Rifle Reloading Basics

"As It Turns Out..."

Have you been loading handgun cartridges but not bottleneck rifle cartridges because they seem more complex and require more equipment? I fully understand, having walked through the same scenario myself. My reloading setup came with extra stuff I never used, things like case trimmers and chamfer tools. My handgun cartridges never need any trimming and chamfering.

My physics college professor used the phrase “as it turns out” to explain things I thought were going to be complicated. Loading rifle cartridges is such a thing. You think it might be complicated but as it turns out it’s not, especially if you start with new or once-fired brass, which I recommend for your first ventures.

In The Beginning

Let’s walk through a project using factory new brass for one of my deer rifles, a .243 caliber Savage Axis II. We will load two types of bullets close to the same configuration I have in some factory ammo. This will allow me to compare loads for speed and accuracy. My rig is a Lee Precision Breech Lock Challenger Press, an affordable single stage press and I’m using Lee Reloading dies. The .243 die set has two resizing dies, one Full-Length Sizer and one Collett Neck Sizer, which is to be used for bolt action rifles with the brass coming from your gun only. Because I’m using new brass, no resizing is needed for this operation. I will mention if you’re using brass that has already been fired and needs more than just neck resizing, you will need case lube. I promise your brass will get stuck in the Full-Length Sizer if you don’t use case lube along with it.

Priming bottleneck cases can be done on the press. This is probably easier when you’re decapping used brass. Since I’m using new brass, I find it faster and easier to prime my brass using my RCBS 90200 Hand Priming Tool. If you don’t have an off-press primer, I suggest picking up a Lee Precision 90700, Auto Bench Priming Tool, available from Amazon for about $30. You can get a complete set of shell holders to go with it for another $17 and this will greatly speed up your priming operation whenever you’re using new brass.

Bullets

For my first .243 load, I’m using Lapua 90-gr. OTM Scenario bullets and Vihtavuori VN540 powder. The reloading data from the Vihtavuori 2020 Reloading Guide recommends a starting load of 34.9 grains and a maximum of 39.2. It just so happens the 34.9 grains corresponds with the 28.3 cc dipper in my Lee Precision 15 dipper powder measure kit. It always makes loading a powder charge easier. So it turns out the only die I’m using from my die set is the bullet seating die. With a little adjustment, I have the bullets seating so the overall length of the cartridge is the 2.638″ specified in the reloading chart. I measure this with a digital caliper. Running each of the cartridges through the Factory Crimp Die takes just a few minutes.

