Beagling Bullets

The Bulletcaster's Best Friend

A few years ago, I was introduced to long-range cowboy shooting. One of the events involves shooting a lever-action rifle at a steel target 150–200 yards away. While I didn’t participate in the match, I could check out what the other competitors used to make the steel ring. In many cases, they used a Winchester 1886 or similar.

Fast-forward to the height of the COVID pandemic. I was offered an original Winchester 1886 in .40-82, for a price I could afford, and my mind went back to the long-range match. Once I had the rifle in hand, I started searching for the components to make it reach out and make steel ring.

But Wait …

Traditionally the .40-82 used a 0.406″ diameter, round-nose, flat-point lead bullet weighing 240–280 grains. In slugging the barrel of my Winchester, I found it to be just a hair over 0.406″. Many long-range bulletcasters recommend a bullet 0.001″ larger than the groove diameter. Ideally, I needed a bullet dropping at 0.407″ or slightly larger to swage back to 0.407″.

Reading through books and getting advice from Mike Venturino, I felt the Lyman 403169 was the best choice. The kick in the pants was every online retailer was out of stock with no backorder, or one would pop up on an auction site for double or triple the regular retail price!

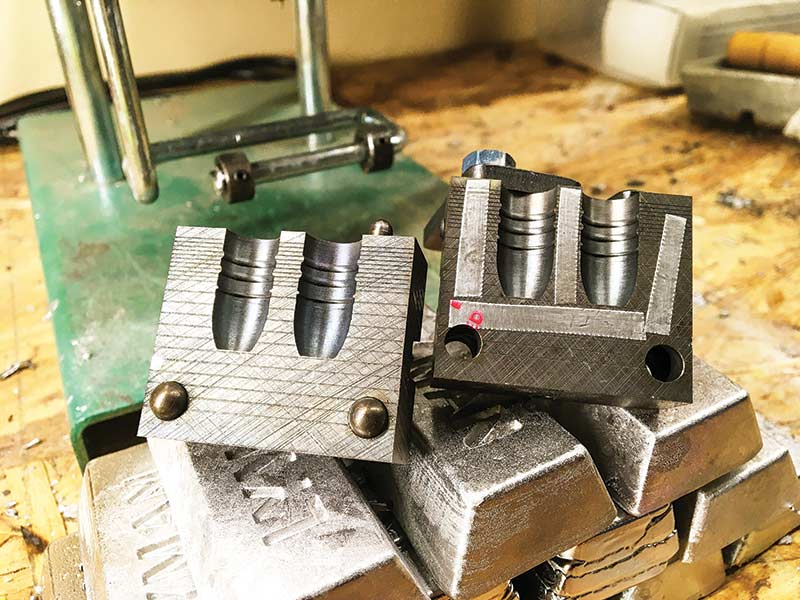

But, Lady Luck smiled on me for once. A friend had a reasonably priced RCBS mold, which cast a similar bullet. When I started casting, Lady Luck stopped smiling and started laughing. Instead of being 0.406″ to 0.408″, the bullets dropped at 0.404″!

While casting a bullet undersized by 0.002″ to 0.003″ doesn’t sound like much, it can mean the difference between holes touching at 50 yards or keyhole bullets all over the target. Some long-range competitors have experienced accuracy issues with bullets just 0.0005″ undersized!

Many shooters assume all gun manufacturers machine their bores and grooves identically. They don’t. While gun makers follow industry standards, those standards have tolerances, meaning the bore can be slightly larger or smaller and still be in the specified tolerance window. Older barrels, made with less-precise machining or with lots of wear, can be on the edge of the tolerance window or even outside it. This is why slugging a barrel is so important. A shooter has to know — not guess — what size bullet they need on a specific gun. If the bullet doesn’t fill the bore fully, the bullet will not fully engage the rifling and the rifle becomes a smoothbore musket. Also, the hot gasses can cause leading as it escapes around the bullet.

So back to my mold issue — the bullets were too small. An obvious choice would be to order a custom mold from a company like Accurate Molds (AccurateMolds.com). But, there were two issues. It seemed every other bullet caster in the country was ordering a custom mold, making the turnaround time longer than I wanted to wait. And custom molds are not cheap; plus I already had a mold. Surely there was a way to make what I had work?

In desperation, I went to the one website I knew would have workable answers, castboolits.gunloads.com. From there I learned how other casters developed solutions to an undersized mold.

