Powder names can be awfully confusing at times. For instance, among IMR brand powders there are SR-4756 and SR-4759. In Lyman’s newest 50th Edition Reloading Handbook on page 528 there are 127 smokeless powders listed approximately by burn rates from fastest to slowest. SR-4756 is in 34th place but SR-4759 is at 53rd place. The number/names are similar but the burning rates are not. Then there are Reloder 7 and Accurate No. 7. Reloder 7 is at number 65 but Accurate No. 7 is number 39, with the former being most definitely a rifle propellant and the latter a powder for handguns. Getting powders confused is dangerous.

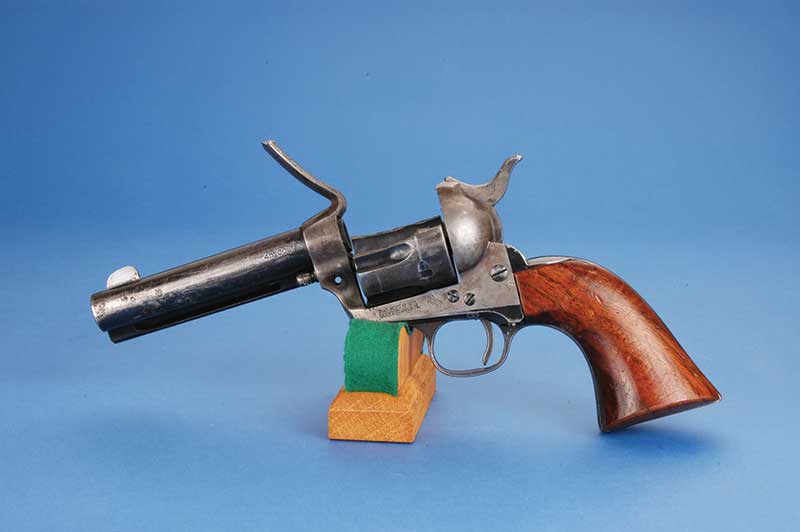

Stubbornness gets people in trouble at times. When I was a mere 19 there was an older gent at my local gun club firing a cap-and-ball pistol with Alcan smokeless shotgun powder. I said to him, “Don’t you know that’s dangerous?” His rely was “Kid, it isn’t if you know what you’re doing.” With the next shot his revolver’s barrel split open like a tulip. Should I have not laughed as I left the scene?

More recently I personally know of a low number US Model 1903 Springfield blown to pieces and hospitalizing the shooter. He had been warned not to shoot a low number ’03 but since he was using light loads with cast bullets, he figured all would be well. It wasn’t.

Be Careful!

We Want Our Handloads To go BANG!-NOT BOOM!

A week before this writing I was standing out in my yard shooting at a newly acquired steel target with one of my very collectible US Model 1911A1 .45 Autos. On the first shot of the second magazine full with my cast bullet handloads something went very wrong. My hand stung. So did my face. The .45’s grips fell to pieces and the slide locked partially open. I mean locked—there was no budging it.

A case head had ruptured. And I’m pretty sure the cause was an overload of powder. Now I want to stress this before going on—I am one of the most careful of handloaders. That said, the offending cartridge swelled the barrel’s chamber enough to require a gunsmith’s services to get it out. To the benefit of my finances, only the barrel and grips were damaged and replacements for those items are in place now with the pistol functioning perfectly.

This must be stressed also. I was wearing shooting glasses or else my vision would have been damaged because my face took a smattering of particles with enough force to break the skin. The incident could have been much worse.

What happened? The cartridge could not have gotten a double charge because the Dillon Square Deal progressive press on which all my .45 ACP’s are loaded has an auto-indexing feature. I chose it precisely for this reason. My only idea as how an overcharge got into the case is powder bridged in the measure, meaning another cartridge got a sub-charge and obviously the one mentioned above got way too much powder. The sub-charged cartridge could also lead to problems so I’m currently engaged in pulling the bullets on every single one of the several hundred .45’s loaded during this session.

How can this problem be avoided in the future? I see two methods. One is to raise my seating position when using the Square Deal so I can see into the cases after powder is dispensed. Standing would also accomplish this but my oft-injured back won’t take such abuse. A high stool is my remedy. However, I think combining better visibility with an additional factor might be even better. The factor is to use IMR’s Trail Boss powder.

Trail Boss was introduced about a dozen years ago. As the name might indicate, it was in great part aimed at the Cowboy Action crowd. Trail Boss was designed as a fast burning powder but it is “fluffy” so a low grain weight charge takes up considerable case capacity, which obviously helps prevent double charging. For example, my standard charge of Trail Boss in .44-40 with 200-grain lead bullet is 6.0 grains. A double charge of 12 grains fills the case to overflowing. A bullet couldn’t even fit into the case.

