SPARE PARTS

BEST HAVE SOME, AND SCHEDULE REPLACEMENT INTERVALS.

AR-15’s aren’t what I’d call high-maintenance, but if you’re a hard user there’s bound to be a need for a few parts replacements and function repairs. As a competitive shooter, I probably had a more paranoid viewpoint of what’s a “reasonable” fix-it kit to keep handy. I didn’t want to be helpless, or start scrounging, to get my gun back running after traveling to an overnight event. There are other venues where reliability is paramount, especially having the capacity to restore function to a non-functioning part. Let’s look at a few select parts to solve most common breakage-related issues.The very best spare is a complete bolt-carrier assembly! I pack one along for each tournament event or lengthy ammo testing session. This assembly has to have been tested for both function and zero. While it might seem like an extravagance, having a complete carrier assembly will, right quick-like and in a hurry, replace most parts most likely to be broken in the course of firing. If that’s too much (either real or perceived extravagance) then a tested bolt saves most days from ending early. A firing pin is easy enough to tote along. I have ruined a few of those during ammo testing sessions. If it pierces a primer, the flame will burn the metal, leaving the pin tip jagged.Any field repair kit really should include some means for lubrication and cleaning: a shop rag and small can of aerosol-wünder-oil lets you spritz away the grit. I use a fishing tackle box to carry my tools, spares and cleaning gear to the range.The level and nature of repairs you might be able to perform out in the field or on a tailgate, will depend on the tools—and of course parts—you’re willing to tote along, so let’s focus on what’s waiting back home.

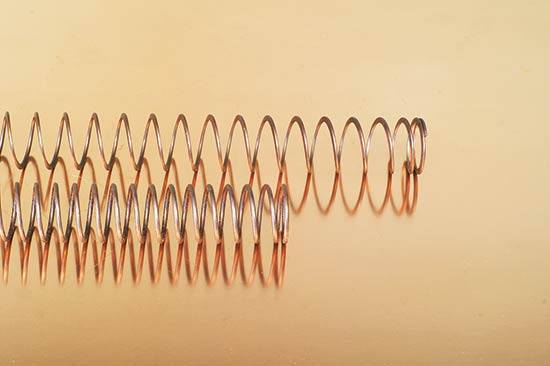

“Springs and rings…” The most commonly malfunctioning parts are all associated with the bolt. The ejector

and extractor springs, and extractor spring in particular. Bolt gas rings are a scheduled-replacement set, or should

be. A complete spare bolt, checked, of course, for proper headspace doesn’t take up much room and can save an outing.

Maybe more.

Home Essentials

If you work on AR-15’s much (as little as once) doing parts replacements and such, it’s easily possible to lose or damage roll pins and springs. Some springs in particular are delicate with respect to kinking. Some are also under a lot of pressure, like the ejector spring, which is also likewise prone to breakage.This was all covered in January’s issue, but keep a roll pin set handy. You might never need any of the specialty pins, but a basic set of No.’s 1, 2, 3, both starters and nib-ended, won’t cost much if you shop for it. Gas-tube pins, especially, are easy to mess up. Review the last article for more, but the pin end polishing, and use of a “slave” punch to guide the pin through, are the best helps. And, when it’s possible, drive the pin all the way through to remove it. That way, it’s more likely you’ll be able to reuse the pin.

Glen follows his own advice for extractor and ejector springs by replacing them on a schedule or upgrading

to chrome-silicon at the start. Upgrade makes more sense. Most other springs can be ignored immediately and

forever after initial installation. Eventually, trigger return and hammer springs need to be replaced, unless, again,

you went to chrome-silicon to start. The hammer spring (above) has lost significant power after 2,500 rounds,

which will increase hammer-fall time.

Routine Replacement

There are parts I replace on a routine. Bolt gas rings, for one, or three actually. They’re cheap enough and way easy to replace. I do it every 1,500 rounds. I’ve had them break nonetheless. Other “supply item” parts? Normally, nothing until/unless it breaks. I always keep a couple of roll pin packs handy, and an assortment of springs. I have spare bolt stops, firing pins, as said, and extractors. Ejectors don’t usually break, but their springs sho’ can.Speaking of breakage: I am a believer in chrome-silicon springs. These perform better than those made of commonly used music wire, but a main (maybe the main) reason is they are far less prone to breakage. They also last for the life of the rifle, in terms of maintaining performance level. Otherwise, I suggest replacing stock-variety springs at 2,500-round intervals. There’s a lot of heat transferred to extractor and ejector springs, which weakens the metal, and that’s generally the reason they break. Chrome-silicon springs endure heat way beyond what a rifle can generate.Standard-variety buffer springs, in my experience, have a maximum OEM-level performance of, at most, 3,000 rounds. A sacked spring is one cause behind the “mystery malfunctions” that befall an AR-15 at around a 4,000 to 5,000 round count. It’s also a solution (along with a thorough cleaning of the bolt-carrier recess housed in the tail end of the bolt). Much happiness arises if you spend up for the preventative bliss of chrome-silicon, or, even better, 17-7 PH stainless.

Shameless Self-Promotion

The preceding is a specially adapted excerpt from The Competitive AR15: Builders Guide, a book by Glen Zediker and Zediker Publishing. For more information, please check out www.ZedikerPublishing.com or www.BuyZedikerBooks.com.

Superior Shooting Systems

800 N. Second St., Canadian TX 79014

(806) 323-9488

www.DavidTubb.com