Freedom Arms' Biggest Big Bore

The 1/2"-Bore Fan Gets A New Cartridge And A Stellar One It Is

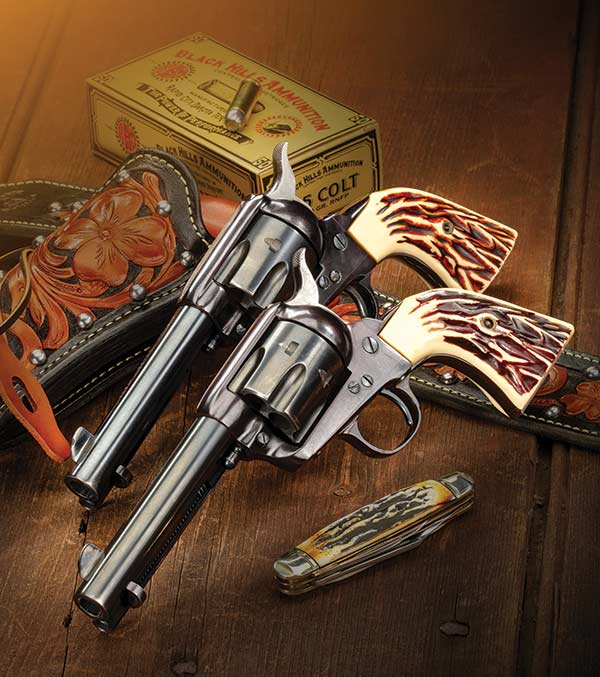

In the towering line of 1/2″ big bores, Freedom Arms has their very own proprietary cartridge — the .500 Wyoming Express, chambered in a five-shot Model 83. Although they did not know it at the time, readers got their first glimpse of the .500 WE labeled as a soon to arrive “mystery cartridge” in the 2005 Gun Digest. That picture was taken in February 2004, which gives some indication of the fact the .500 WE did not happen overnight. It actually took several years to bring this largest Freedom Arms cartridge and sixgun combination to fruition.

Let’s back up somewhat here and review the brief history of sixguns that brought us to this point. In the 1950s, prior to the advent of the .44 Magnum, a young gunsmith from Utah began experimenting with heavily loaded sixgun cartridges. The only two big-bore sixgun cartridges at the time were the .44 Special and the .45 Colt. The .44 Special brass was still being made in the old balloon-head style, while solid-head .45 Colt brass had just arrived. Because of this, Dick Casull began experimenting with heavily loaded .45 Colt Single Actions. It did not take long for him to reach the peak of performance the Colt SAA was capable of well below the performance he was looking for.

The next step was making special oversize five-shot cylinders for both Colt Single Actions and Bisley Models. It was still not enough — cylinders blew and top straps let go. The only way Casull could harness the power of his “.454 Magnum” was to build his own guns and that is exactly what he did. Those first guns were specially heattreated, five-shot, oversize-framed single actions. He finally had a sixgun capable of holding the desired power.

All this time he had been using .45 Colt brass, which to this day some still say, is inherently weak. It wasn’t then and it isn’t now. When Casull’s first factory produced .454s arrived in the late 1970s, .45 Colt brass was lengthened to prevent any .454 loads chambering in standard .45 Colt cylinders. If anyone had placed the heavier .45 loads in an older .45 Colt sixgun, especially a

black-powder Colt Single Action, the results would have been disastrous.

The first factory-produced .454s — and very few of them at that — came from North American Arms along with brass headstamped NAA. In the early 1980s, Dick Casull and Wayne Baker came together with the result being Freedom Arms producing Casull’s .454 in what is now known as the Model 83. In those early days it was simply the .454 Casull. The first factory-produced Freedom Arms .454 left the Star Valley, Wyoming, factory in 1983. When I discovered Freedom Arms in late 1985, they were building a whole lot more guns than they could sell. One of the reasons is the fear factor. Most gunwriters did not want to shoot the .454. At the time I was just getting started as a freelancer and I called Wayne Baker and was pleasantly surprised to find he would trust me with a test gun.

Taffin Tests An Early .454

I subsequently purchased that 101⁄2″ revolver and it is as tight today as it was 20 years ago and therein lies one of the great attributes of a Freedom Arms revolver. They have the precision of the finest crafted machinery while at the same time having the strength of a bank vault. From the very beginning Freedom Arms used the finest materials obtainable and built their guns with tolerances as tight as possible. They do not shoot loose. The first full-blown report I ever saw on the .454 complete with extensive testing and load development using a wide range of both cast and jacketed bullets was one I wrote and which appeared in our sister publication, American Handgunner, in 1986. I still hear from readers who tacked the load data above their reloading benches.