The Answer

One somewhat complex solution was to use a bullet cast in the mold as a lapping tool. The answer was to insert a screw into the bullet’s base so a drill motor could spin it in the mold. By applying a lapping compound to the bullet, the drill would spin the bullet and use the abrasive lapping grit to slowly increase the size of the mold cavity. While lapping would work, I don’t particularly appreciate altering any mold because once the material is removed, it’s not growing back. Second, I wanted something involving less work.

Others with more machining equipment than I have made the mold alignment pins adjustable so they could slightly hold the two mold halves apart. With my feeble skills, drilling and tapping sounded like a great way to ruin a mold! Plus, the few reports I read showed limited success.

Then I ran across a posting by John Goins, aka “Beagle.” In it, I found the trials and tribulations John had gone through to increase the size of bullet his mold was dropping. He tried many other techniques, but his experiments ended in using an everyday item at home improvement stores — aluminum foil tape.

John cut thin strips of the aluminum foil tape and used it as stick-on shims! My first thought was, will it work? As much care as casters take to keep their molds burr- and rust-free, how could adding a shim not allow lead flash? I occasionally get lead flashing on my bullets when I don’t grip the mold handles well or when a piece of lead debris keeps the mold from fully closing. In my mind, the foil tape shouldn’t work.

But what if it did? John’s experiments added 0.003″ to 0.004″ to his bullet diameter, which was exactly what I needed!

My next thought: Why didn’t I think of that?! I had several foil tape rolls in my workshop. With reserved excitement, I carefully cut ribbons of foil tape as my lead pot was heating up. I cautiously placed them on one of the mold faces so the mold halves would mate evenly.

Questions

My mind raced with all the things that might go wrong. Would the tape adhesive adhere when the mold was at temperature? Would the tape prevent the mold from venting correctly and would it lead to poor fill out? Would lead pour through the gaps and cause a molten mess on my casting bench?

Like any time I cast, it took a while for the mold to heat up and cast good bullets. But, by the time the bullets were wrinkle-free, I knew the foil tape idea worked. With excitement, I took calipers to my bullets. Using the same alloy as before, my bullets were 0.003″ to 0.004″ larger!

Serendipity! Some casters take it a step further and place tape on both halves of the mold for an even larger bullet. And, if the original bullet is needed, the foil can easily be removed.

I know some of you are going to say the bullets aren’t perfectly round. Very true. But I hate to break this to you — most molds aren’t perfectly round. Lyman states this in their Cast Bullet Handbook. The average bullet mold is not perfect. Yes, some mold makers offer precision molds, but they are expensive and not needed.

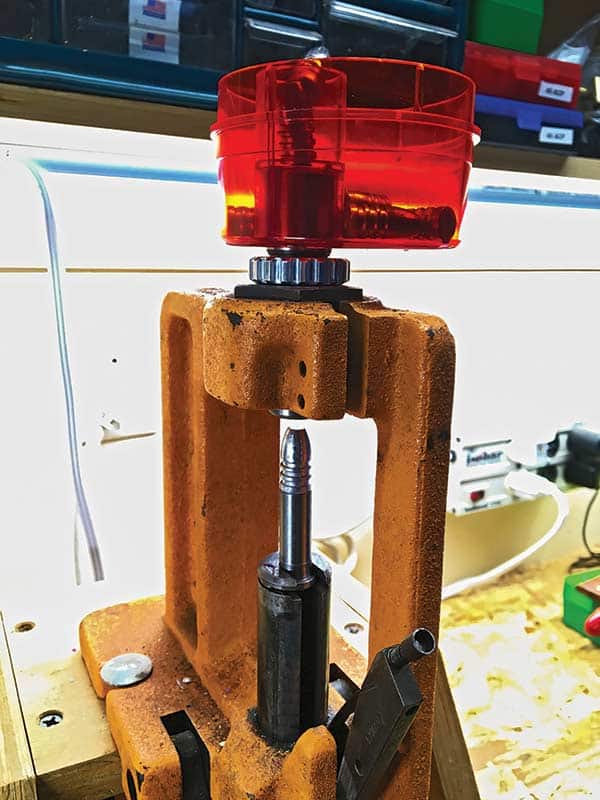

If a shooter wants precision, they slightly over-size their bullets, then swage them to the exact size they want with a sizer. I use the inexpensive Lee sizers for everyday use and the more expensive Lyman and RCBS lube-sizer presses to get the accuracy I want.

Sound easy? You bet! In today’s market, beagling gives new purpose to unused molds so while a beagle is man’s best friend, beagling is a bulletcaster’s best friend, thanks to John “Beagle” Goins.