Handloading the .45

ACP Part V

Powder-coated Bullets

Today’s latest idea in bullets is powder coating. Several companies offer powder-coated bullets and it’s pretty easy as a do-it-yourself project. Powder-coated bullets are cheaper than jacketed bullets and not as messy as cast-and-lubricated bullets. Powder coating comes in various colors in powder form and a little goes a long way.

And I Helped!

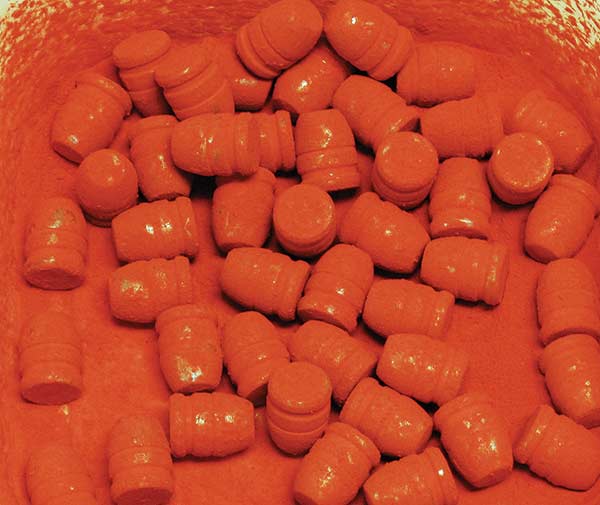

Most do-it-yourselfers follow the “Shake and Bake” method. For this all one needs is a container like an empty Cool Whip, cottage cheese, sour cream container or any other plastic container preferably with a fitted lid. Bullets are placed in this container, I usually go with around 50 at a time and then around a tablespoon of powder is added, the lid placed on and then the shake begins. I like to shake them back and forth and up and down for one to two minutes. They then go in a colander or wire basket to allow the excess powder to be removed.

Now it is time to bake. A toaster oven works best and they can usually be found at secondhand stores. However, I ordered a new one online and it was delivered to me in two days for less than $30. I use wire baskets I make myself. Ace Hardware has rolls of quarter-inch mesh garden fencing lightweight enough to be molded to the shape of a basket and also to be cut very easily with side-cut pliers.

With the bullets in the basket on the tray provided with the toaster oven, it’s now time to bake. My first couple attempts were for learning. I had to be more careful about making sure the bullets were coated properly and also use the right setting of temperature.

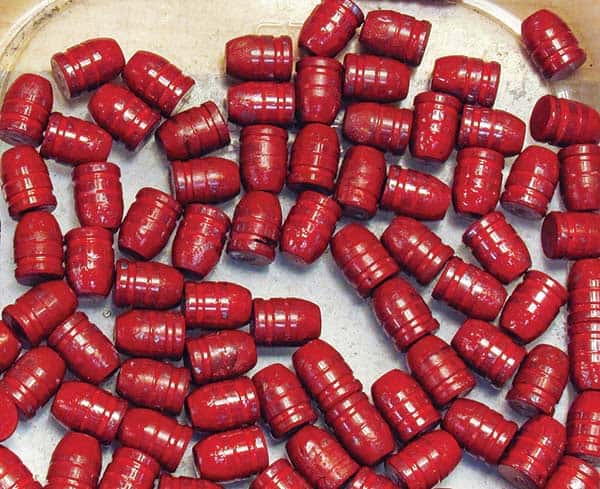

When I set the oven too high — around 450° — some of the bullets actually melted. The proper setting is right at 400° for 10 to 12 minutes. When they are finished baking, the bullets are very hot and need to be handled carefully. It is best to size them as soon as they are cool as they can harden overnight. For sizing I use the very simple Lee Bullet Sizing Die which fits into my Rock Chucker Press along with a bullet punch that fits into the ram much like a shell holder. The bullet is placed on the punch, pushed through the die and goes into a plastic bottle on top of the sizing die. If the bullets are oversize, spraying with something like case-sizing lubricant will make it much easier.

Load Up

As I have mentioned in previous installments, I also use Lee equipment for loading all my .45 ACP rounds. I have been reloading .45 ACP rounds for over 60 years and since I have switched to the following method, I have excellent results and no problems with feeding and chambering rounds except in those very rare cases where a particular pistol simply does not like the bullet profile being used.

I always sort my brass by head stamps and then, using the RCBS RockChucker single-stage press, each case is sized and de-primed with the Lee Undersized Carbide Sizing Die. After this I use the Lee Universal Expanding Die to just kiss the mouth of the case enough to allow the bullet to enter. Using these two dies ensures the tightest possible bullet-to-case fit. This is especially important with .45 ACP loads as there is no crimping groove.

