Bullet Vs. Barrel

The Bullet You Choose To Reload Is A Unique Component

And Affects The Load’s Safety And Performance.

While my goal is to keep this discussion at an introductory level, some reader understanding will be necessary. Let’s begin with a few definitions and concepts related to cartridge components and how these work.

Propellant burning: Conversion from a dense solid into hot, energetic, voluminous gas.

Progressivity: Increase of gas and energy generation rate as the charge burns.

Obturation: Lateral bullet swelling, when the force on the bullet’s base exceeds bullet strength during firing.

Normal force: Resistance to stretching that increases bore diameter, as caused by bullet obturation or gas pressure.

Engravement resistance: Force required to engrave rifling onto the bullet’s surface.

Swaging resistance: Force required to swage an obturated bullet down to fit the bore (usually a significant factor only in revolvers, where the bullet swells into the forcing cone, as it exits the cylinder).

Sliding friction: resistance to continued movement of the bullet through the bore.

Usable case capacity (boiler room): Initial volume of the shell casing pressurized as propellant burns, before the bullet begins to move.

Dynamic boiler room: Increasing volume occupied by propellant gas as the bullet accelerates down bore.

Ignition Begins

When the striker crushes the primer pellet, the pellet ignites. It then burns extremely rapidly (deflagration). This generates hot gas. This gas flows through the flash hole and condenses onto the surface of the relatively cool propellant granules, located near the flash hole. This rapidly heats and thereby ignites those granules.

Propellant burning generates a large volume of hot gas. This rapidly pressurizes and heats the sealed space within the cartridge and begins to accelerate the bullet through the bore. Progressively, this heat ignites other propellant granules until most are burning and generating gas.

The rate of propellant combustion initially increases as more granules begin to burn. As the bullet accelerates down the bore, the volume of the dynamic boiler room also increases. Eventually, the rate of increase in the dynamic boiler room volume exceeds the rate of increase in combustion. At this point, chamber pressure has peaked. It will subsequently decrease as the bullet proceeds toward the muzzle.

Note surrounding gas temperature determines propellant burn rate. Within the boiler room, pressure and temperature are in lockstep. As pressure increases, so do temperature and burn rate; and, as pressure begins to decrease, so do temperature and burn rate.

In this instance, with .22 Hornet loads (left to right) featuring the 30-grain Barnes

Varmint Grenade, 36-grain Barnes Varmint Grenade and 35-grain Nosler Lead-Free

Ballistic Tip, bullet choice can dramatically alter down-range performance. Owing to

the superior ballistic efficiency, the 36-grain bullet (middle) adds about 20 percent to

useful Hornet range, and the tipped bullet (right) adds another 10 percent on top of this.

The longer bullets do have a single disadvantage. Hornet loads with these bullets will not fit

the magazine of most guns and therefore must be used single-shot—often a meaningless limitation.

Chamber pressure does not peak until the bullet has moved significantly. With normal loads, the larger the boiler room relative to bore size, the farther the bullet will move before pressure peaks. For example, in the .30-378 Weatherby Magnum, the bullet can move 5 inches before pressure peaks, while in the .308 Winchester the bullet typically moves about 1-1/2 inches before pressure peaks. In a target handgun load, the bullet might move less than 1/4 inch before pressure peaks.

In target handgun loads, combustion often consumes the entire charge very shortly after pressure peaks. As case size and charge filling increase, progressively more charge remains after pressure peaks.

When firing a conventional load with jacketed or cast bullets, acceleration force rapidly exceeds bullet strength. Therefore, the bullet obturates and stretches the bore, creating a normal force, and friction between bullet and bore. Weaker bullets obturate harder against the bore, and obturation increases as chamber pressure increases. Both factors increase bullet-to-bore friction.

For any given obturation force, dynamic friction between bullet and bore depends on the materials involved. These are steel for the bore (all steel has similar friction characteristics) and whatever material makes up the bullet surface. The latter includes: bullet metal (lead alloy, lead with antimony and tin), gilding metal (95 percent copper and 5 percent zinc), copper, brass (various alloys of copper, tin, lead, zinc, and other elements), mild steel (nearly pure iron), or perhaps some other material.

