Rock Your Roller Lock!

HK Modifying The Classic Battle Rifle

Few guns have had the near-universal acceptance enjoyed by Heckler & Koch’s roller-lock family of weapons. From the iconic 9mm MP5 SMG to the .308 G3 battle rifle, roller locks have been used and manufactured around the world.

A Short History

After WWII, Ludwig Vorgrimler, a Mauser engineer who had worked on the wartime StG45, refined the design into a .308 rifle later adopted by Spain as the CETME (Centro de Estudios Tecnicos de Materiales Especiales). A further refined version was later manufactured by Heckler & Koch and adopted by the West German Bundeswehr in 1959 as the G3 (called the HK91 in semi-auto form).

In combination, these guns were made in the millions, which means parts — often demilled and imported from countries that have moved on to a different service rifle — are plentiful and cheap. Consequently, guns built with these parts are also inexpensive. How inexpensive? Century Arms’ C308 rifle, built using CETME parts kits, can be found in the $600 range, a price point where you’d be hard-pressed to find any semi-auto .308 with an optic rail. South Carolina-based PTR also produces reasonably priced copies built using HK-licensed tooling acquired from Portugal.

Roller locks have always been known for field-plowing reliability. Even while the mechanism was still in development, the guns were known for being able to function well with zero lubrication.

A lot has changed in the past 60 years and we’ve now all been conditioned by Eugene Stoner’s AR platform to expect tactical guns to be modular. Roller locks are, but in a different way. An AR can easily change barrel and caliber but you’re pretty much stuck with the pistol grip, buttstock, forend — even the trigger — unless you brought tools and have some time.

Roller lock guns are the exact opposite. The barrel is pinned into a trunnion welded in place and it ain’t going anywhere but virtually every other feature of the gun can be changed without tools.

The Magic Number is 10

First, a word on changing parts. Importation of the semi-auto roller locks was essentially banned in 1989 with an even more restrictive ban taking effect in 1997. In order to keep manufacturers from skirting the law by simply importing all the parts and assembling them here in the U.S., there’s a limit to the number of imported parts in a finished gun.

This law is 18 USC 922(r) and states these guns can’t have more than 10 imported parts (from a list of 20) in order to be legal. Therefore, when you change parts, make sure you stop at 10. The foreign-made part may be absolutely identical to the U.S.-made one but if it’s imported, it counts against you. This is no secret, and manufacturers often list the parts counts for the guns they make or can supply them on request. So before you add a cool German metal trigger housing, make sure you’ve got enough parts left to keep your gun compliant.

Since the G3 and the original CETME — the source guns for most surplus parts — are select fire, make sure you don’t wind up with a collection of parts which could create a full-auto firearm. Possessing all the parts is a crime even if they’re not assembled!

Optics and Iron Sights

Now you know how to stay legal so lets move on to the fun part, starting with the top of the gun. First mainstreamed by builder PTR, a 1913/Picatinny rail on top of the receiver makes the gun every bit as optically flexible as a flattop AR. The only complication is with large scope objectives — you may need tall rings or a riser to make sure the scope clears the cocking handle, which must rotate upward toward the scope to lock the gun open. If you buy a gun without a rail, you can have one installed but there’s welding involved so it’s much less trouble and expense to buy a gun with one already in place.

CETME-style iron sights (also used on the earliest G3’s) have a multiple-leaf rear and tapered post front that can’t be changed as I’m not aware of any aftermarket replacements. The drum style, however, can be upgraded with night sights available from several sources.

Adding a Trijicon sight to the rear of my 16″ PTR91 was easy. Remove a screw in the rear sight base, push the night sight down into place, reinstall the screw and it’s done. Changing the front requires drifting out the roll pin holding the front post in place. It’s a pain and don’t even try it without using roll pin punches (I got mine from Brownells). Otherwise the punch has a tendency to force itself down inside the roll pin, spreading it and locking it in place (ask me how I know).

