The year 1873 saw Colt introduce the Single Action Army in .45 Colt and Winchester upgrade the Yellow Boy to the Model of 1873, chambered in the equally new .44 WCF. It didn’t take long for someone to figure out it would be great to carry a sixgun and levergun chambered for the same cartridge. Beginning in 1878 it was possible to have a Winchester and a Colt SAA both chambered in .44-40.

However, Winchester soon necked the .44-40 to .40 caliber and the .38-40 was born. The .38-40 isn’t really a .38 caliber but actually a .40 (.400-.401-diameter bullets)!

At first called the .38 WCF, the new load was Winchester’s way of offering a faster, flatter shooting cartridge than the .44-40. The Winchester M73 was first chambered in .38-40 in 1880 with the same chambering following in the Colt SAA in the mid-1880s.

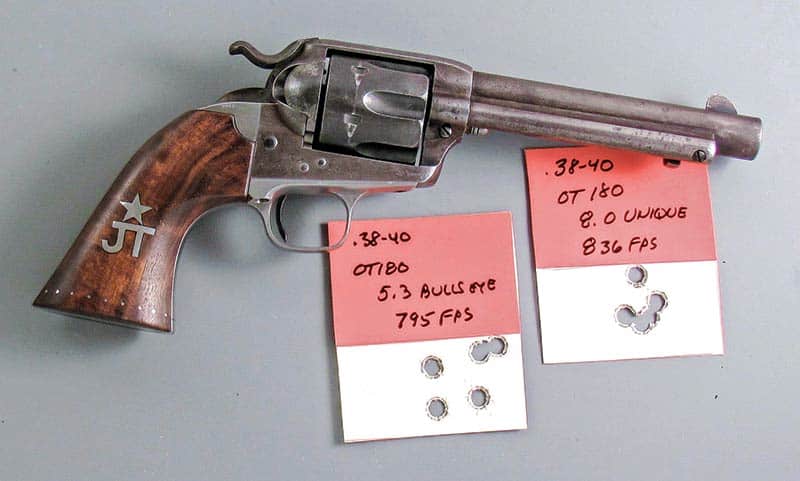

I’ll always have a special spot in my heart for the .38-40 as in 1957 I purchased my first centerfire single action — a beautiful, turn-of-the-century, 4-3/4″ Colt SAA so chambered.