The force required to engrave the rifling into the bullet is relatively small, compared to the dynamic friction of an obturated bullet. Conversely, the force required to swage a revolver bullet back down into the bore after it has expanded into the forcing cone can be quite large.

A concept giving me considerable difficulty when I was a nascent handloader was the importance of the difference between “case capacity” and “usable case capacity.” This distinction matters because some bullets take up more of the total case capacity than other bullets do. Therefore, boiler-room volume depends upon the bullet used and how deeply the handloader seats that bullet (cartridge overall length).

These factors all influence how pressure builds as the round fires and how fast the bullet accelerates in response to the pressure. To understand this interesting facet of shooting and handloading it is necessary to understand the above noted aspects of how bullet choice influences accuracy, pressure and velocity.

After a half-century of handloading, almost as many years testing handloads for accuracy and performance, and testing loads in various ballistics laboratories, I am still amazed at how much difference bullet choice makes in most handloads.

Here, I will explore some of these factors briefly. While reviewing this information, please keep in mind exceptions always exist!

Consider handloading the .38 Special with 148-grain wadcutter bullets. In a typical load, this bullet is seated almost flush to the case mouth. As such, it occupies about 60 percent of the case. Here, changing seating depth (and, therefore, overall cartridge length) by 1/10-inch will dramatically alter peak pressure as the round fires (reducing pressure by 30 percent, for a longer load or, increasing pressure by 50 percent, for a shorter load). This is easy enough for any handloader to understand, seating the bullet deeper is exactly equivalent to using a smaller case—the load does not know any such detail, it only knows how big the boiler room is as the charge begins to burn.

All of these are 150-grain, 0.277-inch diameter bullets, and include (left to right)

the Barnes Solid, Hornady Roundnose, Speer Hot-Cor Spitzer, and Barnes X.

Anyone who believes, “You can use any bullet of the same weight in any load

without a problem…” is promoting a dangerous misconception. Among these bullets,

seated to the same overall length, loads with the shorter Hot-Cor had significantly

greater boiler room to work with, but nevertheless generated 33 percent greater

pressure than loads with the Solid did!

These cutaway dummy rounds demonstrate how changing seating depth

dramatically alters usable case capacity. The typical seating depth (left) for

the .38 Special 148-grain wadcutter bullet has a small combustion chamber.

Seating the bullet 1/10-inch longer (middle) and 2/10-inch longer (right)

dramatically alters load pressure. In otherwise identical loads at these lengths,

the shortest would generate more than twice the pressure of the longest.

These .38-55 Winchester bullets represent a few of the alternative bullet

designs and details not discussed in this brief article. Here’s a base and

side view (left) of a conventional paper-patched truncated-cone flatnose.

Paper-patching prevents bore leading. The truncated-cone (middle left) has

a baked-on moly-disulfide-saturated rosin jacket and thus requires no lube.

The paper-patched truncated-spitzer gas-check (middle right) is a very unusual

combination, and the truncated cone (right) has conventional grease lubrication

and a gas-check to eliminate bore leading. Myriad other cast-bullet designs exist,

and the selection in jacketed designs is even more varied.

This example is a good introduction to the fact bullet length matters, because, in terms of usable case capacity, seating a longer bullet to the same overall cartridge length is equivalent to seating the same bullet deeper. Bullet length, and seating depth, matter progressively less as relative case capacity increases (therefore, these are less critical in rifle loads than in pistol and revolver loads), but these factors always matter.

Here, I am ignoring the fact of how far the bullet can move before it hits the rifling. This free travel will influence how far and how fast the bullet initially accelerates. This is an important issue but it is beyond the scope of this article. All the novice handloader needs to know is bullet-to-rifling jump matters and most bullets in most handloads should have some jump, to assure the safety of the load and for best accuracy. I cover this in detail in my book Metallic Cartridge Handloading.