After priming, each case is charged with powder, bullets are seated and then separately taper crimped with the Lee Factory Crimp Die. Powder-coated bullets and jacketed bullets are quite slippery and the use of the Lee Undersized Sizing Die, Lee Universal Expanding Die and the Lee Factory Crimp Die produces ammunition as perfectly as I can make. It also prevents bullets being pushed back into the case during feeding, thus raising pressures. By chronographing each load and watching the results I know this does not happen.

Let’s look at some of the results using Acme Powder-Coated, or “Lipstick” bullets as they are called due to their red color. If you prefer to produce your own powder-coated bullets, you have a choice of several additional colors including black, gray, blue and green. I have been using Acme bullets for the past year in weights of 185, 200 and 230 grains. The 200-grain version is available in three profiles: round-nose, flat-point and semi-wadcutter.

Results

Using the 185 Acme SWC over 5.0 grains of Red Dot in the Ruger SR 1911 Target Model results in a muzzle velocity of 976 fps and a five-shot group at 20 yards of 1-1/2″. The same load in the Springfield Armory Range Officer is slightly slower at 938 fps, however the group tightens up to 1″. The Iver Johnson 6″ Longslide duplicates the results obtained with the Ruger SR 1911.

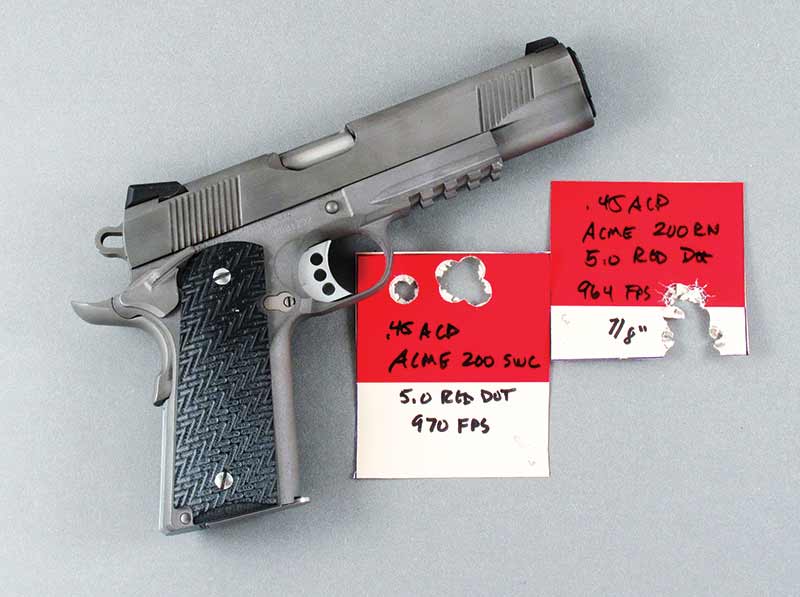

Going up to the 200-grain Acme bullets and using 5.0 grains of Red Dot result in the following — the Ruger SR 1911 Target with the SWC bullet gives a 1-3/8″ group with a muzzle velocity of 960 fps while the Colt Combat Elite shoots into 1-1/4″ with a muzzle velocity of 963 fps. The Colt 1911 Rail Model duplicates this muzzle velocity and shoots into a slightly tighter group. Switching to the 200-grain RN, again with the same 5.0 grains of Red Dot and using the Springfield Armory Range Officer, gives a 1-3/8″ group with a muzzle velocity of 951 fps. My best results with this bullet and powder charge comes from the Colt Rail Model at 964 fps and a 7/8″ group. All of these loads are more than adequately powerful as well as accurate for most applications.

For duplicating Hardball loads, 230-grain round-nose bullets from both Acme and Syntech are used. With 5.2 grains of Sport Pistol, the Ruger SR 1911 Target Model clocks out at 858 fps with a 1-3/8″ group with the Acme 230 while the Syntech over the same powder charge gives 871 fps and a 1-1/4″ group. In the Springfield Armory Range Officer the same two loads are at 848 and 868 respectively with groups of 1-1/8″ and 1-1/2″ also respectively.

Powder-coated bullets are cheaper than jacketed bullets and not as messy as normally cast and lubricated bullets. Six different 1911s were used in testing six different loads and five of these performed flawlessly in both feeding and chambering, while one example did not like the Acme 185 and 200 Semi-wadcutter bullets and refused to feed them. Once again this points to the fact whatever load and whatever pistol is to be used, should be thoroughly tested for reliability before trusting them for any purpose.