Stock Options?

The proper AR buffer tube is crucial

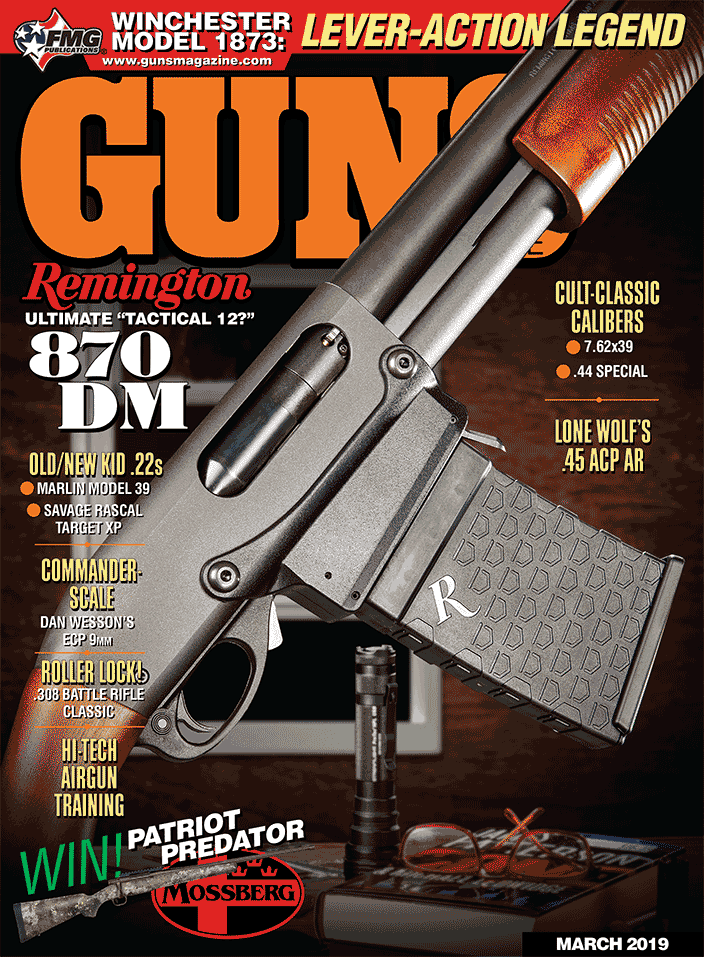

This is a B5 stock, Glen’s choice for his Geissele Automatics URGI because he claims the built-in compartment feels nice on his face!

When I get several questions on the same topic, I commence thinking: time to spool up a collective answer and share it here. I’ve based many a column on this premise and a few directly from readers’ letters so don’t be bashful!

This one comes from those looking to incorporate, upgrade or change a buttstock in the CAR-style collapsible format.

Now don’t roll your eyes because I’m going to make the obligatory obvious statement: The difference between a rifle and carbine receiver extension tube (some call it the “buffer tube”) is length. Well, of course it is. The carbine receiver extension tube is shorter to let the buttstock travel to its collapsed or fully-forward position.

If you’re shopping for a carbine stock, or already have one and want to change it, the first question you’ll need to answer (and usually the first question I get), is whether you need a “commercial” or “mil-spec” set.

The mil-spec is a smaller-diameter tube. As the tube and the stock must match up, a commercial-dimension stock will be loose on a mil-spec tube and a mil-spec stock won’t even fit onto a commercial tube.

Mil-spec (left) and commercial (right). The mil-spec tube is smaller and uses rolled threads while threads on the commercial version are cut.

Tale of Two Tubes

After Colt lost its patent on the AR-15 design there were a whopping lot of copies, a situation ultimately to our great benefit but not all were “as-good-as,” or “the-same-as.” This cost-cutting trend is pretty much the reason why the commercial-spec tube was born because the manufacturing process is cheaper.

Mil-spec tubes are impact-extruded and the end-cap is flat and integral. A true mil-spec tube is made from 7075 aluminum alloy while commercial versions are 6061. The higher-strength 7075 can be thinner-walled because the 6061 requires a thicker wall to make it equally strong. The threads on a mil-spec extension are rolled on (which is an extrusion process) while threads on a commercial model are cut like a water pipe. The commercial tube itself is likewise simply cut from 12-foot extrusions.

Minor machining and threading get done then a plug is welded to close the end. Keep in mind there are really no “standards” for commercial tubes as there are for mil-spec, which is, in its finest form, “mil-standard.” It’s common for a commercial tube to have an angled or slanted end though the tube is flat on the inside — the angle is purely cosmetic to match the stock angle. Clearly, the commercial manufacture method is faster, easier and less expensive.

The tube threads are the same (3-3 and 16-16 UN), meaning they’ll snug into any lower receiver but on mil-spec extension the threaded portion is a little larger diameter than the remainder of the tube body (inside diameters are the same). Mil-spec body diameter is 1.148″ and commercial is 1.168″. Measure the tube body, as implied, not the threads.

Rifle (top) and the carbine tubes are different length so the buffer and buffer spring need to match up properly or bad things happen!

Other differences usually include 7.80″ length instead of the standard 7.25″ for mil-spec. Be wary of commercial tubes posing as mil-spec!

What’s The Difference?

There’s no night-and-day difference in performance and commercial tubes are extremely likely to work just as well, for just as long, even though the threaded area on a mil-spec tube is stronger. Some jump up and down over this difference but I don’t hammer nails with my buttstock so its unlikely I’d break a commercial tube — plus, the mil-spec usually costs more.

The one major advantage of the mil-spec is some of the better stock designs are only done in mil-spec diameter which means more and better choices. I won’t tell you to retrofit a mil-spec if you already have a commercial but I sure would go mil-spec if starting fresh.

Rifle tubes are all the same dimensionally and they’re built from either 7075 or 6061 aluminum (I think 7075 is better). A steel tube is stronger for some of the adjustable-style stock pieces that clamp onto the tube itself and these are available aftermarket at a significant premium.

So, which one? I won’t go out on a limb and suggest any particular tube because there are many good ones and about a gazillion overall. They vary in details and features like battery storage compartments, sling attachment options and some even include magazine storage, a nice touch! Price is a leading indicator of quality. Look for something actually deployed as a mil-contract piece and you can’t go wrong.

What matters most is to know which tube you have so the fit is correct with the stock. I could have just finished at “mil-spec is a smaller-diameter tube” but then I couldn’t have used terms like “impact-extruded” and identified metals by numbers. These are the things I live for, people! These are some of my favorite things … Before I burst into song, go get a new stock!

The preceding is an adapted excerpt from Glen’s newest book, America’s Gun: The Practical AR15. Visit BuyZedikerBooks.com for more.

Geissele Automatics,

www.Geissele.com