Monster Maximum Magnum

Big Bore Quartet: The S&W .500

In the 1970s Elgin Gates, who served many years as head of IHMSA (International Handgun Metallic Silhouette Association), looked at the lineup of Magnums, decided longer would be better, and designed a series of new Magnum cartridges. All the new cartridges were dubbed SuperMags by Gates and were 1.610″ in length, or about three-tenths of an inch longer than standard Magnum cartridges, requiring the production of a totally new revolver with a longer frame and cylinder. At the time Gates made up SuperMag cartridges in .357, .375, .44, .45, .50, and .60 calibers.

The SuperMag series of cartridges did become a reality in the 1980’s through the co-operation of Gates and stretch both frame and cylinder to begin the chambering of Gates’ SuperMag cartridges. The SuperMags were designed as long range silhouette sixguns, and they would never have seen the light of day had it not been for the rapid rise of silhouette shooting in the early 1980s. The three standard Magnum cartridges, .357, .41, and .44, were wonderfully accurate, but the idea for the SuperMags was to allow the use of longer brass to increase velocity, lower the trajectory arc and increase the knockdown power, especially on the 200 meter, 60-pound steel rams.

The .357 SuperMag was eagerly accepted by silhouetters at the same time it was being trashed by some of my fellow gunwriters. Many of these writers did not understand silhouetting nor did they understand the reason for the .357 SuperMag and tried to bury it before it had a chance to prove itself with proper use. The .357 SuperMag was not designed to see how fast one could drive lightweight .357 Magnum bullets from a revolver barrel, but to give .357 Magnum velocities to heavyweight bullets. This was accomplished by stretching both cartridge case and cylinders. The second in the SuperMag series, the .375 SuperMag, like its smaller counterpart, was 1.610″ in length and cartridges originally had to be made from .375 Winchester or .30-30 Winchester brass.

When the .357 SuperMag from Dan Wesson first appeared on the scene, more than one wildcatter was waiting to turn it into a true Dan Wesson Arms. Dan Wesson was already producing sixguns with standard sized frames and cylinders in .357, .41, and .44 Magnum when they decided to big bore. The largest number of these were turned into .44 SuperMags, and I had the privilege of doing extensive shooting of one such early wildcat, the .44 UltraMag created by Lew Schafer. The .44 UltraMag used .444 Marlin brass cut to 1.600″. The .444 brass, being larger in diameter than .44 Magnum brass, was swaged and turned on a lathe until it matched .44 Magnum dimensions. The reason, of course, was to also allow the use of the shorter .44 Magnums in the same cylinder. Various .44 Super-Mags, based on either the .444 Marlin or .30-40 Krag surfaced and the “.44 Stretched Magnum” became a production sixgun in 1988. Again, Dan Wesson Arms and Elgin Gates combined forces to create the .445 SuperMag. Dan Wesson supplied the guns and IHMSA supplied the brass. Shortly before the old Dan Wesson factory closed, a few .41 SuperMags were offered and these are now a standard production item with the new Wesson Firearms.

Meanwhile over at Sturm Ruger, the .357 SuperMag arrived as the .357 Maximum in the wonderfully accurate, stretched frame Super Blackhawk. Originally offered with a 101⁄2″ barrel, this was the most accurate revolver I had ever experienced until I encountered the Freedom Arms sixguns. Less than 10,000 .357 Maximums were produced in 1983 and ’84 when Ruger pulled them from the production line. There were complaints of gas cutting on the bottom of the top strap and throat erosion — again by those who did not understand the cartridge and were using the wrong type of ammunition.

John Linebaugh, who had been building custom five-shot Rugers with Bisley grip frames chambered in his .475 and .500 Linebaugh cartridges took a look at the stretched frame Ruger single actions and came up with his two Maximum cartridges, the .475 and .500 Linebaugh Longs. His original cartridges used .45-70 and .348 Winchester brass respectively trimmed to 1.300″. He now used the same brass trimmed to 1.610″ to create his new cartridges. The stretched .500 used 380- to 440-grain hard-cast bullets sized to .511″. With full-house loads, a custom Bisley Blackhawk chambered in any of the Linebaugh cartridges weighs just slightly more than three pounds making it easy to pack. However, recoil is exceptionally heavy.

That brings us to the present. Smith & Wesson, the company that brought us the .357 Magnum in 1935 followed by the .44 Magnum and .41 Magnum in 1955 and 1964 respectively, has now introduced the most powerful standard production sixgun cartridge ever offered in the largest revolver they have ever produced. In the past century plus a couple years, Smith & Wesson has offered the K- , N-, I-, J-, and L-frames. The Xframe Smith is a five-shot, 4 1⁄2- pound stainless steel Model 500 chambered in the .500 S&W Magnum. The brass, produced by Starline, is 1.625″ long instead of the 1.610″ used by Linebaugh, and this cartridge uses true 50-caliber bullets at .500″ instead of the .511″ used in the custom .500s.

