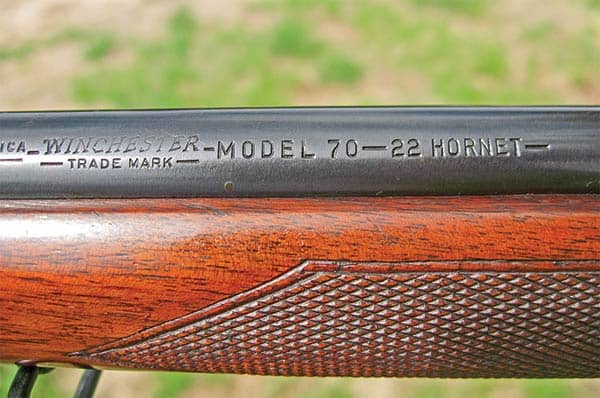

Adapting An Action

Adapting the action and the bolt to the dimensions of the diminutive Hornet involved some brilliant engineering.

The standard, double-column M70 magazine was a simple brazed sheet-metal box holding a machined follower and folded flat spring. For cartridges shorter than the .30-06, a spacer was added to the rear of the box.

In the Hornet, a separate, small, double-column, magazine assembly was manufactured and fitted inside the standard magazine box. This inner assembly contained a Hornet-proportioned follower powered by a music wire spring.

The assembly is slanted forward to separate and properly stack the rimmed Hornet cases. To ensure trouble-free feeding, the front of the assembly sports a long feed ramp that mates with — and blends perfectly — into the standard feed ramp of the action. The assembly holds five cartridges.

The separate Hornet magazine assembly is secured inside the standard magazine box with projecting tabs. The rear of the standard box is itself modified to carry a long, spring-loaded, ejector arm that functions normally through the face of the Hornet bolt. Overall, the Hornet magazine is an elegant but complex assembly that successfully feeds the little cartridges without a hitch.

Adapting the full-size bolt to the Hornet case proved even more complex. Starting with the bolt face, the standard .30-06-type bolt face measures 0.483″. For the Hornet, the face had to be machined to 0.356″. Similarly, the width of the standard extractor claw had to be reduced from 0.407″ to 0.247″. Like all M70 extractors, the face of the miniature claw was beveled to allow the extractor to snap over the rim of a chambered case.

To pick up and feed the rimmed Hornet, a unique spring-loaded cartridge pusher was added to the bottom of the bolt. The cartridge pusher pivots up and down and scoops up the rimmed case from the inner magazine, feeding it into the bolt face and up under the extractor claw.

The next engineering issue to be solved was how to limit the bolt throw of the full-sized bolt to the overall length of the Hornet cartridge, which measures at its maximum, 1.723″.

The solution was what Winchester did to control bolt throw for 18 different cases. They added a bolt stop extension to the bolt, attached to the extractor collar and lining up with the left locking lug. The length of this extension controlled bolt throw when the extension hit the bolt stop as the bolt was opened. Bolt travel for the Hornet was extension-controlled at 2.98″ (for the .375 H&H it was 4.58″).

Finally, the engineers came up with a unique answer to headspacing the little rimmed case. The Model 70 breech was coned like that of the ’03 Springfield. Rather than counter-boring the cone, which they thought would cause feeding problems, they set headspace by having the front edge of the rim just kiss the cone.