As an example of how bullet length matters in rifle loads, consider a typical .308 Winchester handload using 150-grain bullets. Here we will compare loads using conventional Hornady jacketed softpoint bullets both roundnose and spitzer. Other than nose shape, these bullets are identical in every way. Difference in nose shape results in a difference in bullet length of 0.14 inch. Now, consider loads using the same propellant and charge, with each bullet seated to the same overall cartridge length.

As the round fires, pressure with the roundnose reaches 53,000 psi. With the spitzer, pressure reaches 59,000 psi. In this example, both loads would be perfectly safe for normal use. But, if you were to develop a load with the roundnose bullet that generated near maximum pressure for the .308 Winchester, substituting to the spitzer without adjusting charge or cartridge length would result in a dangerous overload.

In this example, the roundnose would have about 70 feet per second less muzzle velocity. And, barrel time would differ significantly. (Barrel time is how long the bullet takes to accelerate through the bore.) These factors significantly influence external ballistics and accuracy.

The important thing to keep in mind in this regard is among bullets of identical weight and similar design, we commonly see much greater length variations. For example, looking only at 150-grain, 30-caliber Hornady bullets of conventional design, the longest is fully 0.355-inch longer than the shortest. Between these two, all else being equal, the longer bullet would generate 35 percent greater pressure—a perfectly normal handload using the shorter bullet would generate pressure in excess of a proof load with the longer bullet.

Now, let’s consider how bullet construction influences pressure. Novices who have thought about this usually expect this, all else being equal, harder, tougher bullets will generate greater pressure because it will take more force to engrave the bullet into the rifling. Generally, this is exactly backwards. Here, intuition fails because it does not take into account the fact bullet-to-bore friction depends critically upon bullet toughness, and that bullet-to-bore friction is a far more significant factor in retarding bullet acceleration than rifling engravement is.

Compared to a harder bullet, a softer bullet will swell (obturate) harder against the bore interior. This will increase friction and therefore retard acceleration more. It will take longer for the bullet to reach any point in the bore. Hence, as the bullet reaches any point in the bore, more of the charge will have burned, and the dynamic boiler room will contain more, hotter gas. With more, hotter gas occupying the same volume, pressure is greater.

At the Accurate Arms ballistic laboratory, I compared loads with 17 150-grain bullets in the .270 Winchester. I chose a perfectly normal load. Results with three bullets stood out as examples of how bullet choice influences pressure. These were the 150-grain Speer boattail spitzer, compared to the 150-grain Speer flatbase spitzer and the Barnes 150-grain roundnose brass solid, compared to every other bullet tested.

Speer uses the same core and jacket material in these two bullets. The jacket is identical in thickness and length. The only difference is in bullet base shape. The important difference is hardness of core and jacket. In the flatbase bullet, the Hot-Cor process softens (anneals) both jacket and core, which are therefore quite soft and malleable; in the boattail bullet, deformation of the jacket and core during bullet forming work hardens both, making those much stronger.

When seated to the same overall length, usable capacity is identical. The Hot-Cor bullet has a slightly longer bearing surface than the boattail. This minor difference results in modest and meaningless increases in engravement force and bullet-to-bore friction. Despite the similarities between these bullets, pressure with the softer, Hot-Cor bullet was 10,000-psi (15 percent) greater because the softer bullet obturated harder into the bore and, therefore, generated more bullet-to-bore friction.

McPherson recovered this leaded-brass bullet at The Friends of Billy Dixon

Range. It clearly shows rifling engravement and minimal disruption from firing

or long-range impact. Close examination of the surface between the engraved

rifling grooves shows the shank only expanded enough to slightly polish part

of the surface area. For this reason, bullet-to-bore friction was very limited,

which results in less pressure than would occur with a bullet that obturates

more easily. The late By Smalley and McPherson designed this .45-70 bullet

made as a small custom order. It is no longer available.

Now, consider the hard, tough Barnes brass solid. This bullet material and the gilding metal used in conventional bullet jackets have similar friction against steel. But, unlike a conventional bullet, once such a brass bullet has engraved into the rifling, it slides through the bore quite freely because it is tough enough to withstand the force of acceleration and therefore it does not obturate significantly. Therefore, bullet-to-bore friction is modest. In otherwise identical loads, this bullet generated 17,000 psi (25 percent) less pressure than the Speer Hot-Cor, despite the fact case capacity was significantly less with this longer bullet.

Now, consider how bullet construction influences barrel life. Contrary to intuition, with modern barrels shooting modern loads, barrel life is practically independent of bullet material. The explanation is simple: bullet-to-bore friction results in almost zero bore erosion. What wears out a properly maintained barrel is the cyclic stresses of firing, combined with corrosion generated by hot propellant gas.

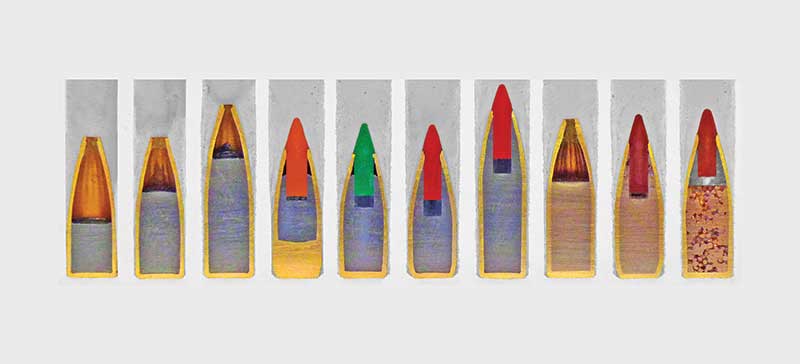

Cross-sections of various 22-caliber varmint bullets, demonstrating wide

variation in jacket and core design, tipping method, and core material. Lead

alloy is used in the left seven. Copper, in both powder and pellets, is used in

the right three. Many individual pellets in the core of right-most bullet fell out

during the sectioning process.

I am not saying bullet material and construction make no difference in barrel life. What I am saying is we have no good evidence these factors make a significant difference in barrel life.

But, exceptions are important. In magnum revolver loads, use of conventional jacketed bullets results in significant and rapid damage to the barrel forcing cone. Conversely, otherwise similar loads using hardcast bullets do much less damage.

The reason for this distinction has little to do with jacketed vs. not-jacketed and much to do with the fact cast bullets are much harder than the core of the jacketed bullets. The jacket is too thin to provide significant support to the core, so, these jacketed bullets obturate more while passing through the unsupported section between the cylinder and the beginning of the rifling (the forcing cone).

Because it had swelled more, it takes more energy (force) to swage the jacketed bullets back down to fit into the rifling. Swaging resistance is greater, so, jacketed bullets stress the steel of the forcing cone more than cast bullets do. Corrosion rate in steel depends critically on degree of cyclic stressing, therefore, jacketed bullets wear out the forcing cone faster.

How bullet construction influences accuracy is impossible to even begin to cover in an introductory article. Everything about the bullet influences everything about the accuracy of the load-and-gun combination. Instances when a bullet substitution makes so little accuracy difference it does not matter are rare.

Changing bullets will alter pressure, velocity, and accuracy, just as surely as it will alter external ballistics and terminal performance. Some substitutions are safe and others are unsafe. No authority on internal ballistics could predict with any certainty what any given substitution would do. Therefore, the safe path for any handloader to follow is to use an established recipe, obtained from a reliable source, exactly as described. And, keep this fact firmly in mind: The Internet is never a reliable source. As politely as I can state this: If you believe the Internet is a reliable source for any information, you are wrong, and, eventually, this mistaken belief will cause you grief.

Metallic Cartridge Handloading, Pursuit of the Perfect Cartridge, Mic McPherson, ©2013, 425 pages, photos, drawings, 8.5×11, softcover, $39.95, ISBN: 978-1-57157-371-1, Safari Press, 15621 Chemical Lane, Huntington Beach, CA 92649, (714) 894-9080, www.safaripress.com