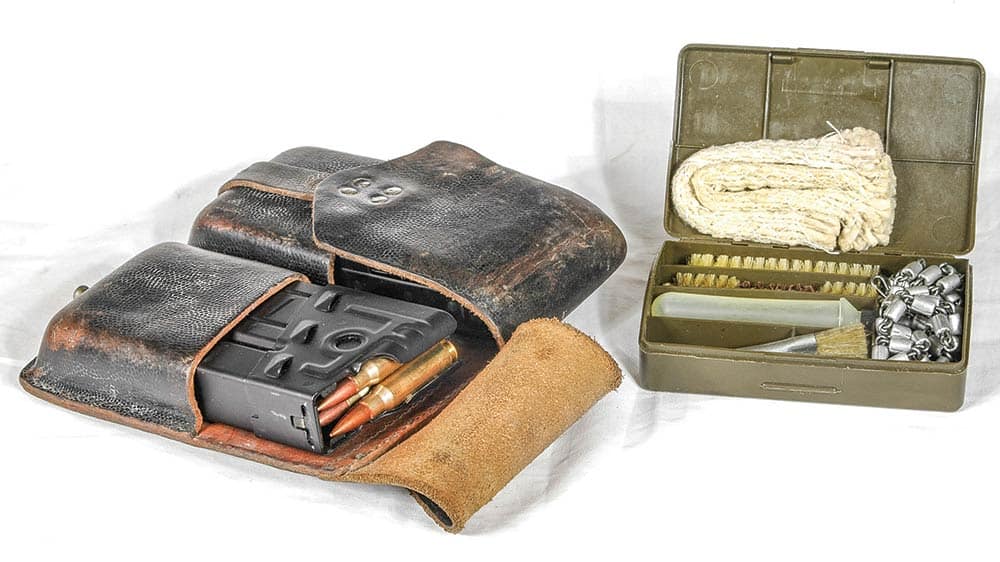

Make sure the gun is firmly clamped in a padded vice when you try to drive the pin out and apply protective tape to any part of the gun the punch or hammer may contact. This is particularly important when working from the rear, as the punch lines up on top of the cocking tube. Speaking of the cocking tube, one of the cool things about the C308 is it retains the CETME-style cleaning kit container which snaps into place in the front of the cocking tube. It is held in place by a detent you can depress with a bullet.

Left: Jeremy changed the original front post for a Trijicon tritium unit. Middle: Jeremy’s C308 employs the CETME-style rear with multiple apertures and a “V” for close range shooting. Right: The PTR employs the drum rear sight.

Brakes And Furniture

Roller locks are famous for both reliability and recoil, so aftermarket brakes are popular. The C308 is equipped with a smaller brake using chevron-shaped ports (an idea pioneered by Frank Pachmayr) to reduce recoil while PTR rifles generally come with the original birdcage style.

I replaced the PTR’s birdcage with an FSC brake from Primary Weapons Systems combining elements of both a flash hider and an effective brake. On the C308 (which uses a 5/8 x 24 thread pattern instead of the standard 15 x 1 metric thread of the PTR), I installed an MZL MAX device from NG2 Defense. The Muzzle Max benefits from the same Advanced Flow Dynamics technology found in the company’s Maxflo suppressor. The Muzzle Max directs the blast forward, saving your ears and the ears of those around you.

Both muzzle devices and sights require tools to change; the furniture, however, does not. The buttstock, forend and pistol grip are all held in place by simple push pins similar to an AR. Unlike the AR, however, they’re not captured and come completely free when pushed out. If you’ve ever wondered why HK stocks usually have two holes at the back, these are provided as a place to insert the push pins while the gun is disassembled, making it less likely they’ll get lost. Still, it’s a good idea to have spares.

To remove the forend, locate the pin near the triple tree (the part into which the front sight is mounted) and push it out from right to left. Pull the forend down then forward and off it comes. On PTR and other G3-style rifles, the pin passes through a hanger missing on the earlier CETMEs. It was added to later versions of the gun in order to keep the forend from putting pressure on the barrel and cocking tube. Because of the lack of this hanger, some aftermarket forends will not stay firmly in place on the C308.

For those who like the classic look, many roller lock rifles came into this world with metal-capped wood forends. Slimline stocks are also abundant, sometimes retailing for as little as $5 even if the helpful metal heat shield is missing on many U.S.-made replicas. PTR’s slotted aluminum tactical forend will take as many screw-on lengths of rail as you’d care to add but is held on with a bolt instead of the customary push pin. M-Lok and KeyMod forends, which are available from Aim Sports, HKParts.net and other sources, are also held on with a screw. All-metal forends heat up quickly so rail covers such as VZ’s G10 Inter-Lok panels are virtually mandatory. Available in a number of colors and textures and for both M-Lok and KeyMod, they help protect your hands from heat and give better purchase on the rifle.

The buttstock uses two push pins which can be a little harder to remove than the forend one. Once removed the buttstock slides straight back and off, which will also free the rear of the trigger housing so it can pivot downwards and out.

Buttstocks vary from side-folders and aftermarket M4-style collapsible models to wooden and plastic fixed ones in black or green as well as the original collapsible stock. The A3-style collapsible stock slides forward and backwards on grooves pressed into the sides of the receiver, making for a very compact package. The only drawbacks are the price (they tend to run over $300), lack of cheek weld and the tiny footprint of the coarsely-checkered buttpad which will leave waffle marks on your shoulder every time you shoot. However, for compactness, nothing beats it. For those more interested in precision shooting than close-quarters battle, Magpul’s excellent PRS2 is available and is a favorite of mine when I’m shooting for accuracy.

Like the AR and FAL the recoil spring is part of the buttstock assembly, but unlike those guns it protrudes forward into the receiver and is held in place on a central guide rod rather than being contained in the stock itself. Since the spring assembly is a pain to deal with, I recommend having a spring assembly on each and every stock if you like to swap out furniture.

We now come to the trigger housing assembly containing the pistol grip, the trigger pack and the safety lever. Pivoting the safety lever up and pushing it out will release the trigger pack which can then be removed from the top. For those interested in a smooth, lighter trigger pull, there are several gunsmiths who specialize in improving the factory trigger because, as with anything else, some are better than others.

Trigger Housing And Mag Release

Most roller lock rifles come with the “Navy” trigger housing, so-called because it’s molded plastic instead of the more traditional metal housing with a separate plastic pistol grip. The metal housings are plentiful — I’ve seen them as low as $5 apiece — and usually come with three safety positions marked “S-E-F.”

They’re marked in this way because they originally came from select-fire guns and can’t be installed as-is on a semi-auto rifle. One acceptable solution consists of having a steel block welded in place to keep a full-auto trigger pack from being installed and narrowing or removing the ears on the front of the housing. The ears would usually be used to mount the housing to the receiver with yet another push pin but they won’t go over the shelf welded into place in semi-auto guns.

Changing to a metal housing is a popular modification for good reason: it just looks better. Also for aesthetics, there are metal or plastic housings with the ears modified — rather than removed — to fit on a semi-auto receiver and with dummy push pins glued in place on either side. Intended to make the housing look unmodified, this is called a “clipped and pinned” housing. I understand why people like them but I think making your gun look like a full-auto model is a mistake, especially in the current political climate.

While the G3 originally came with a combination pushbutton/paddle magazine release, several makers only offer a pushbutton release which is very difficult to use. Replacement can be a tricky prospect as the original paddle release mounts in the same hole as the full-auto trigger housing pin so some methods for installing the release can cause the gun to be considered an illegal machine gun even if it doesn’t change the function of the rifle.

There’s a description floating around on the Internet of an “approved” way to install a paddle magazine catch without drilling the crucial hole but until I see something on letterhead from the BATFE Technical Branch, I’d be very hesitant to do it myself. Sending a gun to a manufacturer whose method has been approved is probably the safest way to handle it for those of us not particularly interested in going to prison.

These are some of the major things you can do to the gun but it’s nowhere near the end of the list. There’s a seemingly endless world of accessories, including the amazingly inexpensive magazines (I bought mine for $1.50 each) and compact cleaning kits. There’s even a .22LR conversion which runs around $600 — not economical, but a pretty impressive piece of engineering and a lot of fun to shoot. Needless to say, there’s zero recoil!

For those in search of additional info, Blake Stevens’ Full Circle: A Treatise on Roller Locking (Collector Grade Publications) is the definitive work on roller lock rifles.

Black Dog Machine

Ph: (208) 465-1940

www.blackdogmachinellc.net

Bowers Group

Ph: (503) 992-8697

www.bowersgroup.com

Brownells

Ph: (800) 741-0015

www.brownells.com

Century Arms

Ph: (561) 2265-4500

www.centuryarms.com

Magpul Industries

Ph: (877) 4MAGPUL

wwww.magpul.com

NG2 Defense

Ph: (801) 692-7091

www.ng2defense.com

Primary Weapons Systems

Ph: (208) 344-5217

www.primaryweapons.com

PTR

Ph: (843) 358-2222

www.ptr-us.com

VZ Grips

Ph: (850) 216-1911

www.vzgrips.com/