Full-house loads for the .500 S&W Magnum feature 440-grain Cast Performance Bullet Co. hard-cast, gas-checked bullets with a muzzle velocity of 1,600+ fps from an 8 3/8″ Model 500. Both Buffalo Bore and Cor-Bon offer these loads. As this is written, Buffalo Bore also offers a lighter load with the same bullet at 1,300+ fps, while Cor-Bon also has a 275-grain Barnes XDB rated at 1,665 fps and a 400-grain jacketed flatpoint at 1,675 fps. The relatively lightweight 275- grain Barnes load is easily manageable, however the full house 400- and 440- grain loads produce very heavy, that is H-E-A-V-Y recoil.

It has been my pleasure (?) to spend several weeks test-firing four separate and distinct handguns chambered for the .500 S&W Magnum. All of the factory loads have been tested as well as handloads assembled with Starline brass, CCI 350 Magnum Pistol Primers, and bullets from BRP, CPBC, and Barnes Bullets. With one double-action revolver, two single-action sixguns, and one single-shot pistol, at no time did I encounter hard extraction with any loads and, in fact, all five cartridges extracted simultaneously and easily from the S&W Model 500 with all loads fired.

Smith & Wesson 500

The S&W Model 500 with its heavy, underlugged barrel looks like an oversized S&W N-frame. One doesn’t have to pick one up to know it is larger and heavier as it has a distinctly massive look to it. Even with its large size and heavy weight it is not as ungainly as one might expect. It certainly is not something most folks would want to carry in a hip holster. The sights on the Model 500 are excellent being a S&W fully adjustable rear mated up with a post front on a ramp base. Both sights are black and easy to see, however when the rear sight is bottomed out, my point of impact is 2″ to 3″ high at 25 yards.

The huge five-shot cylinder is locked at the rear in normal S&W fashion with a cylinder release latch below the hammer on the left side of frame, and also a ball detent at the front of frame, which matches up with a recess in the yoke. The barrel has a 1:18 twist with a full-length serrated rib along the top and a recoil reducing muzzlebrake in front of the front sight. It is marked on the right side, “SMITH & WESSON”, while the right side contains “500 S&W MAGNUM.” The model number is found in large letters on the side plate. Hammer and trigger are both the wide target style. The hammer is checkered for easier cocking, while someone did an excellent job in smoothing out the trigger with no sharp edges. The singleaction trigger pull is a creep-free four pounds. I’m no big fan of rubber grips especially those with finger grooves. However, the rubber grips on the Model 500 are highly functional with finger grooves that actually fit my fingers, and a wide, cushioned area on the backstrap directly below the hammer. When the hammer falls on a full-house load the cushion is deeply appreciated.

Magnum Research BFR

Magnum Research’s offering in .500 S&W Magnum is the BFR revolver. The basic platform of the .500 is the long cylindered .45-70 re-chambered and fitted with a 1:15 twist 101⁄2″ barrel. Magnum Research uses hand-lapped barrels with cut rifling. At the front is a recessed crown, while at the back end, barrel/cylinder gaps are held under .005″. The huge five-shot cylinder is free-spinning, which means it can be rotated clockwise or counterclockwise for loading or unloading. With the .500 Magnum being much shorter than the .45-70, the bullet has a long way to travel through the cylinder throat, into the forcing cone and down the barrel. It certainly did not seem to affect the accuracy in any way.

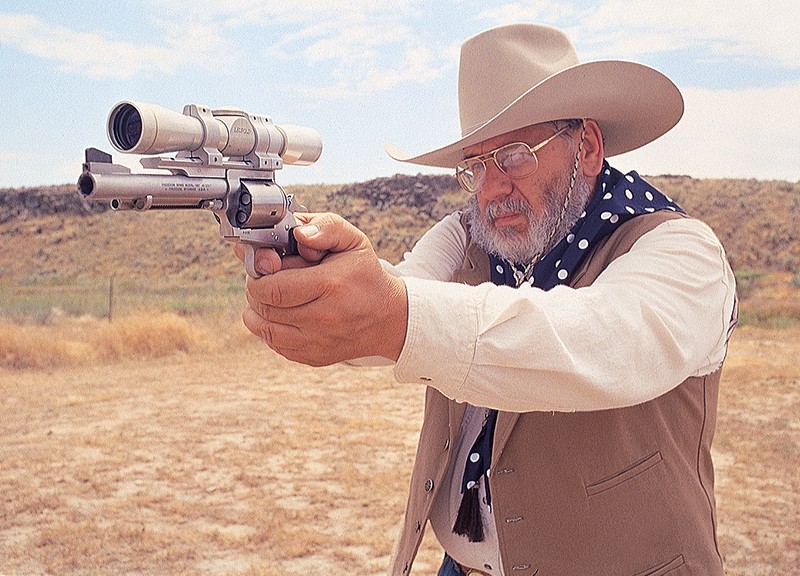

The BFR is constructed of stainless steel, with a soft, brushed finish. The grip frame is much like Ruger’s Super Blackhawk and fitted with wraparound rubber grips which were once again much appreciated when firing full-house loads. The BFR features a fully adjustable rear sight mated up with a ramp front sight, however I ordered the test gun with a 2X Leupold LER pistol scope on an SSK base. It was not uncommon to have groups fired with the BFR .500 S&W Magnum be well under 1″ at 25 yards. With the milder loads, and no anticipation of heavy recoil, some loads were in the 1/2″ range.

