a large step beyond the ordinary, off-the-shelf, rifle. For those who want something different, this is an excellent option. This Custom-Shop .22 K-Hornet is ideal for much of my varminting; it has advantages over any available off-the-shelf gun.

Custom 527

Maker: CZ-USA

P.O. Box 171073

Kansas City, KS 66117

(800) 955-6615

www.cz-usa.com

Action type: Bolt Action

Caliber: .22 K-Hornet

Capacity: 5 (standard Hornet length, Magazine must be modified to accept cartridges with the 1.086-inch OAL)

Barrel length: 28 inche

Overall length: 46.5 inches

Weight: 7 pounds (sans optics)

Finish: Polished blue

Sights: None, drilled and tapped for scope

Stock: Walnut

Price: $1,250 (depending on options selected!)