The .454 was a hard sell and for several years the vault at Freedom Arms was full of sixguns. It took awhile but that situation changed especially as handgun hunters discovered both the power and flat-shooting quality of the .454 Casull in a Freedom Arms revolver. As sales increased, Freedom Arms branched out into other chamberings such as the .44 Magnum, .357 Magnum, .41 Magnum, .50 Action Express and even .22 Long Rifle.

Special silhouette models were produced and the governing body of longrange silhouetting, the International Handgun Metallic Silhouette

Association (IHMSA), introduced a price ceiling rule, which effectively kept Freedom Arms revolvers out of competition. When this rule was finally lifted Freedom Arms virtually ruled the line at long-range silhouette matches. Personally, I used both .454 and .44 Magnum Silhouette Model Freedom Arms revolvers with 101⁄2″ barrels and special target sights in competition. Both the .357 and .44 Magnum Silhouette Models became very popular among the top shooters.

Biggest Of The Big Arrives

During the 1980s I also met a young gunsmith from Cody, Wyoming, by the name of John Linebaugh and one of the earliest articles I did for this magazine was on his heavily loaded custom .45 sixguns. Once he got his heavy .45s out into the sixgunnin’ world he started experimenting with larger cartridges with the result being his wildcat cartridges, the .500 and .475 Linebaughs. The former was based on the .348 Winchester case and the latter utilized much easier to find .45-70 brass. In both instances, the rifle brass cases were cut to 1.400″ using .511″ and .476″ bullets respectively. Oversized five-shot cylinders chambered in these two cartridges were fitted to rebarreled Ruger Bisley Models.

In the 1990s, the ideas of John Linebaugh and Freedom Arms began to merge somewhat. Bob Baker of Freedom Arms wanted to chamber the Model 83 Freedom Arms revolver in .475 Linebaugh, however there was a problem with the then existent brass made from .45-70 cases. The diameter of the rim of this brass was too large to allow five rounds to be chambered in a Model 83 cylinder. Baker made cases reducing the diameter of the rims to allow their use in a Freedom Arms chambered in .475 Linebaugh and found the cartridge work perfectly well. He was ready to go with it but would not do so until factory ammunition or at least factory brass was available with the proper rim diameter for the Freedom Arms revolver. This was solved with the advent of factory ammunition from Buffalo Bore and factory brass from Starline both properly headstamped and both with the desired rim diameter.

Freedom Arms .500

Once the .475 Linebaugh in a Freedom Arms revolver was reality, Baker could take a serious look at the .500. To chamber such a cartridge in the Freedom Arms cylinder would necessitate cutting into the ratchet at the back of the cylinder as well as reducing the rim diameter significantly to fit a Freedom Arms cylinder. There had to be a better way as far as Baker was concerned. That better way was a cartridge head spacing on a belt rather than the cartridge rim. That is the mystery belted cartridge I pictured in Gun Digest and it is now reality along with factory chambered .500 Wyoming Express Model 83 revolvers. Brass, designed to be used with large rifle primers, is available from Freedom Arms along with RCBS reloading dies. The proper shell holder is a No. 41. Since the .500 Wyoming Express is a belted cartridge, special care must be used in setting the full-length sizing die so it does not contact the belt. To make this simple, a special washer shaped gauge is included in the die set. This gauge is simply placed on top of the shell holder and the full-length sizing die is run down until it contacts the gauge. The gauge is then removed and cases can be properly sized. Freedom Arms also recommends seating and crimping be done in two separate operations and it is possible to purchase an extra seating-crimping die to simplify this process.

