Essentail Inventory

Must-Have Tools For The DIY Gunsmith

Walk into a pro gunsmith’s shop and you’ll be overwhelmed with the assembly of tools and machinery. To work on a wide range of firearms efficiently while delivering high-quality results requires a significant equipment investment.

Fortunately, you can work on many guns correctly with a surprisingly small number of tools. We’re talking bare-bones stuff here — the absolute basics. There is, of course, more to it than loading up on box-store bargain hardware and calling it a day. For basic gunsmithing work, here’s what you need and what you need to know …

Basic Tool No. 1

Screwdriver Set — There’s no more important tool for working on guns than a screwdriver. There’s also nothing more cussed at or that’s ruined more guns (except maybe for a Dremel). Why? Many people use generic-type screwdrivers that don’t fit the screw slots.

Consider the common slot-head screw and driver configurations. The sides of the slot in a slot-head screw are parallel. Most mechanic-style slot-head screwdrivers are tapered. This means the tapered slot-head tip cannot fully engage the slot in the screw. The tip flats can engage only the top edge of the screw slot walls or engage only the outer edges of the screw slot (at the 6- and 12-o’clock positions). In either case, all the torque is placed against the slot edges, leading to buggered-up screw heads and possibly a scratched gun.

For gunsmithing, two benchmarks must be met. First, the screwdriver tip must completely fill the screw head. In the case of slot-head screws, the tip must also be parallel to engage the slot walls (not tapered). Second, the screwdriver tip must be correctly sized — meaning an exact fit (or slightly smaller) than the screw head diameter for optimal “bite.”

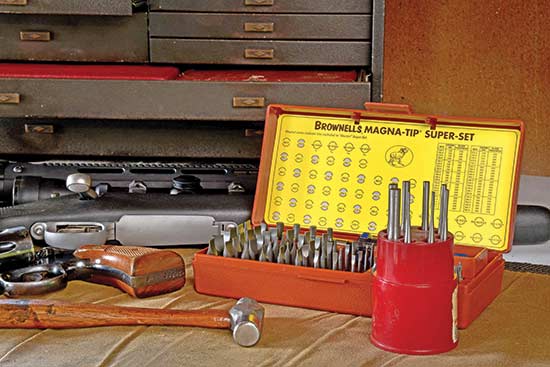

So, an investment in high-quality, gunsmith-specific screwdrivers such as Brownells’ Magna-Tip is money well-spent. A complete set ensures you’ll always have the correct-sized one on hand.

Basic Tool No. 2

Drive Pin Punch Set — As with screws, dowel pins are found on practically every firearm for securing cocking pieces, sights and other components. Since these pins come in many sizes, the home gunsmith should have a complete punch set. We’ve found no better punches for gunwork than Starretts.

And here’s a pro tip: New punches have sharp edges that can damage the work piece so it’s a good practice to chamfer these edges by chucking the punch in a hand drill and spinning it against a file until you achieve about a 1/64″ angled edge. Finish with 400-grit abrasive cloth. This chamfer allows the punch to easily follow the pin into the hole.

Basic Tool No. 3

Ball-Peen Hammer — Firearm dowel pins are generally driven in and out of the work piece. For this, an 8-oz. ball-peen hammer is ideal.

Another pro tip: Deformities in a hammer face can transfer to the work piece, so it is wise to keep your ball-peen hammer dedicated to gunsmithing work. You should also periodically dress the hammer face to remove the inevitable deformities. The best way to do this is to polish it with 400-grit cloth.

Regardless of the types of firearms you work on, a complete screwdriver set, quality punch set, and a clean and polished ball-peen hammer will get you through many tasks. From there, the basics really depend on the type of guns you tend to work on most. Let’s check the biggies by gun type:

Bolt Guns

Barrel Channeling Tool: One of the first steps many rifle owners take to improve performance is to bed the barreled action and free-float the barrel. A barrel channeling tool is a must-have to quickly and accurately provide the proper barrel channel clearance.

Firing Pin Spring Compressor: Periodically, the bolt mainspring needs to come out so you can keep the bolt’s inner workings clean and lubricated. For this, a firing pin spring compressor is your go-to item.

Pistols

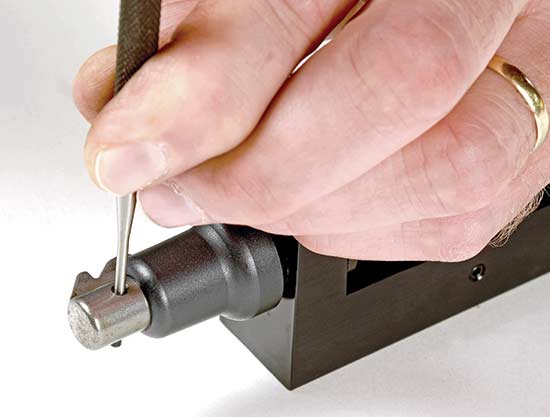

Sight Pusher: To install a new sight or to help zero the one you have, a sight adjustment tool should be standard issue for pistol owners.

Any specific tool should be included in your “gotta-have-it” handgun kit. For example, 1911 owners will need a barrel bushing wrench; GLOCK owners will want an orange armorer’s inspection plate or a GLOCK armorer’s tool.

AR Essentials

Bolt Ejector Tool: Like to run your AR-15 hard? Better like maintaining your bolt. For thorough bolt cleaning and replacing worn ejectors and ejector springs, this tool is your Huckleberry.

Armorer’s Tool: A must for AR builders and modifiers, this multi-tool removes and installs the barrel nut, receiver extension nut and muzzle device.

And there you have it — the Top Tools every gun owner should have for basic gunsmithing. Of course, once you see the difference quality tools make — not to mention the benefits of having the right one for the job — you won’t stop with these.