If you readers are thinking right now, “Duke, you’re a dummy. Trail Boss isn’t listed in the manuals for .45 ACP for the very reason you mentioned. It takes up too much case capacity.” If indeed you were thinking this, you would be correct on only part one of the statement. I could not find a reloading manual listing Trail Boss for .45 ACP. But, being the clever sort I am, my attention turned to Hodgdon’s very fine website for reloading data. It gave suitable charges of Trail Boss in .45 ACP with 230-grain bullets as starting at 3.5 grains and going to a maximum of 4.5 grains.

I found 4.2 grains of Trail Boss with 230-grain lead RN/FP bullets by Oregon Trail functions all my 1911 pistols perfectly. If for some reason a double charge was inadvertently dropped into a .45 ACP case, it would immediately be evident by the spilled powder. Hodgdon’s web data gives a velocity of 761 fps for their maximum load. My chosen 4.2 grain charge with cast Oregon Trail bullets clocked 760 fps from one of my 1911A1 with chronograph start screen at 6 feet. These are my fun shooting, practice, plinking handloads. For anything more serious I’ll go to factory ammo.

OK, I solved my problem with Trail Boss and the .45 ACP. What else? Fellows and gals, all too many guns get destroyed or damaged every year. It seems most often we handloaders are the culprits

Then there is the matter of warning signs. If something seems amiss there probably is something amiss. Smart people stop shooting then. Experienced people stop shooting then. In 2009 I let an inexperienced young fellow shoot my M1 Thompson .45 Auto submachine gun. The Thompson stopped firing in mid-burst. Before he could be stopped he pulled the bolt back and started firing again. My Thompson gained a ring about 6 inches from the muzzle. Primer force alone can push bullets well into barrels but usually not out of them. Firing another round after a stuck one puts a ring in the barrel at the base of the stuck projectile. The ring is a bulge in the barrel steel caused by the air being compressed between two bullets. (If the M1 Thompson and Model 1911A1 .45 Auto incidents had not happened 8 years apart I’d think they were related.) Anyway, a replacement Thompson barrel wasn’t much more expensive than a WWII vintage 1911A1 barrel.

Usually stuck bullets are handloaders’ mistakes but not always. I have a box of .32-20 factory ammunition from one of the two largest ammunition manufacturers that performs thusly in revolvers. Point the barrel upwards and it goes “Blam.” Point the barrel level and it goes “Bang.” Point the barrel down like you would when shooting at a rattler and the round makes a “fizz” sound. The bullet sticks a few inches into the barrel. The ammo does this every single time I’ve tried it. The remaining rounds in the box are saved for demonstration purposes.

Then there is the matter of rifle/ammo mix-ups. It amazes me how many of today’s firearms enthusiasts do not actually know what caliber their rifle or handgun is. As with powders, so many cartridge names are confusing anyway. Back in the ’70’s Remington changed the name of their .280 to 7mm Remington Express. How many of those cartridges found their way into 7mm Magnum chambers is unknown. I have an 8mm Mauser case in my collection obviously fired in a .30-06 chamber. Supposedly the rifle wasn’t damaged. But I have heard of .270 Winchester rifles wrecked when a .308 Winchester cartridge found its way into the chamber.

Another fellow might have stopped shooting his Model 1896 Swedish 6.5mm rifle when the primer in his 3rd round fell out of the case upon opening the bolt. He did not. With the 4th round the rifle came apart. Luckily he was not hurt.

As a rule, I don’t encourage shooting smokeless powders in cartridge rifles made in the black-powder era. For the most part Lyman’s 50th Edition manual agrees with me but does give .45-70 loads specifically for Trapdoor Springfields, Sharps, Remington rolling blocks, etc. The problem that might arise is the age-old double-charge. A friend managed to do so using 5744 in a .45-60 Winchester Model 1876 (original—not replica). It blew the barrel clean in two. Again no one was injured.

The 8mm Mauser cartridge case (above, center) was obviously fired in a .30-06 chamber. It is bracketed

by a .30-06 (left) and an 8mm Mauser (right). A handloading step as simple as seating primers can be done

wrong (below). The backwards seated primer at right fired but did no harm. The sideways seated one at left blew

the extractor out of the rifle. Check your loads!

Pouring Lead

Let’s not forget bullet casting. To do this we must fiddle about with molten metal! The concept alone scares some people. I’ve entered more than one person’s casting area to observe lead splatters hanging from the ceiling. After the fact it is laughable, but when it happens, there is a good chance someone also got splattered. This isn’t so laughable. Eye and skin protection should be worn when casting.

My understanding is now there are powder-check dies for progressive presses with enough die stations. They will buzz if too much or not enough powder is present. This is a wonderful idea but Square Deal presses can’t accommodate another die station. Best advice there is to be observant (a job I intend to excel at from now on) and/or use a powder that makes it difficult to get yourself in trouble. (This I will do whenever possible.) And whenever engaging in handloading and shooting we all just need be darn careful.