Shell Games

Shotshell Technology Marches On

When you think about it, shotgun design hasn’t changed a whole lot in the past several decades. The first over/under was a Beretta wheellock musket produced around the late 1600s. England’s Boss & Co. followed it up with the first modern over/under in 1909 and John Browning’s Superposed in 1931. Side-by-sides debuted in 1750 by the UK gun company Griffin and a century plus later in America in 1883 by Lefever Arms. Christopher Miner Spencer’s first pump was patented in 1882, 11 years before John Browning’s Winchester 1893, but Browning did patent the first semi-automatic. His legendary Auto-5 began production in 1902. Aside from those marquee moments, a lot of the design work has been modifications and enhancements.

New And Improved

But shotshells are different, for their improvements came after the gunning irons were developed. In the past few decades several boutique companies like Kent, HEVI-Shot, Apex, Boss and others join legacy companies like Winchester, Federal and Remington. One might say we’re living in a Golden Age of shotshells, with innovation stemming from the 1991 nontoxic shot for waterfowl legislation. Shotguns are sexy, but shotshells are where the rubber meets the road. Here’s a bit about how far we’ve come in not that long a time.

Hulls — One major improvement in shotshells came after the Civil War when E. Remington & Sons and Dan Lefever created their first breechloading shotguns. It was in 1877 and 1878, respectively, and to accompany them Winchester sold the first brass shotshells in 1877. These were brass hulls designed to be handloaded by the shooter. The upside to the brass shells was they could be reloaded multiple times. The downside was carrying a dozen added weight.

Later in the century, hulls were made with paper and only the base was made from brass. A Springfield, Mass. company, the C.D. Leet & Company, is credited with making the first shotshell hull from paper. These paper cartridges could be reloaded if they were kept dry, but even high humidity could have a negative impact. Paper became the go-to hull of choice until the 1960s with one exception being during the First and Second World Wars — reliability was of critical importance and brass hulls were used by the military

Another other big change regarded shell length. A lot of it had to do with the perceived need for speed, with hotter charges pitching out greater amounts and sizes of shot. Two-inch, 2 ½”, 2 ⅝” and 2 1/6″ lengths were common until a standardized 2 ¾” arrived on the scene in the mid-to-late 1920s. In 1935, Winchester launched the Super-X 12-gauge Heavy Duck in a 3″ shell. Mossberg introduced the 3 ½” 12-gauge in 1988 and Federal Ammunition created the ammo to suit.

The Introduction Of Plastic — While plastic was invented in 1907, it wasn’t used in shotgun shell hulls until the Winchester Super X Mark 5 debuted in 1964. Hunters and shooters loved these compression-formed hulls as they were strong and not affected by water or humidity.

The strength of plastic was preferred when using smokeless powders (increased compression). They’d fire when wet and star crimps replaced rolled crimps that further contributed to raising pressures. Winchester AA came out in 1965, and their durability made them a favorite among trap and skeet shooters who could reload the hulls multiple times. To keep shooters safe, Federal was the first to color-code their hulls by gauge starting in 1960.

Powder — Smokeless powder, called “nitro” powders because they use a variation of nitroglycerin, were developed in the mid-1880s. Black powder exploded when lit, but smokeless powder burned rapidly. The expanding gas is what created the pressure to successfully launch shot at higher velocities and speeds.

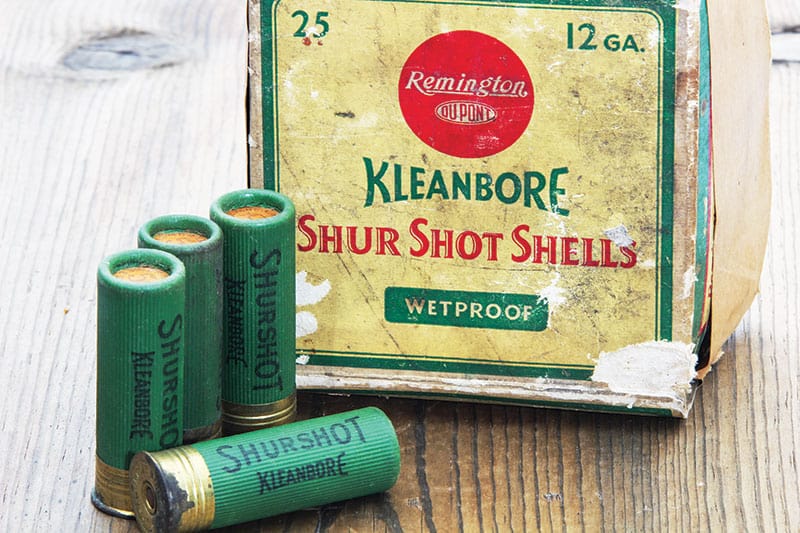

Mass Production Begins — Frank Chamberlin of the Chamberlin Cartridge Company in Cleveland, Ohio is credited with mass production of shells. His iron, brass and wood loading machine clamped to a table, and he initially loaded and crimped 400 shells an hour. Improvements increased the speed to between 1,200 and 1,500 shells an hour. Chamberlin is also credited with the introduction of the 25-shell box, which was easy for retailer and shooter alike. Remington purchased Chamberlin’s business in 1933, the year before they purchased Parker Bros.

Types Of Shot — While lead was the dominant material used for shot, Remington began experimenting with non-toxic shot back in the 1930s. During the Great Depression, hunters looked for an affordable shell, driving Big Green to focus on steel. This effort only increased when lead poisoning was discovered in Chesapeake Bay in the 1960s. When lead was ultimately banned in 1991, Remington was ready and launched Nitro Steel.

Originally, steel didn’t perform as well as lead. Pellets weighed ⅓ less than lead of comparative sizes and the lethal properties were considered inferior. While large-scale ammunition companies produced affordable nontoxic shells, a suite of boutique shotshell companies arrived on the scene, many in the past decade. They launched shot made from materials like bismuth and tungsten coated with copper, nickel, zinc and fluoropolymers. These shells are faster, with speeds ranging between 1,100 and 1,450 feet per second.

Biodegradable Shells? — A glimpse into the future. Hunters have already been contributing to a healthier environment by shooting nontoxic shells, but even this is about to change. An estimated 10 to 15 billion shotshell wads have been produced each year for the past 50 years. One wad is the plastic equivalent of two grocery bags, and their introduction into fields and waters is a problem. The race is on to create a totally environmentally friendly shell with Fiocchi leading the charge to develop shells that have a minimal to zero environmental impact.

Their EnviroShield initiative is designed to build on primers already lead- and zinc-free, and non-toxic shot by creating a 100% biodegradable wad. The wads sink in water that immediately begins the breakdown process. Ranchers won’t have plastic wads clogging their bailers and grazing animals like cattle and sheep won’t ingest the plastic. The final step, which is in the test phase, is the use of biodegradable polymers in extruded hulls. This way if a hunter drops a shell in a field, it won’t have an impact on the environment.

I never thought I’d say this, but it’s true — the 1991 ban on the use of lead shot for hunting waterfowl was a good thing. Why? Because of the need for a better performing non-toxic load, new companies were founded and the race to create better performing shells began. Shotgun shells are vastly improved, but riddle me this? How much better can they get? We’ll see…