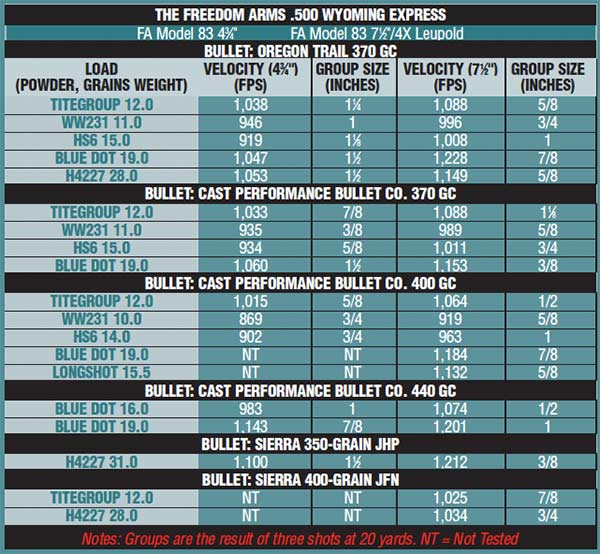

Factory chambered .500 WE revolvers are now available in three barrel lengths, the Perfect Packin’ Pistol candidate 43⁄4″ as well as 6″ and 71⁄2″ versions. I especially prefer the latter for serious hunting. For testing purposes two revolvers were obtained from Freedom Arms, actually one new revolver and one retrofitted with a .500 WE cylinder. The brand-new Model 83 is a PPP 43⁄4″ version while I returned my older 71⁄2″ Model 83 chambered in .50 Action Express to have a new cylinder fitted in .500 Wyoming Express. Both “Express” Big 50s use the same .500″-diameter bullets and any Model 83 .50AE can be fitted with a .500 WE cylinder, however, the reverse is not true as Freedom Arms is not offering .50 AE cylinders at this time.

Scope It Right!

While my 71⁄2″ Model 83 was being retrofitted with a new Wyoming Express cylinder I also asked Freedom Arms to install the SSK Industries T’SOB scope base. There are a lot of scope bases out there, some good, some not so good, but when it comes to really hard-kicking revolvers and single-shot pistols, I am not about to trust my face, head and scope to anything except the ultra strong T’SOB mount designed by J.D. Jones. J.D. knows hard-kicking handguns, scopes and mounts better than anyone I know.

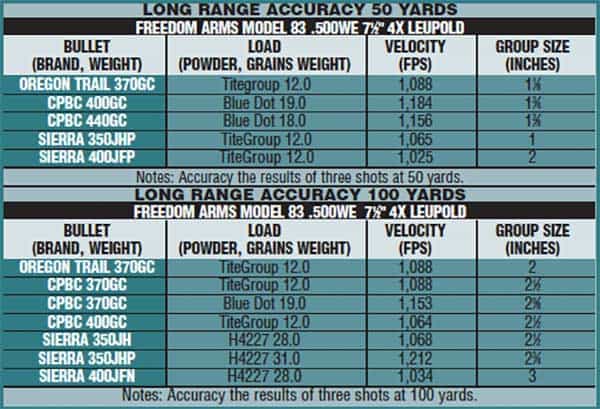

My scope of choice, also one I invariably look to for hard-kicking revolvers, is Leupold’s LER silver colored FX-II scope. I have been using Leupold’s pistol scopes for more than 20 years and most of my scope-sighted handguns wear scopes marketed by this Oregon-based company. The 4X Leupold FX-II scope has an easy-to-pick-up Duplex reticle and is exceptionally clear at all distances tested, in this case being 25, 50 and 100 yards. With 50-caliber holes and this scope, I did not need binoculars to see the bullet holes at 100 yards.

Oh To Be 20 Years Younger!

I do not hesitate to admit upfront the fact the .500 Wyoming Express revolver is capable of much more horsepower than I can handle. We are talking 370- grain bullets at 1,600 fps; 400-grain bullets at 1,550 fps and 440-grain bullets at 1,450 fps through relatively lightweight revolvers. The 43⁄4″ Model 83 chambered in .500 WE weighs less than three pounds, while the 71⁄2″ version, even with scope, base and rings comes in at around four pounds.

I soon found my upper limit to be 1,200 fps with a 440-grain bullet in the 71⁄2″ version, while the same load clocking out at 1,140 fps in the lightweight 43⁄4″ Model 83 was brutal to my hands sending shock waves through my left wrist. If I could turn the clock back 20 years, I’m sure I could shoot the heavier loads, however, I can’t so I can’t. I do know I can kill anything that walks and I am likely to encounter with the upper end loads I have chosen.

Keep It Fun!

Bob Baker of Freedom Arms performed all the test shooting in arriving at the data for the .500 Wyoming Express and said, “I’m getting too old for this stuff!” If he is getting too old, I am way beyond it! There’s no doubt this cartridge, especially in full-house loadings, kicks and kicks hard. Baker says “Power is useless if the shooter can’t control the firearm.” Therefore start out with lower velocity loads to learn how to handle the recoil of the revolver, which can be abusive. As a level of comfort and skill is achieved, the load can be increased accordingly.

