In order to get any sort of accuracy from my two .44-77’s I have to cast bullets of a very soft alloy—say one part tin to 40 parts pure lead. The explosion of black powder upon ignition bumps up the soft bullets to fill the barrel. In fact I keep one electric lead furnace just with that alloy. It also works well with .38 and .41 Colt rounds.

Speaking of casting bullets, I’ve done that as a handloader since day one. In fact in the home area of my youth—Mingo County, West Virginia—there was no other source of bullets when I began reloading in 1966. There are plenty of bullets around for nigh-on everything nowadays, but I personally remain stuck in the bullet casting era and enjoy it. Many consider it an onerous chore but I treasure time spent casting as relaxing. Of the 50+ cartridges I reload currently, there are only five for which I do not have bullet molds. They are .223 Remington, .222 Remington Magnum, 6.5mm Italian Carcano, 7.62x39mm and 7.92x33mm Kurz.

In the first 20 years of my reloading career I put together perhaps 100 rounds with black powder as propellant. Those were .45-70’s for an original Trapdoor Springfield carbine. Now I load black powder to the tune of about a 25-pound case every year. The igniting spark was the game of NRA Black Powder Cartridge Rifle Silhouette. I’m one of the game’s oldest competitors and from over 25 years of experimentation I know for sure that with 1870’s vintage rifles (or replicas), black powder gives the very best long-range accuracy in cartridges originally designed for it.

A Most Pressing Pastime

Handloading As A High-Volume Hobby

Recently, by consulting various reloading manuals and research books, I determined in my 48 years of handloading, I’ve put together loads for at least 125 different cartridges. They have ranged from .17 Remington to .50-90 Sharps in rifles and from .32 ACP to .454 Casull in handguns. Total numbers have ranged from a few dozen .17 Remingtons to scores of some handgun rounds. For instance, I quit counting .38 Specials after 60,000 and that was back in 1980. Currently I own firearms chambered for over 50 cartridges, all of which I handload for, except .22 rimfires.

Probably the most common (or popular) cartridges I’ve loaded have been those .38 Specials in handguns and .30-06 in rifles. The most unusual ones are likely the 9mm Japanese Revolver or the French 7.65mm Long in handguns. In rifles my most oddball ones have been the Hungarian 8x56mmR and .50-2-inch Sharps. Perhaps surprising is the fact that I’ve never reloaded a single shotgun shell.

Sometimes a certain cartridge is handloader friendly to an amazing degree, meaning almost any load combination from various reloading manuals shoot adequately. Not surprising is those same ones are among the most commonly reloaded. Good examples there are again .38 Specials and .30-06 but I think others like .223 Remington and .308 Winchester should be included. Although it is not so common the .41 Magnum is another “easy” one.

Some cartridges present considerable difficulties. Consider the .41 Colt. It is not just a “little brother” to the .41 Magnum. Colt built their .41 Colt barrels to have 0.401- to 0.402-inch groove diameters. (Source: Original Colt barrel spec sheet dated 1922). By the 1890’s, however, the ammunition factories loaded .41 Colts with 0.386-inch bullets but gave them a hollowbase so they would expand and grip the rifling. The same situation existed with .38 Colt but change barrel groove diameter to 0.375-inch and factory bullet diameter to 0.357.

The .44-77 can be another stinker—depending on the exact rifle. Back in its heyday in the 1870’s, Sharps and Remington rifle barrels were usually 0.451-inch in their grooves. In fact, both my original Sharps ’74 and Remington No. 1 rolling block measure that. That being said, I’ve measured original Sharps Model 1874’s with groove diameters as tight as 0.446-inch and as large as 0.457-inch. The single original .44-77 cartridge in my collection has a paper-patched bullet of 0.444-inch diameter.

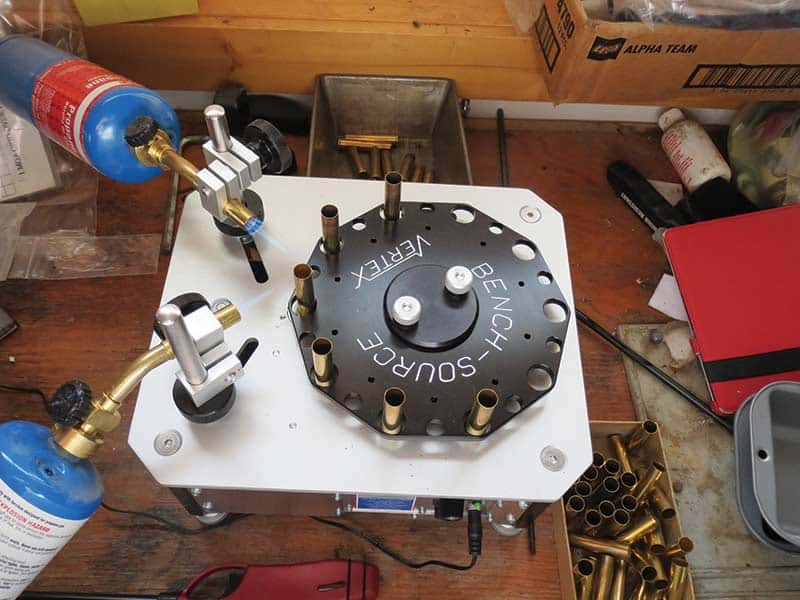

In regards to handgun and rifle reloading I’ve tried all ancillary facets. Those include outside neck turning cases for a benchrest rifle, forming cases so as to have brass for obsolete calibers, inside neck reaming so those formed cases will chamber in antique rifles, annealing cases to soften their necks, trimming cases that grow too long and much more. My least favorite chore is trimming, but an electric Lyman trimmer has helped with that for 30 years. An equally “least favorite” chore would be case annealing, but specific machines for that have made it almost pleasant.

I keep four reloading presses mounted at all times. One is a single stage RCBS, another is a turret Redding and two are progressives by Dillon. Also I keep three Lyman lube/sizing machines and have 45 sizing dies for different diameters from 0.225 to 0.580 inches. (I used to cast for .22 centerfires and the .58 die is for a replica Civil War musket.)

For many years, I’ve bragged that when at home, and left to my own devices, I simply can never get bored.

My all-consuming passion for reloading ensures that.

Bench-Source

8341 Industrial Drive

Olive Branch, MS 38654

(662) 895-0803

www.bench-source.com