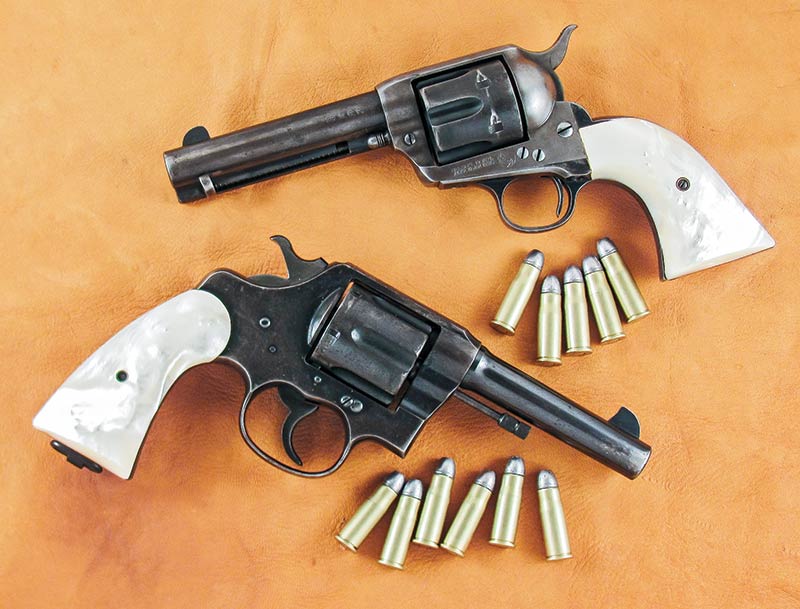

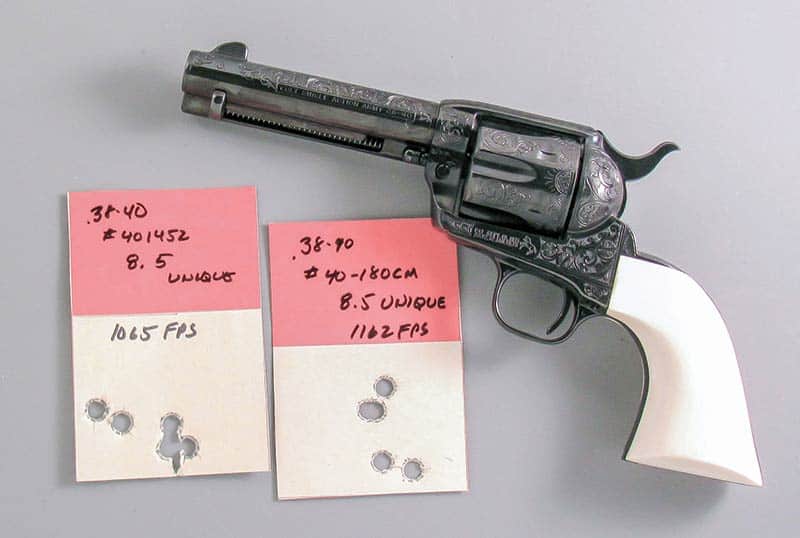

If the world was perfect I could tell you I still own it, but in the stupidity of youth I allowed it to get away from me. As a consolation it has since been replaced many times over with several fine .38-40s, including a 3rd Generation 4-3/4″ SAA, a pair of 7-1/2″ Model Ps (one Colt, one from USFA), and I’ve even found a couple Colt New Service .38 WCFs.

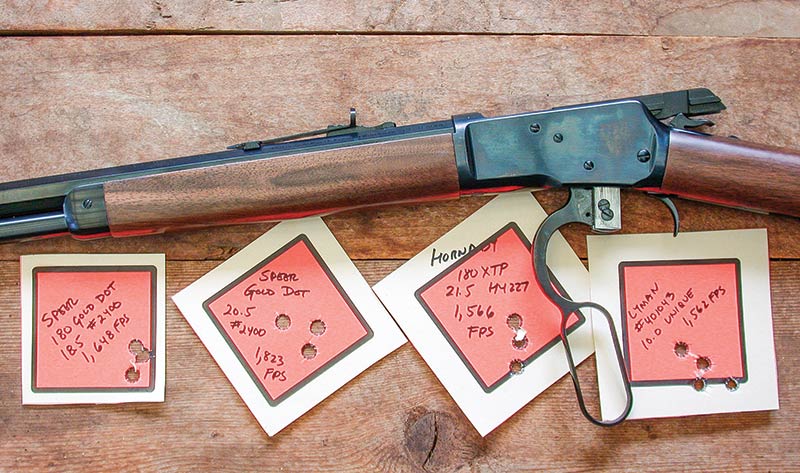

Levergun-wise there is a Cimarron 1873 Carbine, an original Winchester Model 92 plus a newer “Miroku Winchester” with an octagon barrel. Along the line I’ve also picked up Italian-made replica .38-40s in all three of the original barrel lengths. They leave nothing to be desired when it comes to accuracy, fit, and finish.

The .38-40 is the cartridge for those who wish to stay with authentic frontier loads but don’t want the recoil of a 255-gr. .45 Colt loaded to original levels (or even the lighter recoiling 200-gr. .44-40).

The .38-40, usually loaded with 180-gr. bullets, is very pleasant to shoot even with loads of 1,000 fps or more. The lighter weight bullets combined with the slightly heavier weight of the .38 WCF-chambered single action — be it Colt or replica — gives us a cartridge shooting both “hard and easy.”

As the old Texas Ranger told me: “These automatics they carry nowadays — they’s nothin’ to ’em, nothin’ at all. A .45 Colt is a good ’un, and the .44 too. But if you want a gun that shoots hard, get you a .38-40. Don’t kick much neither.”

The .38-40 — being a bottlenecked cartridge — precludes the use of conventional carbide sizing dies. This means the cases must be lubed before sizing but much of the work and bother of this step has now been removed by the use of spray-on lubes. For lubricating .38-40 brass I place about 100 clean cases in a shallow cardboard box, spray a little lube, shake, spray again, and they’re ready to go. Thus prepared the cases are ready to be loaded and there’s no reason why you can’t use a progressive press.

For most of my .38-40 loading, I go with RCBS’s Model 2000. All three of the most popular Colt SAA cartridges — .45 Colt, .44-40 and .38-40 — will work with the .45 Colt shell holder plate. On the RCBS 2000 the powder measure stays in place when changing from one cartridge to the next and all three of these work fine with the same powder charge of 8.0 grains of Unique. The RCBS die plate requires about 20 seconds to change from one caliber to another and I keep three of these handy, each holding die sets for the three mentioned cartridges.

Brass and Bullets