If You Must Trim, Do It Quickly

Unfortunately, many handloaders prefer older cartridges with more sloping shoulders (perhaps because many shooters are older with more sloping shoulders). These rounds tend to stretch no matter how little we resize them. The standard trimming method involves putting the cases in a manual lathe-type trimmer and cranking away.

This method has three major flaws. First, blisters often form on your cranking fingers. Second, inserting the case into the shell-holder means taking it back out again, both requiring considerable time. Third, the slow cutting creates burrs both inside and outside the case mouth, requiring chamfering (yet another form of forced labor).

Many lathe trimmers can be fitted with a drill motor, not only preventing blisters but potentially increasing RPMs, preventing the dreaded burrs from forming around the case mouth. But the best of all worlds is case trimming without the lathe.

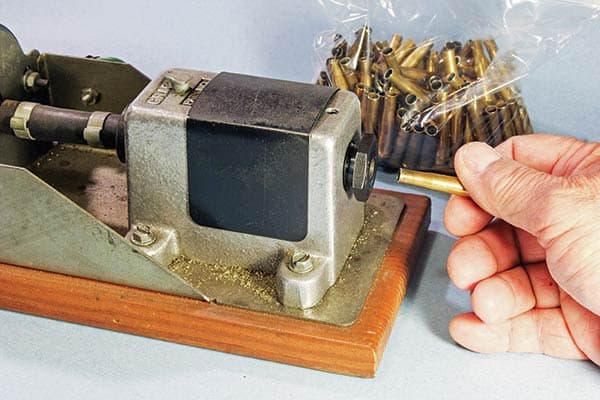

Instead of inserting the head of a case into a shell-holder or collet, then pushing a cutter into the case mouth, the neck and shoulder are inserted into a steel mirror-image of itself, where a rapidly-spinning blade trims the neck in a couple seconds. We then pull the case out and insert another, a much quicker process.

I own several power trimmers, one a lathe-type used for small batches. But when trimming more than 50 cases, I use one of several “front end” trimmers because even with a motor-powered lathe, trimming and chamfering more than 5 to 6 cases a minute is impossible. With an insertion trimmer 20 cases a minute is pretty easy, so I can trim the 1,000 empty cases for an upcoming prairie dog shoot in an hour.