0

Just a Little Squeeze

Interchangeable Choke Tubes Are The

Biggest Game Changer Since The Shotshell

Interchangeable choke tubes have been one of shotgunning’s greatest advancements. While the concept of a choking a shotgun bore dates back to the latter half of the 18th century, the idea of a detachable tube didn’t appear until April 1866, when American gunsmith Sylvester H. Roper patented an external choke tube that was threaded onto the muzzle of his unique revolving shotgun. That idea seemed to die out for almost a century until its revival in the form of the externally mounted Poly-Choke, Cutts Compensator and Mossberg’s C-Lect-Choke systems, but their application was severely limited to the single barrel tube.

Whether they’re labeled flush, extended, ported or breaching, today’s internally mounted, detachable choke tubes have revolutionized the shotgun game. Never before have competitors or hunters had greater control over the performance of their smoothbores. Never before has one shotgun been able to fill so many different roles. It still takes some time at the patterning board to determine exactly what the right degree of choke is for the load being shot, but it’s time well spent and an education in itself.

What is choke in terms of choke tubes? The degree of choke is determined—and measured—as the difference in diameter between the main bore and the tightest portion of the choke constriction.

But here’s the kicker: With many modern barrels being overbored, choke tubes for various makes of shotguns will exhibit different degrees of constriction while providing the same degree of choke.

But here’s the kicker: With many modern barrels being overbored, choke tubes for various makes of shotguns will exhibit different degrees of constriction while providing the same degree of choke.

However, choke tubes can be described as having a specific degree of constriction. In this regard, both domestic and foreign makers share a similar set of dimensions, whether they are in inch or millimeter measurements.

What’s remarkable about these constrictions is how subtle they are, yet how influential they are on the shot pattern. For example, the difference between Improved Cylinder and Modified is 0.010-inches. That’s the thickness of just 4 pages of a GUNS magazine. The difference between Modified and Full is the thickness of just 9 pages.

Going back to the idea that choke is the difference between nominal bore size and choke constriction, here’s a practical example. The traditional bore diameter of a 12-gauge has been 0.729 to 0.730 inches. The nominal bore diameter of a backbored, 12-gauge Browning shotgun that accepts Invector Plus choke tubes is 0.742 inches. Thus, an Improved Modified tube for the Browning might measure 0.715-inches while that for a standard bore might measure 0.700-inches.

But steel shot really throws a monkey wrench into the gears. Being much harder than lead, steel calls for a different selection of chokes. When you’re hunkered down in a duck blind shooting steel, what we knew as a Skeet choke for lead morphs into a Modified for steel, a lead Improved Cylinder becomes a steel Modified and a lead Modified becomes a steel Full. Stick with Bismuth and you won’t have to worry about such things.

So What Does A Choke Tube Really Do?

Visualize a column of shot flying down a uniform diameter bore. The column has achieved a certain diameter and length. Then the column is squeezed down in the choke constriction. The outer layers of shot are accelerated and compressed inward. The diameter of the shot column is decreased and its length increased. The compression exerted by the outer layers helps to hold the shot column together once it slams into the atmosphere.

Less appreciated is the fact the constriction of choke retards the over-powder wad or shot tube (or cup) so the shot column is less affected by the trailing wad once it leaves the muzzle.

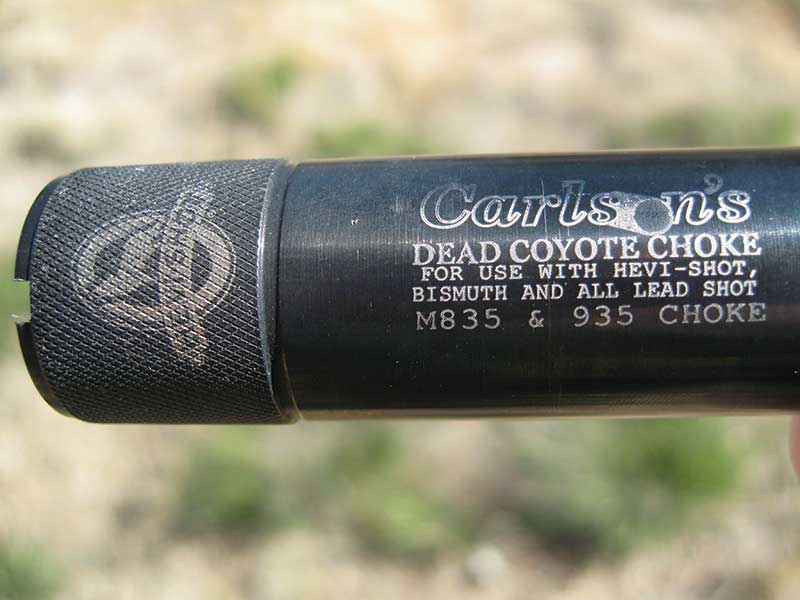

Today you can just about find a choke tube for any possible application and for any shotgun with a threaded barrel from a host of custom choke tube manufacturers. There are choke tubes for specific ammunition types like Hevi-Shot, ATK’s Black Cloud, Winchester’s Long Beard, Rooster XR, buckshot and rifled slugs. There are specialized tubes for turkey, waterfowl, predator, upland birds and deer. There are tubes for trap, skeet, sporting clays and card target competition. There are choke tubes for law enforcement and home defense. You can even find an adjustable Poly-Choke tube that threads into the barrel.

Choke tubes must be handled carefully. They’re thin and delicate, and their thread forms are fine indeed. Keep them separated by shotgun brand and gauge. Store them in individual, protective plastic tubes inside a specialized tube case of some sort. Keep them clean and always lubricate their fine threads and tube bodies with a dollop of an anti-seize compound like Birchwood Casey’s Choke Tube Lube Grease.

The fun is in experimenting with many of the new tubes out there. Ever heard of a “Light Modified” choke with a 0.715-inch constriction? It may be the most all-around useful tube ever developed for hunting and clays.

At the other end of the spectrum are the Super Full tubes with 0.665 to 0.675-inch constrictions for predator hunting with hard, non-toxics like Hevi-Shot.

The choke is a fascinating subject, and knowledge of the subject translates directly into more game harvested in the field and more clays dusted on the range.

Tale Of The Micrometer

Here are the commonly accepted ideal parameters for chokes expressed in thousands-of-an-inch as well as in the efficiency of the choke to deliver a percentage of the shot charge into a 30-inch circle at 40 yards:

True Cylinder: 0.000-inch constriction (25 to 30 percent)

Skeet: 0.005-inch constriction (25 to 30 percent)

Imp.Cylinder: 0.010-inch constriction (35 to 40 percent)

Modified: 0.020-inch constriction (45 to 55 percent)

Imp. Modified:0.030-inch constriction (55 to 65 percent)

Full: 0.040-inch constriction (65 to 75 percent)

Where to Get Choked Up

Briley Manufacturing

1230 Lumpkin Rd.,

Houston, TX 77043

(800) 331-5718

www.briley.com

Carlson’s Choke Tubes

720 S. Second St.

P.O. Box 162

Atwood, KS 67730

(785) 626-3700

Colonial Choke and Tool

11390 Hwy 31 Unit 4

Spanish Fort, AL 36527

(251) 626-3100,

Kick’s Industries, Comp-N-Choke

925 Waynesboro Hwy.

Sylvania, GA 30467

(800) 587-2779

Poly-Choke

322 N. Military Rd.,

Fond du Lac, WI 54935

(920) 929-0667

Trulock Tool

PO Box 530

Whingham , GA 39897

(229) 762-4678