The Technology

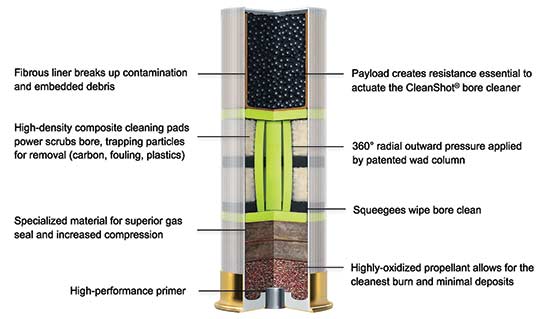

The image of the shell and Huntego’s explanations given for each stage and component of the new round are pretty self-explanatory. The CleanShot shell pictured is already protected by three US patents assigned to the inventor, Curt Whitworth of Michigan, with additional US and international patents pending. For the fun of it, I researched Whitworth’s patents. His patent, listed as US 9,212,879, is an interesting read.

The abstract states “A bore cleaning device is disclosed including a propellant providing a force to push the projectile down the bore of the firearm, a frame including a plurality of collapsible legs, and a cylindrically-shaped cleaning agent installed around the legs. The frame further includes a lower charge cap configured to receive the force of the propellant and a rigid front-end cap. The provided force creates a crushing force upon the frame. The crushing force causes the legs to collapse and provide an outward force upon the cleaning agent, wherein the outward force causes intimate contact between the cleaning agent and the bore as the device travels along the bore.”

Love that “intimate contact” bit! Who said patents are dry and boring?

The CleanShot shell, like all shotgun shells, is a system. The interior ballistics of a shotshell are among the most complex in ballistic science, and the CleanShot shell ranks right up there as an extremely complex system. Rifle and handgun ammo pale in comparison.

A shotshell is large and cylindrical and can be packed with a lot of interesting loads. It’s a system made up of a series of subsystems—a variety of case volumes, wads, primers, powders, shot and crimp styles—that must work in concert to deliver the charge within very strict, industry pressure criteria required by relatively weak-breeched shotguns. That’s exactly why shotshell reloading manuals repeatedly warn the handloader to “Never change any component of this listed load.”