Know Thy Gun...

Know Thy Gun Shop

We all enjoy getting a little lead therapy — plinking, precision target shooting, bowling pin matches, cowboy action shooting, black powder cartridge competitions, fur-trade rendezvous, etc.

We give little thought to the danger involved, but we should think about our safety every time. We trust the used gun we bought to work correctly and the ammunition to be safe. In many cases, trust is misplaced. Statistically, 50% of gunsmiths are the worst in their craft. Think about it for a moment.

Questions

Here’s another thought; previous gun owners with no formal training completed much of the work done on used firearms! Who doesn’t know someone who files, hones and sands on the internal components of a gun to make it “work better”? Do they know what they are doing? Maybe, maybe not. Professionally trained gun smiths make a living fixing amateur gunsmiths’ mistakes!

How many gun show tables have you seen loaded with questionable home-brewed ammunition? Commercial ammunition producers have checks and standards in place to ensure they provide a safe product. What checks and balances were in place on the home-brew ammo? In most cases, none.

To be clear, retail ammunition makers are required to hold a Type 06 license from the ATF, and be bonded and insured for ammunition manufacturing. Most gun shops only hold a Type 01 license for buying and selling firearms. This is a crucial point. Suppose a gun shop or garage ammunition producer doesn’t have the proper license, bonding and insurance. In such a case, the victim (or next of kin) will not have medical expenses, replacement costs, and any pain and suffering compensated.

As the following examples show, failure to observe proper procedures and practices can result in life-threatening, catastrophic failures.

Failure — Case Study One

“Mr. Smith” purchased a used M1 Garand reproduction on an online auction site. The M1 Garand was from a limited run by a well-known and reputable firearm manufacturer.

The rifle was shipped to a local gun shop to complete the transfer background check. While receiving the gun, the gun shop owner stated he had some remanufactured ammunition for the M1 Garand. Along with the transfer fees, Mr. Smith purchased 20 rounds of the remanufactured 30-06 Springfield ammunition.

A few days later, the rifle was cleaned, inspected and loaded with eight of the remanufactured rounds.

The very first shot caused total destruction of the gun! The rifle exploded with such force broken and twisted parts were scattered in a 36-foot radius. Luckily, Mr. Smith only suffered minor injuries to his hands and ears.

The stock and internal parts were destroyed. The receiver and barrel remained intact.

Mr. Smith immediately contacted the gun shop where he purchased the remanufactured ammunition. He explained what happened and recommended all of the remanufactured 30-06 ammunition be pulled from the shelves until the investigation was complete. The gun shop owner became belligerent, stating all his ammunition was remanufactured in-house and safe. The gun store owner went on to boast an M1 Garand was strong enough to handle any load in it.

The manufacturer of the rifle was contacted next. While the M1 Garand was out of its warranty period, the company issued an RMA so they could investigate the root cause of the failure.

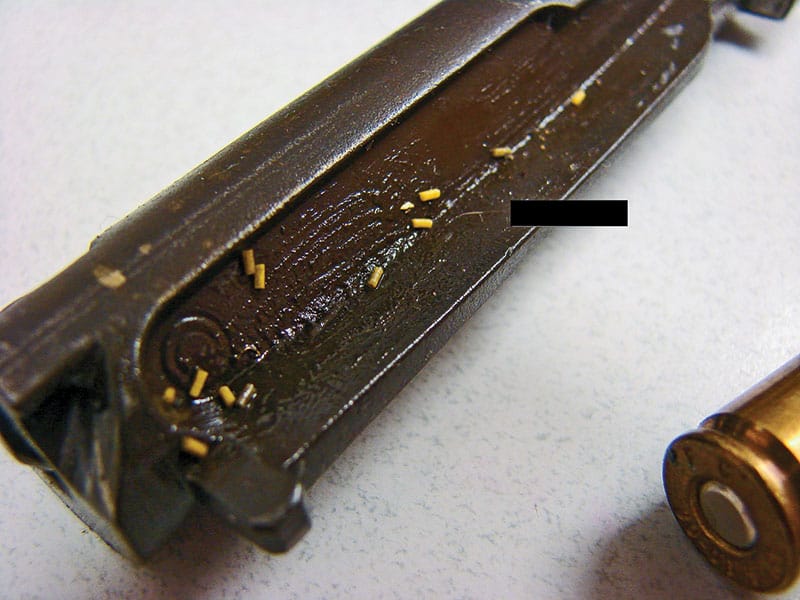

During their investigation, the remaining cartridges had three different powders, two different bullet weights and three brands of primers. Clearly, the rounds were not remanufactured using conventional methods.