Loading Twins

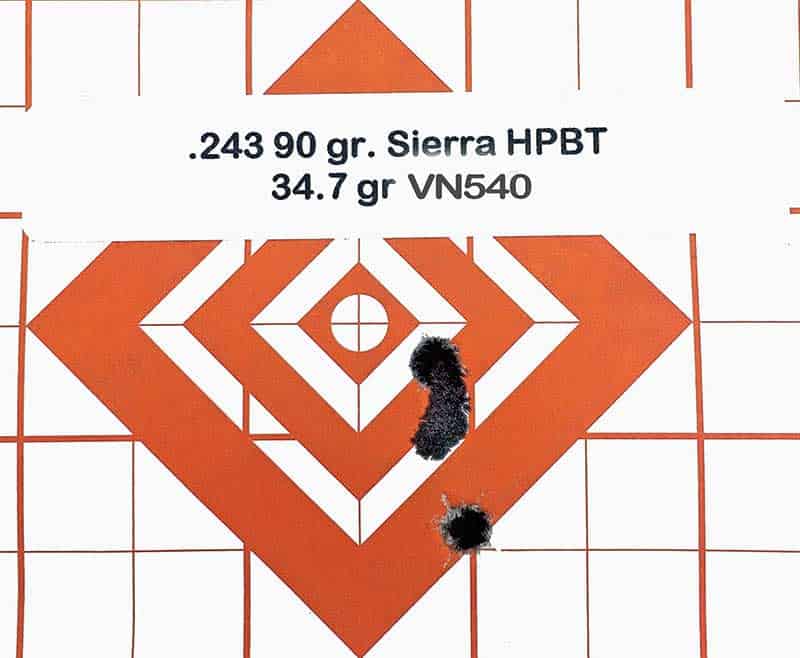

After loading 20 rounds with the Lapua Open Tip Match bullets, I load 20 more cartridges with a 90-gr. Sierra HPBT bullet. According to my reloading chart, the same powder charge is slightly above the minimum charge for this round so I continue to use the 28.3 cc dipper. The boat tail bullets drop into the case mouth easily and just a slight adjustment to the bullet seating die results in the 2.689″ max length for this load.

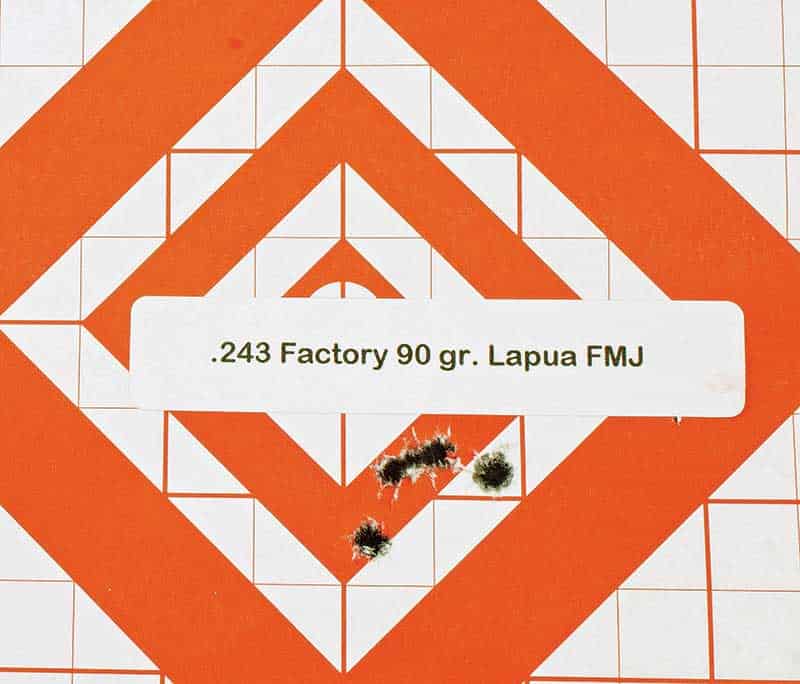

I’m hoping my handloads will perform just as well, if not better, than the Lapua factory rounds with a 90-gr. FMJ bullet. It’s more fun to take a deer with a cartridge you created yourself, don’t you think? With my scope dialed in at 50 yards using a sandbag rest, I fire five rounds of Lapua 90-gr. FMJ factory ammo through my chronometer into a test target. The factory rounds averaged 3,037 fps coming out of the barrel and created a nice 1.5″ grouping just below and to the right of dead center on the target.

The handloaded 90-gr. Lapua Open Tip Match bullets left the barrel at an average speed of 3,244 and impacted practically in the same target location with a slightly tighter group. The Sierra 90-gr. Hollow Point Boat Tail bullets averaged almost 200 fps faster velocity with four of the rounds impacting practically in the same hole and the fifth slightly below the cluster.

Results

The result of this exercise is two sets of handloaded cartridges fully ready for deer or hog hunting with my Savage Axis II XP rifle. As it turns out, reloading for the rifle, in this case was easier than loading handgun cartridges. When throwing in used brass, it’s a different game but it’s still not difficult. There are just some extra steps involved in preparing the brass, such as 1) inspecting the brass and throwing out any split or otherwise damaged cartridges, 2) trimming the case down to size and perhaps chamfering the opening, and 3) resizing the case as needed using a case lubricant, even if you’re using a carbide die.