Thompson Center Encore

From revolvers we go to Thompson Center’s Encore. This break-open, singleshot pistol is operated by pressing backwards on the tang below the triggerguard, allowing the barrel to tip forward for loading or unloading the chamber. After closing, the Encore is ready for action. The Encore solves the problem of whether or not the safety is engaged by incorporating a hammer rebounding safety. There are no levers to push on or off. When the action is closed the hammer rebounds to a safe position and the gun will not fire unless the hammer is cocked. If one decides not to fire, the hammer is let down carefully and the hammer automatically rebounds to safe position. When one is ready to shoot it is only necessary to re-cock the hammer. Both the safety operation and the lack of having to re-cock the action makes for a much simpler operation especially in a hunting situation.

SSK has been using the Encore for wildcat chamberings for several years including such potent performers as the .30/06 JDJ with a 150-grain bullet at 2,900 fps, the .338/06 JDJ with a 200-grain bullet at 2,700 fps, and the .375/06 JDJ using a 270-grain bullet at 2,400 fps. All of these are on the .30-06 case. SSK has also chambered the Encore for the .454 Casull and now offers a custom Encore in .500 S&W.

When I called J.D. Jones at SSK to see about getting a test .500 Encore, he related he would be happy to send me his original prototype even though it was not picture perfect pretty. That was fine with me and the Encore pictured has an unmatched forearm of wood and a rubber grip. I would not even think of shooting this Encore with top-end loads without the finger-grooved rubber grip. The SSK muzzlebrake is also most welcome when shooting full-power loads.

Since starting this I have had the opportunity to hunt with the SSK Encore .500 using Cor-Bon’s 275-grain Barnes load. Results were dramatic and very conclusive. Two large Catalina Goats were taken at 50 to 75 yards. Both bullets entered on the point of the shoulder, both animals dropped immediately at the shot, and penetration was complete. One bullet was found in the dirt on the other side perfectly mushroomed. This bullet and load should be excellent for deer and deer-sized game.

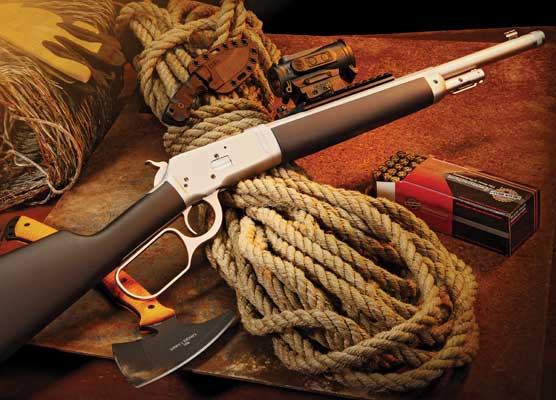

Reeder Ultimate 500

The final test .500 in this quartet of Monster Maximum Magnums comes from Gary Reeder Custom Guns. This is also a prototype built on a Reeder stretched frame. It has been fitted with an 81⁄2″ barrel with a deeply recessed muzzle crown. The grip frame, hammer and trigger are all Bisley Model with all sharp edges removed from the grip and also the trigger. Sights are a V-notch rear matched up with a gold bead on a flat post.

The finish is satin stainless steel with a highly polished hammer, trigger, and ejector rod head. The grip-frame screws are Allen-style and the cylinder base pin has a large knurled head and it is locked in place by an Allen screw. This sixgun, as are all .500s, is designed for hunting. To accentuate this fact, the cylinder is engraved with a bull elephant on one side and a bull elk on the other. Engraving on the left side of the barrel identifies this custom gun as the “Gary Reeder Ultimate 500.”

This sixgun was designed for easy packing rather than easy shooting with full-house loads. In a hunting situation I do not recognize recoil. However, when doing extensive shooting I certainly do. One heavy load with a 440-grain hard cast at 1,300+ fps was plenty for me. I was more than happy to spend my time shooting more pleasant loads. This sixgun will handle heavy loads all day; I can’t.

The .357 Magnum and .44 Magnum filled a niche at the right time. The .41 Magnum was supposed to but has never quite made it. The .500? It will make its own.

Get More Revolver Content Every Week!

Sign up for the Wheelgun Wednesday newsletter here: