About Bullet Casting

Memory Lane Beckons

Recently I sat down in front of one of my lead casting furnaces with misty eyes. The reason for the emotion was happiness because a variety of complications had kept me from casting bullets for over five months. There was some doubt I’d ever return to it. Contrary to the attitude of many bullet casters, I have never found pouring my own bullets an onerous chore.

Cast Away Your Cares

That’s not the same as saying I’d like to do it every day. But when weather is foul and deadline pressures have been met, I find making my own bullets a relaxing endeavor. I’m especially fond of audio books and while casting, I listen to ones ranging from murder mysteries to World War II history. During my bullet production sessions I don’t answer the phone or door and even tell Yvonne to leave me be.

Once, she came running to my casting area, excitedly saying, “Come quick, there’s an emu in the yard!” Thinking it was ridiculous, my response was “Go away.” She persisted, so sighing in frustration I set the lead dipper and mold down and stepped out of the shop. Sure enough a six-foot-tall emu stood there staring back at me. It eventually wandered off and we never saw it again.

From the first grade, school was a most hateful thing for me. One of the reasons I miraculously ended up with a BA Degree in journalism was I returned home nigh-on every weekend to target shoot with one revolver or the other. If it rained or snowed then time was devoted to casting more bullets. For spring break of 1971, with no funds or desires to head toward a beach, I set myself a goal of casting at least 10,000 bullets and actually ended up with 12,000. The majority were .38/357 semi-wadcutters but there were a thousand or two each of .41s, .44s and .45s. This was all done with single- and double-cavity molds. As I remember most of those bullets came from Lyman mold numbers 358477, 41032 and 454190. I literally cleansed my hometown of wheel weights that week.

A good question here might be, “Did you use any special techniques to produce so many?” I did use the dual mold method, meaning filling one while the other cooled. It didn’t hurt that beside my chair was a 100-lb. anvil upon which the cooling mold was set. The huge hunk of steel sucked the heat right out of the mold blocks, speeding up the solidifying process considerably.

Toward the end of college, I acquired a Model 1903A3 Springfield and took up casting for rifles. Good .30-06 results with Lyman mold #311291 throwing a 170-grain RN came easily and caused me to continue to this day, trying cast bullets in most of the rifles I’ve acquired.

Tough Times

During school years, money was tight and what cash and coins left after buying necessities were spent on powder and primers. If buying bullets — cast, swaged or jacketed — had been part of my handloading program, weekend shooting would have been greatly restricted.

During late college years, I began traveling westwards in summers. One year, I took along my S&W Model 19, a Colt SAA .357 Magnum and a Lyman 310 “tong” tool with 500 sized and lubed bullets from my Lyman mold #358477. To my pleasure, four other fellows in our bunkhouse also had .357 Magnum revolvers. We had some fun evenings shooting but — as none of the other guys were handloaders — those 500 bullets didn’t last too long.

Thereafter, a propane camping stove, cast iron pot and dipper were added to my gear. Also the 310 Tool was set aside in favor of something I named my “reloading board.” It was about a four-foot-long, 2″-thick plank on which was mounted a single stage press, powder measure and lube/sizing machine. In use it was c-clamped to any available flat surface. Even after settling in one spot, this lash-up kept me in handloads albeit an electric furnace replaced the propane camping stove.

The Addiction

In time, affluence allowed me to become a “bullet mold junkie.” Literally, I’ve owned hundreds of molds ranging from .22s to .58s and from one to eight cavities, collectively dropping bullets weighing from 45 grains to 660 grains. Along the way, molds for bullet designs found unsuited to my pursuits were sold, traded or given away and the others — which gave fine results — have been treasured and NEVER, NEVER loaned.

Then, in 1985, came an impetus to my bullet casting. It is called Black Powder Cartridge Rifle Silhouette. It involves firing at metallic cutouts of animals out to 500 meters with single-shot, exposed-hammer rifles designed before 1896 or replicas thereof. Also bullets could be lead-alloy only. Brothers, did I get involved!

Needing to hit a ram silhouette measuring only 12″ deep from belly to backbone at 500 yards requires considerable precision. The result was many competitors turned to custom-made molds or prevailed on companies such as Lyman, RCBS and Redding SAECO to introduce new special silhouette designs. All this just served to increase my mold addiction. I’ve now owned over 50 BPCR Silhouette bullet molds while firing tens of thousands of rounds in load testing. This endeavor determined many bullet designs are suitable — the key is consistent casting, meaning variances of only a few tenths of a grain in a run say of 100 or so.

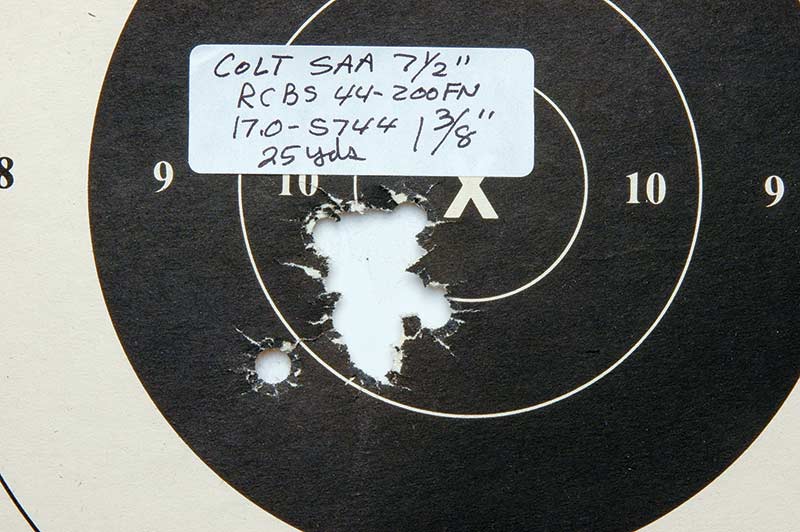

With age and accompanying infirmities, silhouette range time for me is reduced. For recreational shooting, I like shooting steel with handguns; most often Colt SAAs. For this, my own cast bullets are preferred. Some years back, a reader messaged saying, “I’ve just started casting bullets but they certainly don’t look as good as yours in the magazines.” My reply was; “There are two factors involved here. First, I’ve been casting for a half century. Second, I get to pick the ones shown in the photographs!”