The upper-end loads should be used only by those experienced with and capable of handling big-bore, high-power handguns and even then should be shot sparingly. In other words, keep it fun to shoot. That is sound advice.

For me “fun loads” in the 43⁄4″ Perfect Packin’ Pistol are in the 900 to 1,000 fps range. After this the recoil is more than I care to experience on a regular basis. Not only are these loads much more pleasurable to shoot, a 400- to 440-grain bullet at 900 fps will go all the way through any deer. These loads have also proven to be exceptionally accurate in the short-barreled Perfect Packin’ Pistol. I will purchase this test sixgun from Freedom Arms and it will join my 43⁄4″ .454 and .475 Linebaugh Model 83s to form a Perfect Packin’ Pistol Trio.

Loading Up

Once the resizing die is set properly the .500 Wyoming Express is as easy to load for as any straight-walled pistol cartridge. Rifle primers are used in the .500 WE and I had to put a new mainspring in my 71⁄2″ Model 83. The original mainspring was fine with .50

AE loads with pistol primers, but it was too weak to consistently ignite the CCI 200 rifle primers.

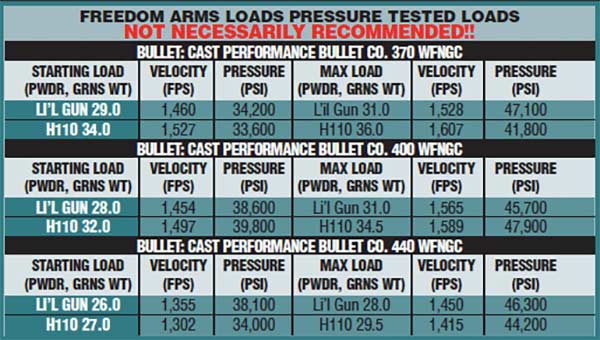

Powder selection for the .500 Wyoming Express includes Hodgdon’s Trail Boss for loads around 800 fps. For the 900 to 1,100 fps loads, I used Hodgdon’s TiteGroup, HS6, H4427 and Long Shot, Winchester 231, and Alliant Blue Dot. Full-power loads should only be assembled with Hodgdon’s H4227, H110, Li’l Gun or Winchester’s W296.

Although a wide variety of bullets are not available, those we have are excellent. These include a 370-grain HCGC (Hard Cast Gas Check) from Oregon Trail; 370, 400, and 440 HCGCs from Cast Performance Bullet Company and Sierra jacketed bullets in a 350 JHP and 400 JFN. A caution in using the Sierra bullets, if they are loaded by crimping in the middle of the cannelure they are too long for the Freedom Arms cylinder and enough so to keep the cylinder from rotating. I have found by crimping at the top end of the cannelure they will clear the cylinder and the loads I use do not jump the crimp. However, if heavier loads are used, this may not be the case and brass should be trimmed back enough to allow room for the cylinder rotating even if the bullets move forward. Sierra will be offering these bullets with the cannelure set higher to allow for proper overall length with this cartridge in the Freedom Arms Model 83.

I have included some of my loading data as well as some top-end loads from Freedom Arms. This is a brand new cartridge and we are learning. Freedom Arms says of their loads, “These loads are for pressure reference only and are not recommended by Freedom Arms.” In other words be careful and especially pay attention to the “keep it fun” admonition.

MODEL 83

Maker: Freedom Arms Inc.

314 Highway 239, Freedom, Wyoming 83120

(307) 883-2468, www.freedomarms.com

ACTION TYPE: Single action revolver

CALIBER: .500 Wyoming Express

CAPACITY: 5

BARREL LENGTH: 43⁄4″, 6″, 71⁄2″

OVERALL LENGTH: 71⁄2″ Model 13″

WEIGHT: 2.98 pounds (43⁄4″), 2.99 pounds (6″), 3.19 pounds (71⁄2″)

FINISH: Stainless Steel Brushed (Premium Grade) or Matte (Field Grade)

SIGHTS: Adjustable Rear and Interchangeable Ramp Front

GRIPS: Winewood (Premier

Grade), Pachmayr rubber (Field Grade)

Get More Revolver Content Every Week!

Sign up for the Wheelgun Wednesday newsletter here: