Federal Ammunition 100th Anniversary

It's Their Party But We Get The Presents!

Federal Ammunition — celebrating its centennial year in 2022 — rose from a defunct shotshell factory into an industry powerhouse now partnered with brands such as CCI, Speer, Estate and others. For those of us who came of age when their innovations were a given, it’s easy to take for granted what they’ve done and what they’ve done first.

In The Beginning

Brothers Harry and Lewis Sherman worked at Western Cartridge and a couple of other ammo makers when they struck out on their own in 1916 to make shotshells in Anoka, Minn. Their dream died quickly with the reduction in demand at the end of WWI. By 1920 the plant was closed. Two years later Charles L. Horn, who owned a company manufacturing shot, was in need of paper tubes to package BBs. At first only interested in the machinery, he was quickly convinced to resurrect the entire factory and Federal as we know it was born.

Distribution was a problem, since other, larger makers had shelf space locked down in sporting goods stores so Horn cannily began selling his ammunition through barber shops, corner stores, even doctor’s offices — places he knew men would congregate. It worked. By 1924 the fledgling company had expanded from shotshells to rimfire ammunition and taken over the floundering American Cartridge Company founded by the Sherman brothers after their failure at Federal. This line of ammo became, and remains, American Eagle.

Horn remained president for over 50 years. Much of this time the primary shareholder was Franklin W. Olin, who also owned Winchester Ammunition and Western, which he had founded in 1898. This also probably explains why Federal’s .22 WRF ammo was actually loaded by Western.

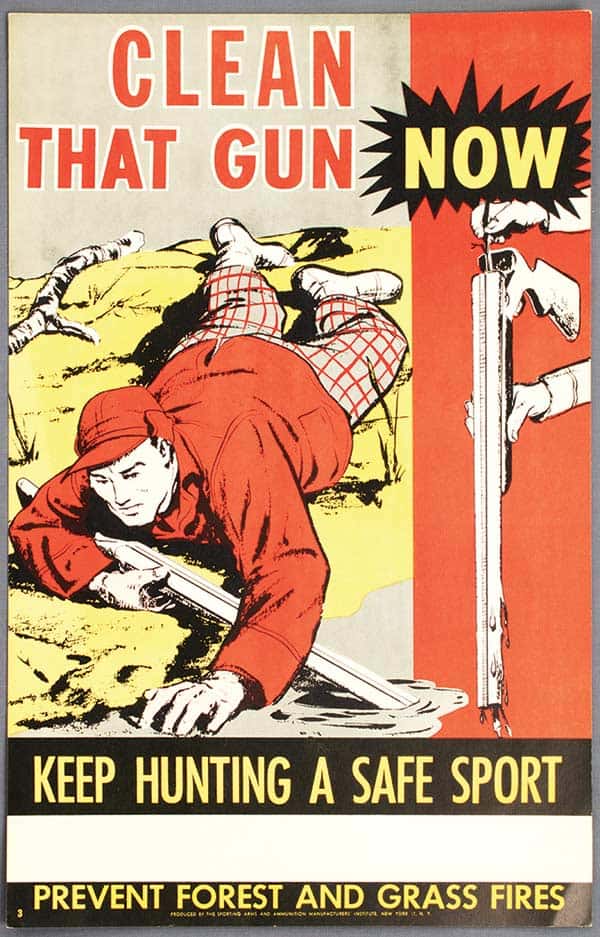

While the responsibility for safe firearms use ultimately lies with the end user, it’s both good business and morally appropriate to encourage safe gunhandling. As early as 1930, Federal began running ads advocating for conservation and gun safety. Federal didn’t stop at advertising, though: They developed the first steel shot load for waterfowling and in 1960, they introduced a color code system for shotshells, with 12-gauge hulls in red, 20 in yellow, 16 in purple, etc. The approach was well received enough that SAAMI industry standards now set aside the color yellow for 20 gauge only.

For Defense Of Country

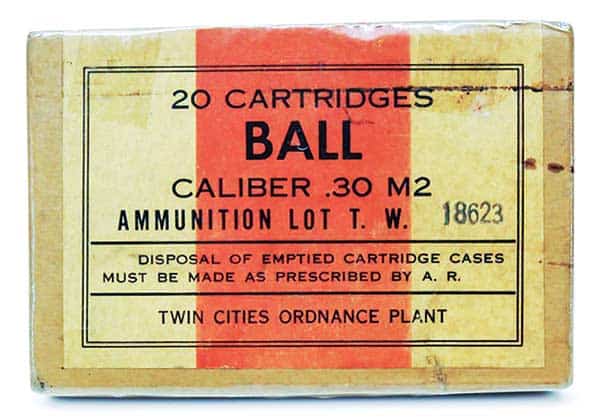

Safety, though, can mean more than one thing — in the context, it also means national security. There’s a good case to be made that we won WWII by out-producing the Axis. The Federal-operated Twin Cities Ordnance Plant (later “Arsenal,” then “Army Ammunition Plant”) was one of six Government-Owned Contractor-Operated (GOCO) facilities. It also produced military ammunition as needed during Korea and Vietnam, but WWII was perhaps its finest hour. After breaking ground in 1941, by 1943 it employed some 25,000 people, over half of them women, and produced enormous quantities of .30- and .50-caliber ammunition. Statistically speaking, if your grandfather landed on D-Day wearing a 100-round bandolier for his Garand, the .30-06 rounds in at least one of those 8-round clips were made by Federal.

Twin Cities was not their only contribution to government needs: Federal also made .45 ACP military ammunition headstamped FC and FCC (including National Match ammo) as well as shotshells. In fact, their military contribution began in 1940 with mortar ignition cartridges, essentially a specialized 12-gauge blank. This tradition continues — they provide mortar primers to this day.

Federal also provided military shotshells in WWII and the Korean conflict, then resumed in the late 1960s during Vietnam with the adoption of the XM162 (later M162) buckshot cartridge. Unlike the previous military shotshells, the M162, which remained the most commonly used military shotshell for at least the next 40 years, had a plastic hull in red — the color Federal had adopted to denote 12-gauge shells some years before.

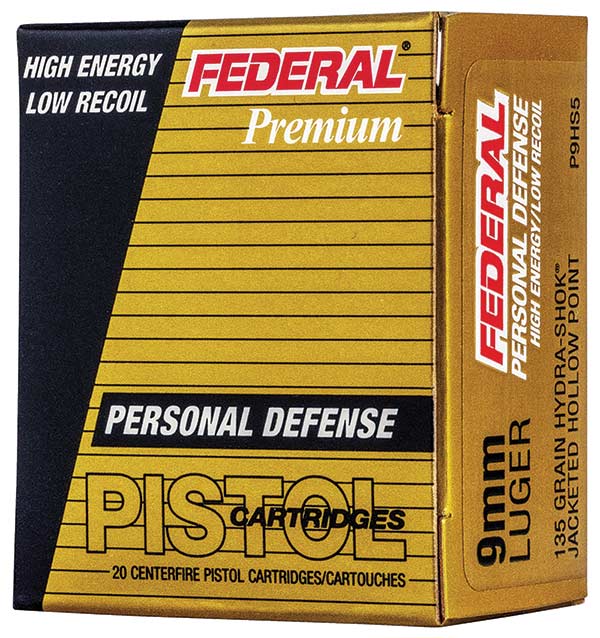

For defense of self

Federal’s revolutionary Hydra-Shok bullet, designed by Tom Burczynski and introduced in 1988, redefined hollowpoint handgun bullets used for self-defense. Instead of relying on more speed, which raises concerns such as chamber pressure and bullet weight, the Hydra-Shok put technology to work inside the nose of the bullet. Upon impact, a centrally located post redirected fluid entering the cavity and used focused hydraulic pressure to make the bullet open up, setting a new direction for second-generation hollowpoints.

Having defined what the front of a self-defense bullet should do, Federal then redefined what the back should do, again with the help of Tom Burczynski. In order to overcome the well-known problem of hollowpoint cavities becoming plugged and basically turning into ball ammunition, Federal’s Expanding Full Metal Jacket used a complete copper jacket over a soft rubber plug backed up by a lead core. Upon impact, the heavy lead base moves forward, splitting the pre-scored copper jacket and causing expansion. With no cavity to become plugged, or to classify the bullet as a hollowpoint in places where such bullets are not permitted, it’s brilliant engineering.

Federal’s efforts did not end at creating better bullets for existing platforms. In addition to developing the short-lived 9mm Federal caliber (a rimmed 9mm Parabellum, á la the .45 Auto Rim) in the 1980s came the joint creation of the .32 H&R Magnum. A ballistic improvement on the classic .32-20, the .32 H&R’s creation of a new package instead of warming up the existing cartridge eliminated the safety risk of creating a hot round able to chamber in fragile original guns.

Following the time-honored way of magnumizing a caliber, in 2004 Federal added an eighth of an inch to the .32 H&R case to create the .327 Magnum. While the .32 H&R rivals the .38 Special, the .327 functions at true magnum pressures and adds about 300 fps to the .32s performance. Both allow an extra round in the cylinder compared to a .38/.357 revolver.

The alert reader will recognize the same philosophy of a slightly smaller caliber at high pressure, creating similar ballistics with higher capacity, at work in Federal’s newest defensive handgun caliber, the .30 Super Carry. Other caliber innovations include the .224 Valkyrie, .338 Federal and 3 ½” 12-gauge shells — if your shoulder was wondering who to thank, now you know.

Game Getters

While peace of mind matters, most of us are far more likely to take game than we are to fire a handgun in self-defense, which means we’re more likely to actually see the results of Federal’s work in the hunting field. Here, also, Federal’s openness to change has inured to our benefit. For many years, hunting bullets consisted of a simple copper cup full of lead formed into a conical shape, generally with the tip of the soft lead core exposed to aid expansion. While it worked plenty of the time, there were applications such as dangerous game hunting for which it emphatically did not work.

This led to aftermarket experimentation in bullet design and construction techniques that would allow hunting bullets to expand without coming to pieces, since fragmentation is a sure recipe for getting clawed and/or bitten by something mad about being shot badly. We all know those names now — Nosler Partition, Speer Grand Slam, Woodleigh Weldcore — but for years they were a handload-only proposition.

Federal, with its Premium line, was the first to incorporate those into factory-loaded ammunition, later taking over production of the Trophy Bonded Bear Claw dangerous-game bullet. The Premium Safari line, which includes classics like .416 Rigby Magnum, .470 Nitro Express, .500 Nitro Express, a couple metric calibers and other classic African chamberings, remains a top choice for Africa-bound hunters. An informal poll of hunting professionals conducted by Dwight Van Brunt, and published last year by Field Ethos, found it tied for first at the top of the list — right where it belongs.