Further investigation found the gun shop owner did not have the proper Type 06 FFL, bonding and insurance for manufacturing ammunition. Shockingly, the shop owner admitted he received all of his remanufactured ammunition from private, unlicensed individuals and provided them with store credit.

When the results came back, they further pointed at the faulty ammunition:

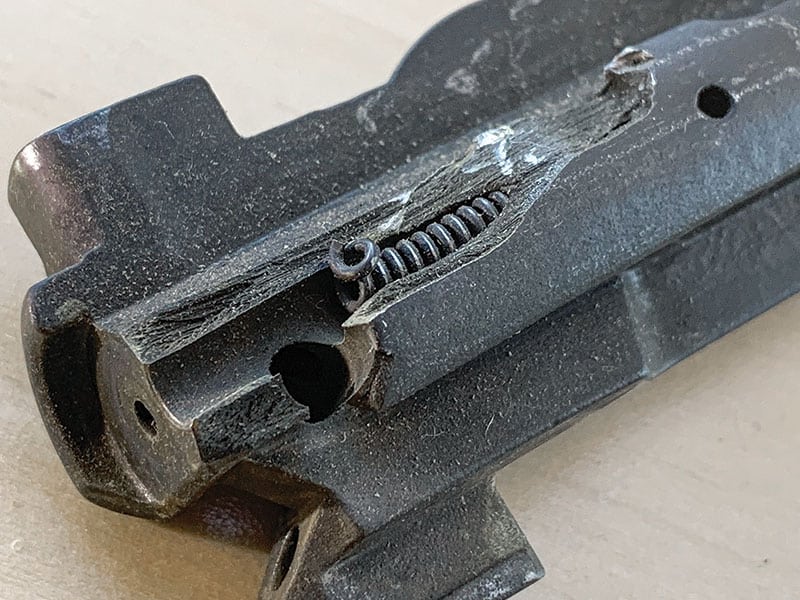

• The headstamp of the case was left on the bolt face, which is a sign of excessive pressure.

• The remaining kernels of unburned powder could not be matched up to any known gun powder.

• The cartridge at the time of the failure was fully chambered, and the bolt fully closed, which ruled out a slam fire.

• The pressure was so excessive it swaged the brass case into the unsupported area around the bolt face.

The root cause of the accident was determined to be unstable powder, most likely due to age and improper storage.

As news of this accident came out, others who purchased remanufactured ammunition from the gun shop came forward with similar stories of cartridge failures and firearm damage.

Armed with this evidence, Mr. Smith filed in small claims court. The gun shop settled before the court date. Shockingly, the gun shop was still selling homemade ammunition at the last report.

Failure — Case Study Two

“Mr. Jones” was a frequent competitor in turkey shoots, a popular sport in the Midwest where the competitors shoot at unique paper targets for cash and prizes. Serious competitors always look for the perfect shotgun to win the next match.

Mr. Jones won a used 60-year-old pump shotgun at a local auction. He cleaned and inspected the gun, but nothing unusual caught his attention. He tried to load the gun for a trial run, but the action didn’t close fully when chambering a round. Mr. Jones tried again, but the shotgun still didn’t close all the way. He should have stopped there and investigated why.

Putting more force into it, the action finally slammed closed. Sighting in, Mr. Jones pulled the trigger. The blast was so deafening Mrs. Jones knew instantly something was wrong from inside the house.

The explosion blinded and deafened Mr. Jones momentarily. As the shock faded and his vision returned, Mr. Jones realized part of his left thumb was missing. Another finger was almost severed. The bones in three fingers were broken and his palm was lacerated. The gun was a twisted wreck.

As Mr. Jones healed, he pondered what went wrong. Since the shotgun was 60 years old, modifications could have been made; safeties could have been defeated. While the gun appeared in good condition, all it would take is honing a part too much, reducing spring pressure, or removing the right screw to make a gun unsafe to fire.

No professional investigation was done on the shotgun. The only indication something may have been wrong was the resistance experienced in closing the action. In the final analysis, the failure was most likely due to poor gunsmithing or a broken part.

In reality, the shotgun may have been sold because of a known defect. I am sure many of us know someone who thinks they’re clever by selling off a problem firearm to an unknowing buyer. Caveat emptor — let the buyer beware.

The current conditions in the marketplace have sellers digging old ammo out of the garage and basement to sell at gun shows. The quality and safety of these rounds have to be questioned. With the prices of firearms reaching record heights, relics that should be left hanging above the fireplace are making their way back into shooter’s hands.

We all need to be vigilant and scrutinize what we are buying. Don’t let greed or desperation cause us to take risks. Mr. Smith and Mr. Jones were lucky. Both accidents could have been fatal. Don’t let it be you.