Dovetail DIY

There Are Several Ways to Install Pistol Sights — Then There's The Right Way

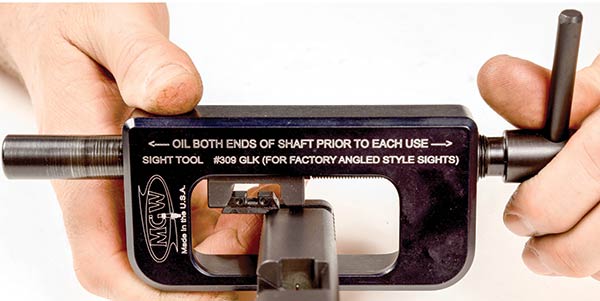

Installing and adjusting dovetail sights is simple if you have the proper tools. Manufacturers such as MGW make universal or model-specific sight tools.

Once the sight correctly starts into the groove, use a sight adjustment tool to push the sight into its final centered position.

It’s alarming to see some of the home-brewed “gunsmithing techniques” we come across on the Internet and various social media channels. Many might seem to be able to get the job done, but would never withstand real-world application.

Others make it happen, but at the risk of aesthetically or functionally damaging the firearm in some way. In short, the School of Sledgehammer and Chisel Gunsmithing is alive and well, leading those seeking enlightenment down a dark and sometimes expensive path. The installation of dovetail-mount sights on a pistol slide is a case in point.

Aftermarket sights are arguably the first modification most pistols receive, the intention being to improve low-light aiming by installing light-gathering fiber optic or glow-in-the-dark tritium units. The effectiveness of high-visibility sights often depends on your shooting style, but for personal defense or duty applications, we’ve yet to see a tactical-type pistol that didn’t beg for low-light sights.

Just for kicks we took a stroll through our search engine results, looking to see how some folks go about telling the rest of the world how to install dovetail pistol sights. The very first video return had a fellow mangling a 1911 rear sight with a file, cutting it so loose it pushed through the slide’s dovetail slot with hand pressure only. His “fix”? Secure it with a big glob of epoxy.

Left: To ensure center alignment, use a ruler to measure the edge of the sight base to the edge of the dovetail groove. When both sides measure the same distance, the installation is complete. Middle: Installing a front sight on a GLOCK slide is also a simple matter if you have the proper screw-on sight tool. Right: A correctly-sized sight for a GLOCK should push no more than 1/3 of the way into the dovetail groove by hand. If it’s too tight, minor filing of the base is required using a flat file.

Sheesh

Dovetail mounting has a long history, going back to the early muzzleloader days and continuing with the top-end handguns of today. The reason is the dovetail is a simple sight-mounting system. It works great as designed to keep sights secure and correctly aligned. This is an interference-fit system ensuring nothing will come loose (when correctly installed) during the rigors of use. The problem with dovetail sights comes when tinkerers attempt to remove and replace them without the proper tools or without an understanding of the proper techniques involved.

Being an interference-fit system between the sight’s dovetail and the gun’s dovetail groove requires relatively significant mechanical pressure be applied for the sights to be removed, installed, or adjusted to proper alignment — and to stay that way. Yes, you can do it all with a hammer, file and some form of punch, but this approach risks damaging the sight, the slide, and makes minute sight adjustments much more difficult than they need to be.

There is a simple, elegant solution to this — get the proper tool.

There are a few manufacturers who make rock-solid sight installation tools covering all the major brands. Some are model-specific while others are universal in design. In either case, these tools represent a significant investment but one many gun owners are loath to make.

That’s a pity, because favored gun brands are like those scrumptious potato chips; You can’t have just one, and it only takes a couple of trips to a gunsmith for sight installation to pay for a quality sight tool.

So, if you’re a 1911, Beretta 92 or GLOCK fan, a proper sight tool is ultimately a cost-saving element of your workbench. Aside from removing and installing sights, a sight tool also gives you the ability to make alignment adjustments if your point-of-impact is not quite where you want it to be.

MGW Armory, mgwarmory.com

https://mgwarmory.com/